Top Suppliers of U Purlin Roll Forming Machines for Efficient Production

The Importance of U Purlin Roll Forming Machines in Modern Construction

In the ever-evolving landscape of modern construction, efficiency and precision have become paramount. U purlin roll forming machines have emerged as essential tools for producing U-shaped steel sections, which are crucial components in the framework of various structures, including warehouses, factories, and high-rise buildings. This article explores the significance of these machines, their functionality, and the role of suppliers in this market.

U purlins are widely used in construction due to their ability to provide structural support and stability. Their U-shaped design allows for easy integration with other construction elements, making them ideal for supporting roofs and walls. The demand for U purlins has risen significantly, prompting manufacturers to invest in advanced roll forming technology to meet the needs of the industry.

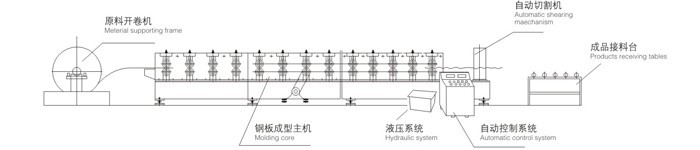

A U purlin roll forming machine is designed to transform flat steel sheets into U-shaped profiles through a sequential forming process. The machine works by feeding the metal sheet into a series of rollers that shape it into the desired U profile. This process not only enhances production efficiency but also ensures uniformity and precision in the dimensions of the final product. Most modern machines are equipped with computer numerical control (CNC) systems, allowing for automated adjustments and reducing human error.

u purlin roll forming machine supplier

Choosing the right supplier for U purlin roll forming machines is critical for any construction business. A reliable supplier can provide high-quality machines that meet international standards, along with comprehensive after-sales support. It is essential to assess the supplier’s reputation, experience, and technical capabilities. Established suppliers often offer a range of machines tailored to different production needs and budget constraints, ensuring that businesses can find a suitable option.

Furthermore, a reputable supplier will provide necessary training and technical support to ensure that the machinery operates efficiently. This investment in training can significantly impact production quality and reduce downtime due to operational errors. Some suppliers also offer customization options, allowing businesses to design machines that cater specifically to their production requirements.

In addition to the manufacturing aspect, U purlin roll forming machine suppliers often provide additional services, such as maintenance and repair. These services are crucial for ensuring the longevity and reliability of the machinery, which, in turn, affects the overall productivity of construction projects.

In conclusion, U purlin roll forming machines play a vital role in modern construction, facilitating the production of essential structural components with efficiency and precision. Selecting the right supplier is crucial for ensuring high-quality machinery and ongoing support. As the construction industry continues to grow, the demand for advanced roll forming solutions will only increase, underscoring the importance of these machines in shaping the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025