Metal Roof Panel Machine | High-Speed, Precision Forming

Inside the 750 Trapezoidal Cladding Wall Panel Forming Machine: Notes From the Shop Floor

If you’re weighing up a metal roof panel machine purchase right now, you’re not alone. Demand has been quietly surging thanks to logistics parks, agri sheds, and those surprisingly stylish steel-clad retail boxes popping up in second-tier cities. I’ve toured a few lines this year—including the 750 Trapezoidal Cladding wall panel forming machine from Shibawuxing Village, Bo Town, Cangzhou, Hebei—and here’s the straight story, warts and all.

What’s trending (and why it matters)

The trend line is clear: faster changeovers, tighter tolerances, and smarter diagnostics. Builders want consistent 750 mm effective cover panels with less scrap. Owners want PLCs that don’t require a PhD to operate. Meanwhile, specifiers are pushing for panels formed from G550 high-strength steel and AZ-coated coils to hit coastal durability targets. To be honest, five years ago you didn’t hear that much about EN 10346 or ASTM A653 on job sites—now it’s routine chatter.

Core specs (real-world, not brochure fluff)

| Model | 750 Trapezoidal Cladding wall panel forming machine |

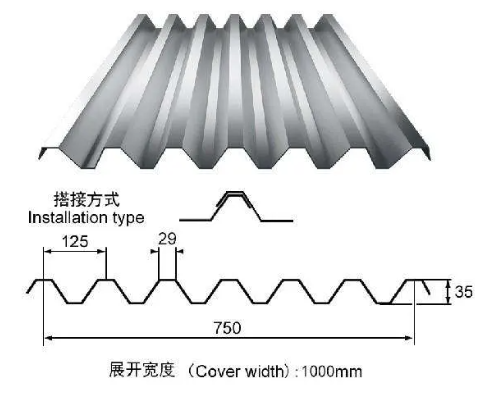

| Effective cover width | 750 mm (profile dependent) |

| Input coil width | ≈1000–1250 mm (project-specific) |

| Thickness range | 0.3–0.8 mm (PPGI/GI/GL; real-world use may vary) |

| Forming stations | 14–18 (customizable) |

| Line speed | 10–20 m/min (material + cut length dependent) |

| Drive & power | Chain/gear; main motor ≈5.5–7.5 kW; hydraulic cut ≈3 kW |

| Cutting accuracy | ±0.5 mm over 6 m (typical) |

| Control | PLC (Siemens/Delta), HMI touchscreen |

Process flow and quality checkpoints

Decoiling → leveling → roll forming → hydraulic cutting → run-out → packing. Materials: galvanized (ASTM A653), galvalume (EN 10346, DX51D+AZ), pre-painted (PPGI). Rollers are typically 45# steel with hard chrome; good lines spec GCr15 with quench to HRC 58–62 for longer life. We’ve seen operators verify coil coating per ISO 2808 and do hardness checks per ISO 6508-1. A quick note: keep your squareness check and pit gauge routine—small habits add years of service.

Expected service life? With basic lubrication and alignment audits every 2,000 hours, 10–15 years is normal. Bearings fail early if you ignore coil edge-burrs—seen it too many times.

Where it’s used

- Industrial roofs and façades (logistics, light manufacturing)

- Agricultural sheds, poultry, dairy—easy wash-down panels

- Coastal warehouses with AZ-coated coils for corrosion resistance

- Retrofit cladding on retail boxes and community sports halls

Why this metal roof panel machine stands out

Faster die swaps, tidy cable management, and a hydraulic unit that doesn’t moan under continuous duty. Many customers say the HMI recipes save half a shift during profile tweaks. Certifications typically include ISO 9001 and CE (Machinery Directive)—ask for the test sheet, don’t just take the sticker at face value.

Vendor snapshot (be picky)

| Vendor | Certs | Lead Time | Warranty | Customization |

|---|---|---|---|---|

| LW Roll Forming (Cangzhou, Hebei) | ISO 9001, CE (docs on file) | ≈25–40 days | 12–18 months | High (rollers, PLC, decoiler options) |

| Regional Integrator | ISO 9001 (varies) | ≈30–60 days | 12 months | Medium (controls + decoiler) |

| Imported OEM | CE/UKCA | ≈8–12 weeks | 12–24 months | Medium–High (costly) |

Customization and options

Popular tweaks: hydraulic decoiler (5–7T), servo flying shear for tighter cut accuracy, embossing roller, oiling unit, and profile change kits. Address and origin matter for spare parts: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE—logistics from Tianjin port is usually smooth.

Field notes and case snippets

- Malaysia logistics hub: switched to metal roof panel machine line speed 18 m/min; scrap cut by ≈12% after PLC recipe tuning.

- Nebraska agri co‑op: 0.6 mm AZ panels; winter operation OK after swapping to low-temp hydraulic oil.

- Polish retail box retrofit: tolerance ±0.4 mm over 4.2 m using servo shear—architects finally smiled.

Feedback is consistent: “stable tracking, decent after-sales, and the HMI doesn’t fight you.” That last part is underrated.

Standards, testing, and data you should ask for

Request material certs (ASTM A653 or EN 10346), safety conformity (ISO 12100; CE per 2006/42/EC), coating checks (ISO 2808), and a factory FAT sheet showing speed vs. thickness. If a vendor hesitates, you’ve got your answer.

Citations

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated: https://www.astm.org/a0653_a0653m.html

- EN 10346 – Continuously hot-dip coated steel flat products: https://standards.iteh.ai/catalog/standards/cen/6f3b6e73-8f7e-4c3d-8f9c-6f8b5ea27a66/en-10346

- ISO 9001 – Quality management systems: https://www.iso.org/standard/62085.html

- ISO 12100 – Machinery safety: https://www.iso.org/standard/51528.html

- ISO 2808 – Paints and varnishes, film thickness: https://www.iso.org/standard/65774.html

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025