Metal Deck Roll Forming Equipment Provider for High-Quality Structural Solutions.

Metal Deck Roll Forming Machine Manufacturers An Overview

In the realm of modern construction and structural engineering, the demand for high-quality metal deck roll forming machines (RFM) has witnessed significant growth. These specialized machines are essential for producing metal deck sheets used in floors, roofs, and other applications, offering superior strength and durability. With the increasing adoption of metal decking in the building industry, the role of reliable manufacturers in delivering efficient and innovative roll forming machines becomes paramount.

What is a Metal Deck Roll Forming Machine?

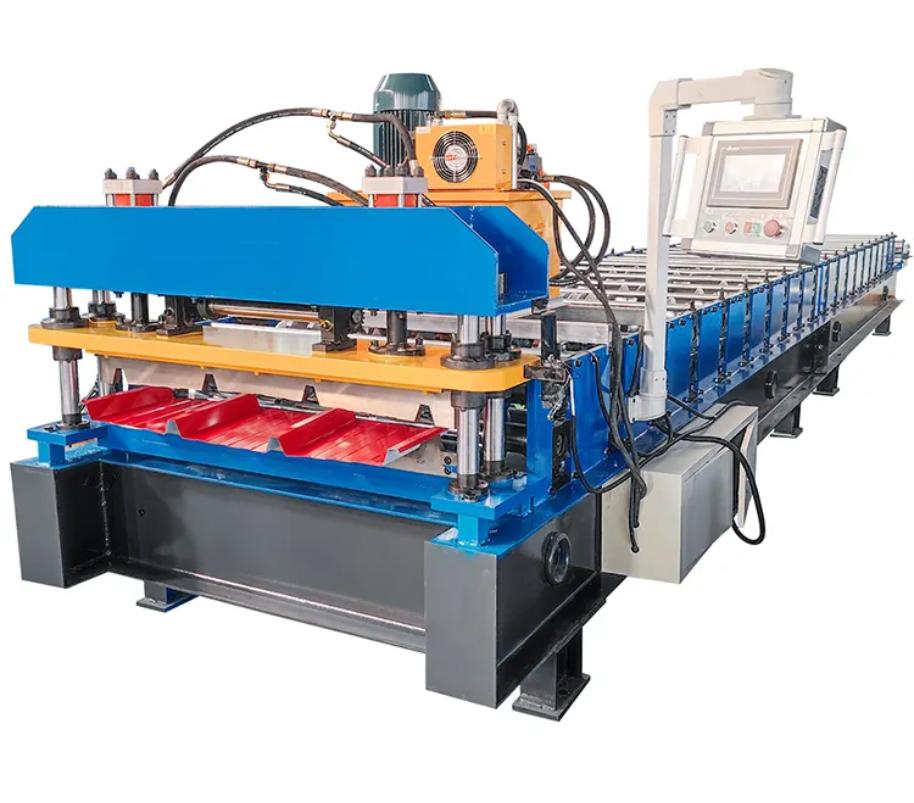

A metal deck roll forming machine is a type of machinery designed to shape and profile metal sheets into deck panels through a continuous process. The raw material, typically galvanized or pre-painted steel sheets, is fed into the machine where a series of rollers progressively form the metal into a predetermined profile. The end products, known as metal decking, are widely used in various construction projects, including commercial buildings, industrial facilities, and residential properties.

Key Features of Roll Forming Machines

1. Durability and Precision One of the key advantages of metal deck roll forming machines is their ability to produce consistent, high-quality products with precise dimensions. This precision is vital in construction, where even minor discrepancies can lead to significant structural issues.

2. High Production Efficiency Modern roll forming machines are designed for high-speed production, capable of producing hundreds of sheets per hour. This efficiency makes them ideal for large-scale construction projects where time and cost savings are crucial.

3. Customization Capabilities Manufacturers often offer customizable solutions to meet specific project requirements. This includes the ability to produce different deck profiles and thicknesses, enabling builders to select the best materials for their needs.

4. Automated Systems Many leading metal deck roll forming machine manufacturers incorporate advanced automation technologies into their systems. Automation minimizes manual intervention, reducing labor costs while enhancing safety and efficiency.

Choosing the Right Manufacturer

metal deck roll forming machine manufacturer

When selecting a manufacturer for metal deck roll forming machines, several factors should be considered

1. Experience and Expertise A manufacturer with extensive experience in the industry will likely offer better insights into the specific needs of construction projects. Their expertise can translate into superior machine design and functionality.

2. Quality Assurance It is crucial to choose manufacturers that adhere to stringent quality control processes. Machines should meet international standards, ensuring reliability and consistency in production.

3. After-Sales Support Comprehensive support services post-purchase, including maintenance and repair, can significantly impact the longevity and performance of the equipment. Choose a provider known for excellent customer service and support.

4. Innovative Technology The construction industry is evolving, and so should the technology used in roll forming machines. Manufacturers that invest in research and development often provide machines with the latest features, increasing efficiency and reducing waste.

The Future of Metal Decking and Roll Forming Machines

As sustainability becomes a key focus in construction, metal decking presents an eco-friendly option due to its recyclability. This growing emphasis on sustainable practices implies a heightened demand for efficient metal deck roll forming machines. Manufacturers who can innovate and improve their machinery to produce greener products will likely have an advantage in the marketplace.

The evolution of smart manufacturing, including the Internet of Things (IoT), will also shape the future of metal deck roll forming machines. Integration of IoT technologies can enhance machine monitoring, predictive maintenance, and overall production management, leading to more efficient operations.

Conclusion

In conclusion, metal deck roll forming machines are indispensable in today’s construction landscape, providing the efficiency and precision required for high-quality metal decking. As the demand for these machines continues to grow, selecting the right manufacturer becomes critical to ensuring project success. By considering factors such as experience, quality assurance, after-sales support, and technological innovation, builders and contractors can make informed choices that will benefit their projects and contribute to a more sustainable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025