Feb . 10, 2025 09:32

Back to list

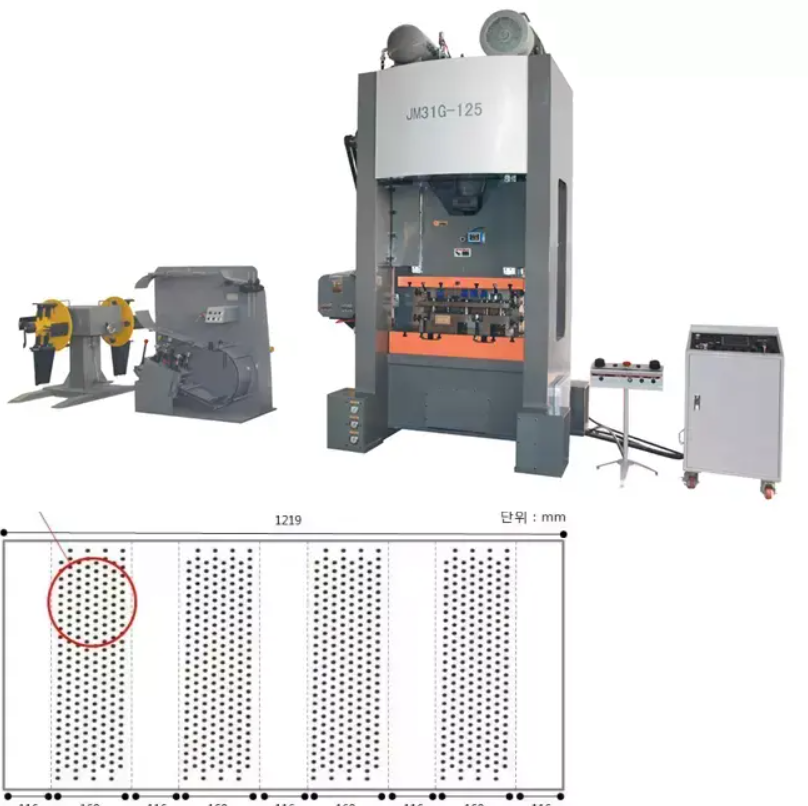

metal sheet roof roll forming machine

A metal sheet roof roll forming machine is an integral asset in the industrial manufacturing landscape, known for its efficiency and precision in converting metal coils into roofing panel profiles. As a testament to modern engineering, these machines not only enhance production capabilities but also bolster safety and quality standards across industries that rely heavily on durable roofing solutions.

Trust in the metal sheet roof roll forming machine is also derived from the continuous innovation that manufacturers invest in. Cutting-edge advancements are frequently implemented, from precision-engineered cutting systems to advanced software for design customization and production optimization. The integration of IoT technologies allows operators to monitor real-time performance data, preemptively address maintenance needs, and streamline production schedules, all of which contribute to reducing operational costs and minimizing unexpected downtimes. Furthermore, the adaptability of roll forming machines is a key aspect that boosts their trustworthiness. Regardless of the diversity in client requirements, these machines can swiftly adjust to produce varying profiles and dimensions. This versatility makes them a preferred choice for industries ranging from commercial construction to bespoke architectural applications. Investing in such adaptable machinery not only offers a competitive edge but also ensures that businesses are well-prepared to meet evolving market demands. An additional benefit of using metal sheet roof roll forming machines is their environmental efficiency. By optimizing the metal forming process, these machines significantly reduce waste during production. The reduction in waste aligns with sustainable manufacturing practices, minimizing the carbon footprint associated with traditional methods. Consequently, businesses can advertise not only the quality of their product but also their commitment to environmentally responsible manufacturing practices. In summation, metal sheet roof roll forming machines represent the pinnacle of modern manufacturing technology, offering unmatched precision, reliability, and efficiency. Their integration into production processes elevates operational capabilities, aligns with stringent quality and environmental standards, and stands as a testament to industrial progress. These machines are not merely tools; they are fundamental components that drive innovation, extend operational lifespan, and enhance the overall quality of roofing solutions across various sectors.

Trust in the metal sheet roof roll forming machine is also derived from the continuous innovation that manufacturers invest in. Cutting-edge advancements are frequently implemented, from precision-engineered cutting systems to advanced software for design customization and production optimization. The integration of IoT technologies allows operators to monitor real-time performance data, preemptively address maintenance needs, and streamline production schedules, all of which contribute to reducing operational costs and minimizing unexpected downtimes. Furthermore, the adaptability of roll forming machines is a key aspect that boosts their trustworthiness. Regardless of the diversity in client requirements, these machines can swiftly adjust to produce varying profiles and dimensions. This versatility makes them a preferred choice for industries ranging from commercial construction to bespoke architectural applications. Investing in such adaptable machinery not only offers a competitive edge but also ensures that businesses are well-prepared to meet evolving market demands. An additional benefit of using metal sheet roof roll forming machines is their environmental efficiency. By optimizing the metal forming process, these machines significantly reduce waste during production. The reduction in waste aligns with sustainable manufacturing practices, minimizing the carbon footprint associated with traditional methods. Consequently, businesses can advertise not only the quality of their product but also their commitment to environmentally responsible manufacturing practices. In summation, metal sheet roof roll forming machines represent the pinnacle of modern manufacturing technology, offering unmatched precision, reliability, and efficiency. Their integration into production processes elevates operational capabilities, aligns with stringent quality and environmental standards, and stands as a testament to industrial progress. These machines are not merely tools; they are fundamental components that drive innovation, extend operational lifespan, and enhance the overall quality of roofing solutions across various sectors.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products