Feb . 10, 2025 09:26

Back to list

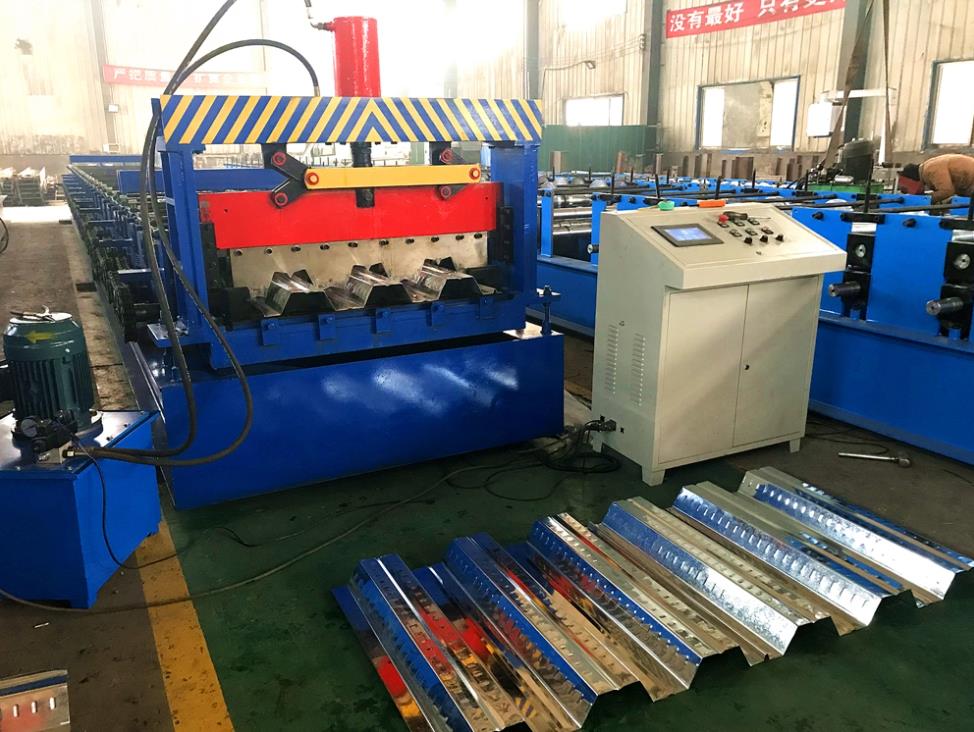

metal roll forming machine suppliers

Selecting the right metal roll forming machine supplier is an essential decision for manufacturers aiming to ensure quality and efficiency in their production processes. A metal roll forming machine transforms metal sheet coils into desired shapes with precision and efficiency, making them critical components in various industries including automotive, construction, and appliance manufacturing. Here, we delve deep into the experience, expertise, authoritativeness, and trustworthiness of metal roll forming machine suppliers to help you make informed decisions.

Further, when considering product-related specifics, ensure that the metal roll forming machines incorporate quality materials and components, as these will impact durability and performance. Machines built with high precision engineering and strict quality controls are more likely to sustain rigorous use without significant downtime. Suppliers should also be willing to explain the advantages of their machines, like energy efficiency, ease of operation, and maintenance requirements. The importance of technological integration cannot be overstated. Advanced roll forming machines with automation capabilities and smart technology integration can offer significant advantages in terms of productivity and quality. Suppliers who are at the forefront of such innovations can provide machines that are future-proof, accommodating growth and technological progression in your industry. Customization and flexibility are also crucial. Businesses have unique production requirements, and the ability of a supplier to customize their machines to fit these needs can greatly enhance efficiency and product quality. Suppliers should encourage collaborative engagements where customization is seen as a joint effort to achieve optimal results. In conclusion, choosing the right metal roll forming machine supplier requires a thorough evaluation of their experience, expertise, authoritativeness, and trustworthiness. Engaging a supplier who excels in these areas will not only enhance the quality and efficiency of your production processes but also contribute positively to your company’s long-term success. By prioritizing suppliers that offer robust technical support, advanced technology, and a customer-oriented approach, you can advance confidently in your manufacturing endeavors.

Further, when considering product-related specifics, ensure that the metal roll forming machines incorporate quality materials and components, as these will impact durability and performance. Machines built with high precision engineering and strict quality controls are more likely to sustain rigorous use without significant downtime. Suppliers should also be willing to explain the advantages of their machines, like energy efficiency, ease of operation, and maintenance requirements. The importance of technological integration cannot be overstated. Advanced roll forming machines with automation capabilities and smart technology integration can offer significant advantages in terms of productivity and quality. Suppliers who are at the forefront of such innovations can provide machines that are future-proof, accommodating growth and technological progression in your industry. Customization and flexibility are also crucial. Businesses have unique production requirements, and the ability of a supplier to customize their machines to fit these needs can greatly enhance efficiency and product quality. Suppliers should encourage collaborative engagements where customization is seen as a joint effort to achieve optimal results. In conclusion, choosing the right metal roll forming machine supplier requires a thorough evaluation of their experience, expertise, authoritativeness, and trustworthiness. Engaging a supplier who excels in these areas will not only enhance the quality and efficiency of your production processes but also contribute positively to your company’s long-term success. By prioritizing suppliers that offer robust technical support, advanced technology, and a customer-oriented approach, you can advance confidently in your manufacturing endeavors.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products