Jan . 29, 2025 05:05

Back to list

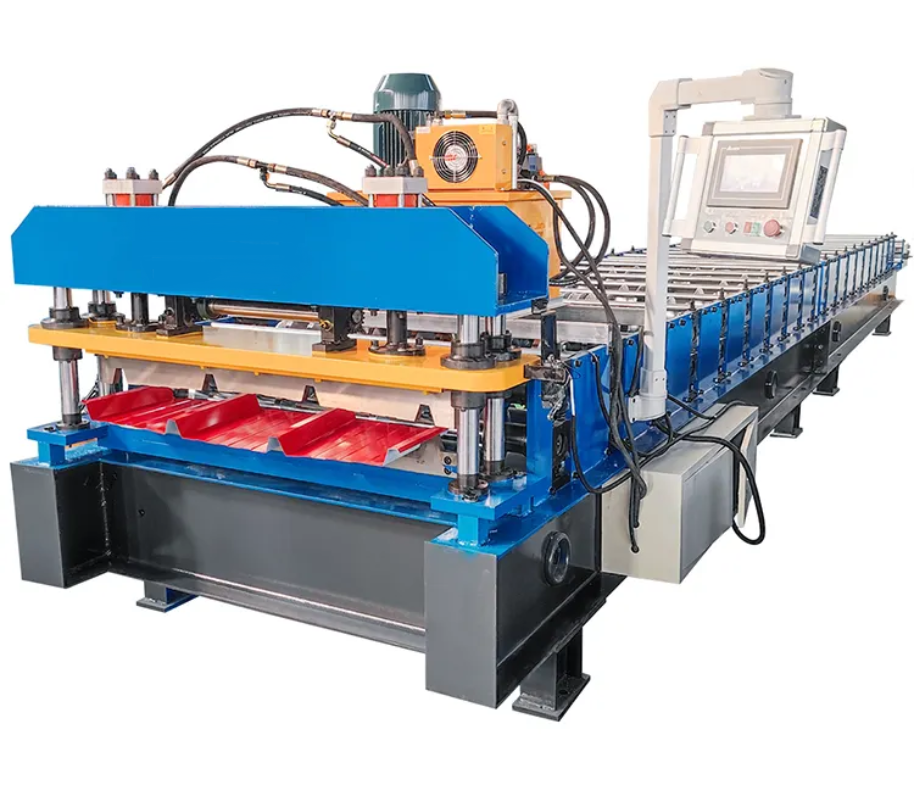

T18 C18 Metal roofing machine Roof sheet forming machine

A metal roofing sheet roll forming machine is an indispensable asset in the construction and manufacturing industries, renowned for transforming vast amounts of metal into roofing sheets with precision and efficiency. This narrative unravels the intricacies of owning and operating such a machine, focusing on the facets of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) to enhance understanding and decision-making for potential buyers and users.

Authoritativeness Achieving authority in the realm of roll forming machines involves a synergy between machine innovation and industrial application. Leading manufacturers, often with decades of involvement in metallurgy and machine technology, design these machines. Their authoritative designs are founded on extensive research and a profound understanding of material science, regulatory requirements, and market demands. Such authority is manifested in patented technologies that enhance machine efficiency, reduce energy consumption, and increase output quality, aspects that distinguish top-tier models in the market. Testimonials from industry experts and endorsements from reputable construction firms further bolster the perceived authority of a specific machine model or brand. Trustworthiness Trust in a metal roofing sheet roll forming machine is cultivated through robust performance, safety features, and reliable after-sales service. Users rely on machines built with durable materials capable of withstanding challenging conditions without faltering. Trusted manufacturers provide warranties, detailed usage guidelines, and comprehensive support services, including regular maintenance schedules and quick-response technical assistance. Operators and companies share their positive experiences through reviews and case studies, emphasizing long-term reliability and customer satisfaction. Building trust also involves transparency about the machine’s capabilities and limitations, ensuring prospective buyers have a realistic expectation and knowledge base to minimize operational risks. In conclusion, owning a metal roofing sheet roll forming machine revolutionizes roofing operations through experienced handling, expert knowledge, authoritative design, and reliable performance. Its role extends beyond mere functionality, representing a strategic investment in construction efficiency and quality assurance. As potential buyers delve into acquiring such machinery, leveraging insights derived from E-E-A-T principles becomes paramount, guiding them towards informed choices that align with their operational objectives and business growth.

Authoritativeness Achieving authority in the realm of roll forming machines involves a synergy between machine innovation and industrial application. Leading manufacturers, often with decades of involvement in metallurgy and machine technology, design these machines. Their authoritative designs are founded on extensive research and a profound understanding of material science, regulatory requirements, and market demands. Such authority is manifested in patented technologies that enhance machine efficiency, reduce energy consumption, and increase output quality, aspects that distinguish top-tier models in the market. Testimonials from industry experts and endorsements from reputable construction firms further bolster the perceived authority of a specific machine model or brand. Trustworthiness Trust in a metal roofing sheet roll forming machine is cultivated through robust performance, safety features, and reliable after-sales service. Users rely on machines built with durable materials capable of withstanding challenging conditions without faltering. Trusted manufacturers provide warranties, detailed usage guidelines, and comprehensive support services, including regular maintenance schedules and quick-response technical assistance. Operators and companies share their positive experiences through reviews and case studies, emphasizing long-term reliability and customer satisfaction. Building trust also involves transparency about the machine’s capabilities and limitations, ensuring prospective buyers have a realistic expectation and knowledge base to minimize operational risks. In conclusion, owning a metal roofing sheet roll forming machine revolutionizes roofing operations through experienced handling, expert knowledge, authoritative design, and reliable performance. Its role extends beyond mere functionality, representing a strategic investment in construction efficiency and quality assurance. As potential buyers delve into acquiring such machinery, leveraging insights derived from E-E-A-T principles becomes paramount, guiding them towards informed choices that align with their operational objectives and business growth.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products