Efficient Production of Keel Channels with Advanced Roll Forming Machinery

The Keel Channel Roll Forming Machine Revolutionizing Steel Production

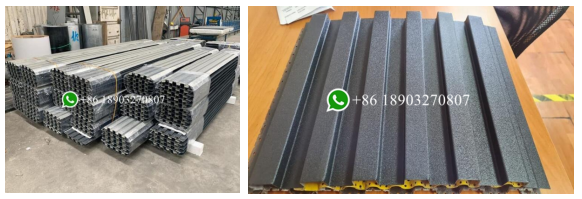

The keel channel roll forming machine represents a significant advancement in the field of metal forming technology. This specialized machinery is designed to produce high-quality keels and channels used in construction, automotive, and other industries requiring robust structural components. With the increasing demand for precision and efficiency in manufacturing, the keel channel roll forming machine stands out as an essential tool for modern fabricators.

At its core, the keel channel roll forming machine operates through a continuous process that transforms flat steel strips into shaped profiles. The machine incorporates a series of rollers that gradually bend and form the metal into the desired channel shape. The rolls are strategically designed to handle various thicknesses and widths of the material, ensuring versatility and adaptability. This capability allows manufacturers to create a wide range of channel sizes tailored to specific project requirements.

One of the key advantages of using a keel channel roll forming machine is the high efficiency it offers compared to traditional manufacturing methods. The continuous roll forming process not only reduces labor costs but also minimizes material waste. The machine operates at high speeds, allowing for the mass production of channels without compromising on the precision of the dimensions. This efficiency translates into shorter lead times and the ability to meet tight project deadlines, which is particularly crucial in industries such as construction.

keel channel roll forming machine

Another significant benefit of the keel channel roll forming machine is its capacity for automation. Modern machines are equipped with advanced technology, including computer numerical control (CNC) systems. These systems enable operators to program various profiles and specifications, ensuring consistent production quality. Automation also reduces the risk of errors that can occur in manual processes, further enhancing the reliability of the final products.

In terms of applications, keel channels produced by the roll forming machine are widely used in constructing frameworks, support structures, and even decorative elements in buildings. The strength and durability of channel profiles make them ideal for use in heavy-duty applications, such as in the automotive industry, where they contribute to the structural integrity of vehicles. Additionally, their lightweight nature allows for ease of handling and installation, making them a preferred choice among contractors.

Maintenance of the keel channel roll forming machine is also straightforward, which contributes to its longevity and reliability. Regular checks and servicing ensure that the rollers remain aligned and that the machine operates smoothly. With proper care, these machines can provide consistent performance for many years, making them a wise investment for manufacturers.

In conclusion, the keel channel roll forming machine is a vital piece of equipment in the manufacturing landscape. Its ability to produce high-quality, precise channel profiles efficiently makes it indispensable for companies looking to optimize their production processes. As industries continue to evolve, embracing technologies that enhance productivity and reduce costs, the keel channel roll forming machine will undoubtedly play a crucial role in shaping the future of metal fabrication.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025