Feb . 06, 2025 02:59

Back to list

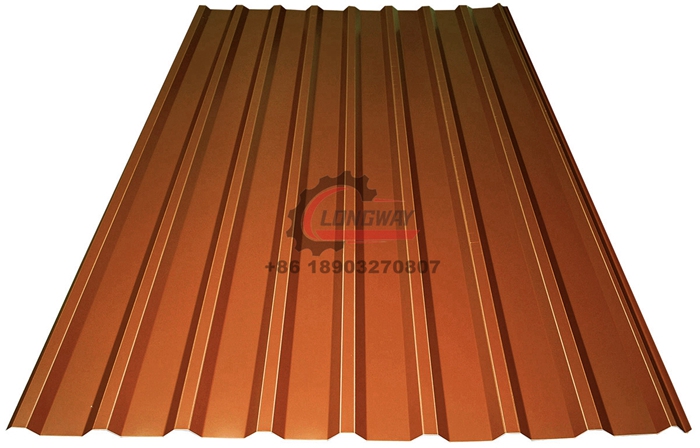

metal roof sheet forming machine

Investing in a metal roof sheet forming machine is a significant decision for any manufacturer or contractor involved in roofing solutions. These machines are sophisticated pieces of equipment capable of transforming flat metal sheets into precise, corrugated roofing panels. Their role in the industry cannot be overstated, given the rising demand for durable, weather-resistant, and aesthetically appealing roofing solutions. Here's a closer look at why a metal roof sheet forming machine is indispensable and how it enhances the production workflow.

Trustworthiness speaks volumes in an era where long-term investments require assurance and reliability. It is not just about acquiring a machine; it is about forming a partnership with the provider. Trust is built on responsive customer service, comprehensive warranties, and transparent communication regarding machine capabilities and limitations. Experienced users often testify to the profound impact of working with trustworthy manufacturers, noting how the collaboration results in enhanced operational reliability and minimized breakdown risks. This attribute is critical in avoiding costly production interruptions and maintaining smooth operations. For businesses involved in roofing, understanding these four pillars—experience, expertise, authoritativeness, and trustworthiness—is vital when selecting a metal roof sheet forming machine. They serve as a guide to making informed purchasing decisions that align with long-term business goals and quality standards. When these elements converge, they not only guarantee a return on investment but also pave the way for establishing a competitive edge in the market. In essence, a metal roof sheet forming machine is not merely an asset; it is a foundation stone for sustained growth and excellence in roofing production. Manufacturers contemplating the integration of such advanced machinery into their operations should leverage these insights to make well-rounded decisions. By focusing on quality, innovation, and partnership, the adoption of a metal roof sheet forming machine can become a transformative milestone in their business journey, enhancing product offerings and expanding market reach.

Trustworthiness speaks volumes in an era where long-term investments require assurance and reliability. It is not just about acquiring a machine; it is about forming a partnership with the provider. Trust is built on responsive customer service, comprehensive warranties, and transparent communication regarding machine capabilities and limitations. Experienced users often testify to the profound impact of working with trustworthy manufacturers, noting how the collaboration results in enhanced operational reliability and minimized breakdown risks. This attribute is critical in avoiding costly production interruptions and maintaining smooth operations. For businesses involved in roofing, understanding these four pillars—experience, expertise, authoritativeness, and trustworthiness—is vital when selecting a metal roof sheet forming machine. They serve as a guide to making informed purchasing decisions that align with long-term business goals and quality standards. When these elements converge, they not only guarantee a return on investment but also pave the way for establishing a competitive edge in the market. In essence, a metal roof sheet forming machine is not merely an asset; it is a foundation stone for sustained growth and excellence in roofing production. Manufacturers contemplating the integration of such advanced machinery into their operations should leverage these insights to make well-rounded decisions. By focusing on quality, innovation, and partnership, the adoption of a metal roof sheet forming machine can become a transformative milestone in their business journey, enhancing product offerings and expanding market reach.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products