Metal Gutter Downspout Pipe Forming Machine | Fast, PLC

Field Notes on the Metal Gutter Downspout Pipe Forming Machine buyers actually want

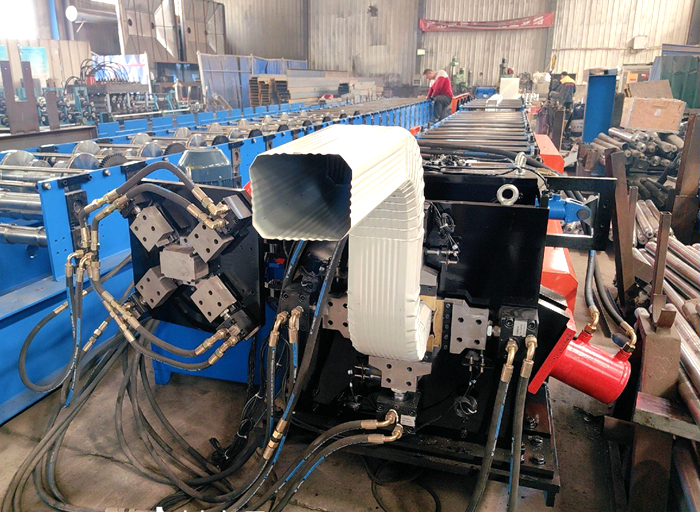

I was in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE not long ago—dusty yard, coffee in paper cups, and a line humming at 16 m/min. That’s where this line was running square 3×4 pipes in the morning and switched to 100 mm round after lunch. Sounds routine, but the setup time was under 40 minutes, which, to be honest, is where real ROI hides.

What’s trending (and what’s just marketing)

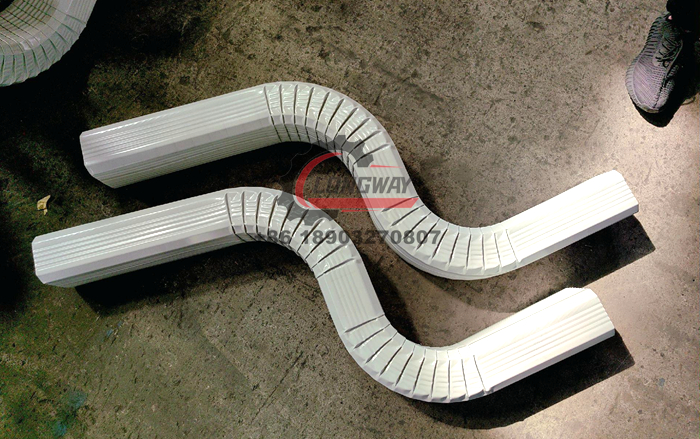

Three things I keep seeing: smarter cassette systems (for round ↔ square changes), gentler roll geometry to reduce paint micro-cracking, and basic data logging—nothing fancy, just coil batch + meter counts. Actually useful. Many customers say the biggest surprise is how consistent seam tightness gets when the infeed and leveling are dialed-in; fewer leaks, fewer callbacks.

Core specifications buyers ask first

| Profiles | Round 100 mm; Square 3×4 in (cassette change) |

| Materials | GI/PPGI, Aluminum 3003/3105, Copper (on request) |

| Thickness range | ≈0.40–0.70 mm (real-world use may vary by alloy/coating) |

| Yield strength | 235–550 MPa |

| Line speed | 10–20 m/min (≈16 m/min typical for coated steel) |

| Stations | 18–24 passes depending on profile set |

| Cutting | Hydraulic shear; flying cut optional |

| Control | PLC (Siemens/Delta), encoder length control ±0.5 mm/6 m |

| Power | ≈11–18 kW total installed |

Process flow, testing, service life

Coil loading → decoiling → leveling → precision roll forming → (optional) seam lock/TIG stitch for heavy copper → embossing ribs (optional) → hydraulic/flying cut → crimping/necking → outlet punching (if required) → inline QC. Methods are textbook, but the roll flower here is kinder to PPGI coatings, which is crucial in coastal jobs.

Testing: base metal per ASTM A653 (GI), coating bend tests T-bend, salt spray ASTM B117 (typical 500–1,000 h for premium PPGI), and dimensional checks with go/no-go gauges. CE Machinery Directive conformity and ISO 9001 quality routines are standard. Typical service life: 20–30 years for galvanized/PPGI in suburban exposure; copper often outlasts the roof.

Where it’s used and why it matters

Residential subdivisions, light commercial strips, agribuildings. The big advantage of the Metal Gutter Downspout Pipe Forming Machine is repeatability: straightness and a tight longitudinal lock reduce installers’ on-site wrestling. Less wrestling = faster installs, fewer dents, fewer callbacks. Simple.

Vendor landscape (my practical take)

| Vendor | Lead time | Customization | Warranty | Certifications | After-sales |

|---|---|---|---|---|---|

| LW (Cangzhou) | ≈35–55 days | Round/3×4 cassettes, logo emboss, special alloys | 18 months | CE, ISO 9001 | Remote + on-site commissioning |

| Local Fabricator | 20–40 days | Moderate; depends on tooling shop | 12 months | Varies | Good proximity; limited spares stock |

| Importer-only | Stock/unknown | Low | 6–12 months | Claims vary | Third-party service |

Customization and nice-to-haves

- Cassette swap between round 100 mm and 3×4 in square

- Embossing ribs, logo stamping, protective PE film

- Voltage: 380 V/50 Hz, 415 V/50 Hz, or 460 V/60 Hz

- Outlet punching module and auto crimper

- Material kits tuned for copper or 3105 aluminum

Operators told me the foot-switch and clear fault codes matter more than glossy brochures. I guess that’s shop-floor wisdom.

Mini case study

A Southeast Asia roofing contractor ramped to ≈5,200 m/week in month one. Scrap dropped from 2.8% to 1.2% after roll alignment and entry guide tweaks. Salt spray on their PPGI coil hit 750 h (ASTM B117) before creep—respectable. Installers reported 14% faster downspout hangs due to cleaner crimping from the Metal Gutter Downspout Pipe Forming Machine.

Compliance quick list

Machinery CE (2006/42/EC), ISO 9001 quality management, base metal per ASTM A653 for GI, coating durability via ASTM B117, and installation compatibility with common gutter standards (EN 612 equivalents, where specified). If you’re in a marine zone, ask for upgraded roll coatings and a slower line speed recipe—surprisingly effective at preserving finish.

References

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025