Leading Manufacturer of High-Quality Sheet Metal Roll Forming Equipment

Sheet Metal Roll Forming Machine Manufacturer An Overview

The manufacturing industry has seen remarkable advancements in technology, and one such innovation that has transformed the metalworking sector is the sheet metal roll forming machine. These machines are quintessential for producing various metal profiles used in construction, automotive, and appliance manufacturing sectors. As a sheet metal roll forming machine manufacturer, understanding the nuances of production, technology, and market demand is crucial.

What is a Sheet Metal Roll Forming Machine?

A sheet metal roll forming machine is designed to shape and convert flat metal sheets into complex profiles through a sequence of forming stations. The process involves feeding a flat sheet into a series of rollers that progressively bend the metal into the desired shape. Common products created by roll forming machines include roof panels, wall sections, gutters, and even automotive components.

The Manufacturing Process

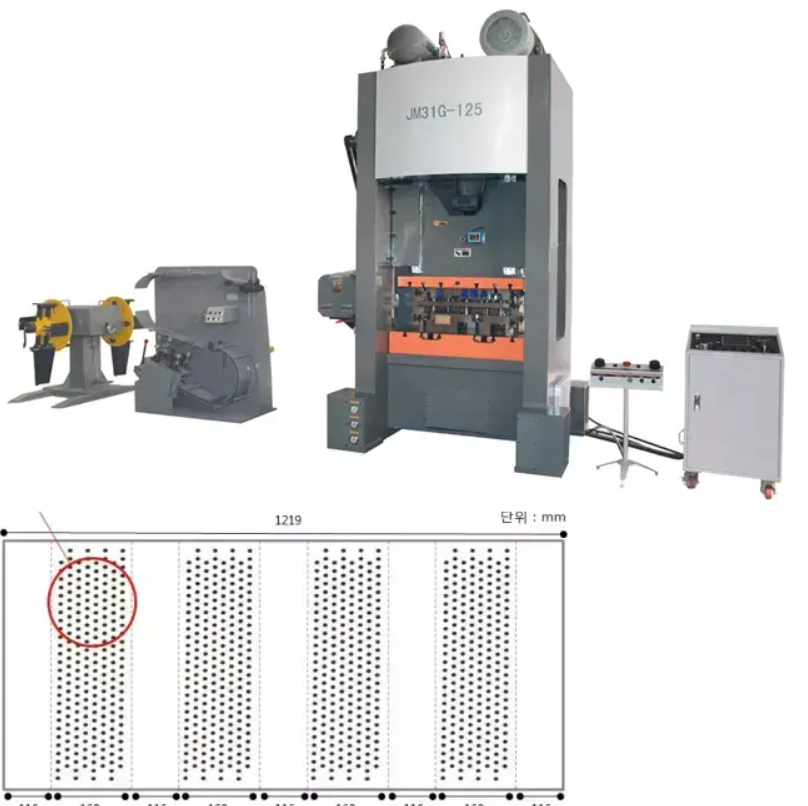

The typical workflow in a roll forming production line begins with the material preparation stage. Steel, aluminum, or other metal sheets are initially cut to size before being fed into the machine. The machine consists of multiple rollers, each designed to perform a specific bending operation. As the metal sheet progresses through the rolling stations, it gradually takes on the desired profile.

Precision is critical in this process. High-quality roll forming machines are equipped with advanced controls and automation systems that ensure accuracy in dimensions and tolerances. This precision results in finished products that meet stringent industry standards, enhancing their usability in various applications.

Advantages of Roll Forming

One of the primary benefits of using a sheet metal roll forming machine is efficiency. Once set up, these machines can produce large volumes of parts at high speeds, significantly reducing production time compared to other methods. Moreover, roll forming minimizes waste material since it utilizes the entire sheet of metal, making it a cost-effective solution.

sheet metal roll forming machine manufacturer

Additionally, roll-formed products are known for their durability and strength. The continuous forming process enhances the structural integrity of the metal profiles, making them suitable for demanding applications like construction and industrial use.

Market Demand and Trends

The demand for sheet metal roll forming machines is projected to grow, driven by the increasing need for metal components across various industries. The construction sector, in particular, has seen substantial growth, with roll-formed metal profiles being favored for their lightweight yet robust nature.

Emerging trends indicate a shift towards automation and smart manufacturing. Modern roll forming machines are increasingly incorporating Industry 4.0 technologies, such as IoT sensors and AI-driven analytics, enhancing operational efficiency and minimizing downtime. Manufacturers who adopt these technologies can not only improve their production capabilities but also offer better maintenance and support services.

Choosing the Right Manufacturer

When selecting a sheet metal roll forming machine manufacturer, several factors require consideration. Potential buyers should assess the manufacturer’s experience, reputation, and the technological features of their machines.

Customization is another critical aspect. The ability to design a machine tailored to specific production needs can significantly enhance productivity. Manufacturers that offer comprehensive after-sales support, including installation, training, and maintenance, can also provide added value, ensuring seamless operation of the equipment.

Conclusion

In conclusion, the role of a sheet metal roll forming machine manufacturer is pivotal in today's manufacturing landscape. With the continuous evolution of technology and growing market demands, the future of roll forming appears promising. Manufacturers focusing on innovation, efficiency, and customer satisfaction are well-positioned to thrive in this competitive industry, contributing significantly to the advancement of metalworking processes and applications. As industries continue to expand, the importance of high-quality sheet metal roll forming machines will undoubtedly remain a cornerstone of production capabilities around the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025