Jan . 13, 2025 12:13

Back to list

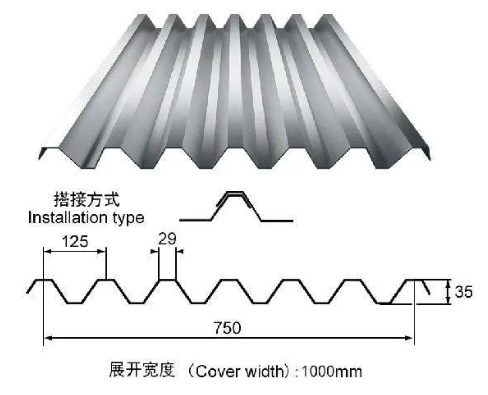

metal roof panel roll forming machine

Metal roof panel roll forming machines are a pivotal innovation in the construction and roofing industry, symbolizing a blend of advanced engineering and intricate design processes. These machines are engineered to create continuous sheet forms, custom-fitted with specific profiles, which revolutionize both small-scale and commercial roofing projects. The growing popularity of metal roofs, fueled by their durability and energy efficiency, has increased the importance of these roll forming machines, making them indispensable tools for industry professionals.

Trustworthiness is a critical factor when it comes to adopting such advanced machinery. The investment in a metal roof panel roll forming machine is significant, and buyers need assurance that the products will deliver as promised. Transparent communication from manufacturers regarding machine capabilities, along with peer reviews and case studies, builds confidence among prospective buyers. Evaluating real-world applications and documented experiences from industry peers can guide potential buyers in making informed decisions. Current market trends indicate an increasing shift towards sustainable and eco-friendly construction solutions. Metal roof panels are known for their recyclability and energy efficiency, often fitted with coatings that reduce heat absorption. By leveraging roll forming machines, manufacturers can ensure these panels are produced to the highest standards, supporting green building certifications and environmentally conscious construction practices. In summary, metal roof panel roll forming machines represent a cornerstone in the evolution of modern construction practices. Their integration into industry processes exemplifies a commitment to superior craftsmanship and environmental stewardship. Through experience, expertise, authoritative backing, and trustworthiness, these machines stand out as essential tools in the builder’s arsenal, promising quality, efficiency, and sustainability in all roofing endeavors.

Trustworthiness is a critical factor when it comes to adopting such advanced machinery. The investment in a metal roof panel roll forming machine is significant, and buyers need assurance that the products will deliver as promised. Transparent communication from manufacturers regarding machine capabilities, along with peer reviews and case studies, builds confidence among prospective buyers. Evaluating real-world applications and documented experiences from industry peers can guide potential buyers in making informed decisions. Current market trends indicate an increasing shift towards sustainable and eco-friendly construction solutions. Metal roof panels are known for their recyclability and energy efficiency, often fitted with coatings that reduce heat absorption. By leveraging roll forming machines, manufacturers can ensure these panels are produced to the highest standards, supporting green building certifications and environmentally conscious construction practices. In summary, metal roof panel roll forming machines represent a cornerstone in the evolution of modern construction practices. Their integration into industry processes exemplifies a commitment to superior craftsmanship and environmental stewardship. Through experience, expertise, authoritative backing, and trustworthiness, these machines stand out as essential tools in the builder’s arsenal, promising quality, efficiency, and sustainability in all roofing endeavors.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products