Jan . 13, 2025 12:02

Back to list

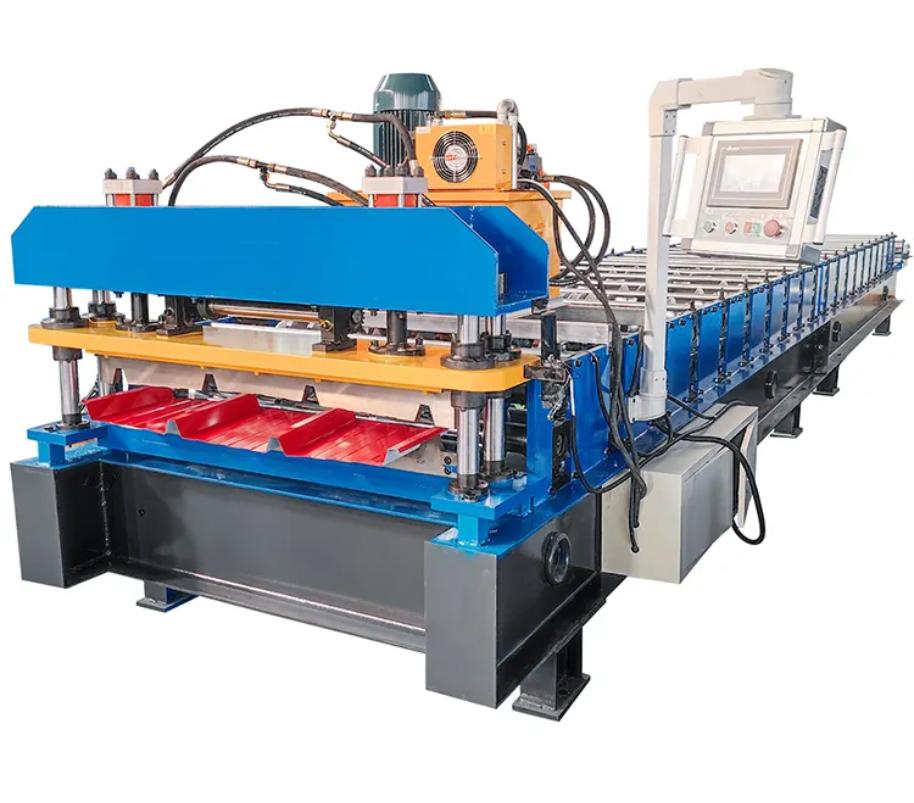

metal roof panel making machine

Metal roof panels have emerged as a popular choice in the construction industry due to their durability, energy efficiency, and aesthetic appeal. However, the production of these panels is a sophisticated process that requires precision and expertise, largely facilitated by the advanced metal roof panel making machines.

Authoritativeness in the manufacturing of metal roof panels comes from a commitment to innovation and adherence to industry standards. Reputable manufacturers are known for their pioneering research, consistently pushing the boundaries of what these machines can do. By collaborating with engineers and staying at the forefront of technological advancements, these companies maintain a competitive edge. Their authoritative presence in the market is reinforced by certifications and recognition from industry bodies, which serve as a testament to their machine’s quality and reliability. Trustworthiness is built through consistent delivery and transparent practices. Manufacturers gain the trust of their clients by providing machines that promise and deliver high-performance outcomes. One crucial aspect is offering excellent customer service that includes installation support, training, and after-sales services. Furthermore, trustworthy manufacturers often provide warranties and guarantees that give customers peace of mind, knowing that they are investing in a product that stands the test of time. The economic advantages of metal roof panel making machines cannot be overstated. By automating several phases of the production process, these machines minimize waste and reduce labor costs, making them a cost-effective solution for manufacturing. This efficiency translates to savings that can be passed on to the consumer, making high-quality metal roofing more accessible to a broader market. In conclusion, metal roof panel making machines are at the heart of producing the robust and visually appealing metal roofs seen on many residential and commercial buildings today. With their advanced technology, they exemplify the perfect blend of expertise, experience, authoritativeness, and trustworthiness. For companies looking to excel in the production of metal roofing, investing in a high-quality metal roof panel making machine is a strategic decision that yields long-term benefits.

Authoritativeness in the manufacturing of metal roof panels comes from a commitment to innovation and adherence to industry standards. Reputable manufacturers are known for their pioneering research, consistently pushing the boundaries of what these machines can do. By collaborating with engineers and staying at the forefront of technological advancements, these companies maintain a competitive edge. Their authoritative presence in the market is reinforced by certifications and recognition from industry bodies, which serve as a testament to their machine’s quality and reliability. Trustworthiness is built through consistent delivery and transparent practices. Manufacturers gain the trust of their clients by providing machines that promise and deliver high-performance outcomes. One crucial aspect is offering excellent customer service that includes installation support, training, and after-sales services. Furthermore, trustworthy manufacturers often provide warranties and guarantees that give customers peace of mind, knowing that they are investing in a product that stands the test of time. The economic advantages of metal roof panel making machines cannot be overstated. By automating several phases of the production process, these machines minimize waste and reduce labor costs, making them a cost-effective solution for manufacturing. This efficiency translates to savings that can be passed on to the consumer, making high-quality metal roofing more accessible to a broader market. In conclusion, metal roof panel making machines are at the heart of producing the robust and visually appealing metal roofs seen on many residential and commercial buildings today. With their advanced technology, they exemplify the perfect blend of expertise, experience, authoritativeness, and trustworthiness. For companies looking to excel in the production of metal roofing, investing in a high-quality metal roof panel making machine is a strategic decision that yields long-term benefits.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products