corrugated roll forming machine for sale company

Corrugated Roll Forming Machine for Sale A Comprehensive Overview

In the modern manufacturing landscape, the demand for efficient and high-quality production processes is ever-increasing. Among various machinery that cater to this need, the corrugated roll forming machine stands out for its ability to produce durable and lightweight corrugated sheets. This has led to a growing interest in purchasing these machines, especially from manufacturers looking to optimize their production capabilities. This article explores the features, advantages, and considerations involved in investing in a corrugated roll forming machine.

What is a Corrugated Roll Forming Machine?

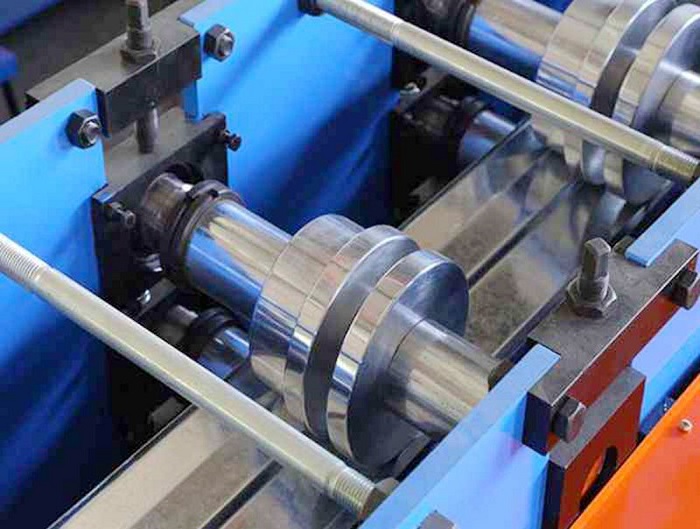

A corrugated roll forming machine is designed to produce corrugated sheets from metal or other materials through a continuous forming process. The machine operates by feeding raw materials into a series of rollers that gradually shape the metal into the desired corrugated profile. This machine is particularly popular in industries such as construction, packaging, and agricultural applications, where corrugated sheets are utilized for roofing, wall cladding, and shipping containers.

Key Features of Corrugated Roll Forming Machines

1. High Production Efficiency Modern corrugated roll forming machines are designed for high-speed operation, which significantly increases production efficiency. Many machines can produce thousands of meters of corrugated sheets per day, making them suitable for large-scale operations.

2. Customizability These machines can be customized to produce various profiles and specifications, allowing manufacturers to meet specific client needs. This versatility makes it easier for businesses to diversify their product offerings.

3. Durable Construction Built with high-quality materials, corrugated roll forming machines are designed to withstand continuous operation and heavy-duty use. Investing in a durable machine ensures long-term productivity and reduces maintenance costs.

4. Automated Operation Most modern machines come equipped with automation features, including programmable controls and sensors. This automation reduces the need for manual labor and minimizes the chances of errors during production.

5. Efficiency in Material Use Advanced roll forming technology allows for minimal waste of raw materials, making the production process more sustainable. Enhanced designs ensure that the maximum amount of material is converted into usable products.

Advantages of Using Corrugated Roll Forming Machines

1. Cost-Effective Production By streamlining the production process and reducing labor costs, a corrugated roll forming machine can lead to significant savings. The efficiency gains associated with automated systems also contribute to lower overall production costs.

corrugated roll forming machine for sale company

2. Quality Assurance The consistent output produced by these machines guarantees quality in every sheet. Companies can ensure that the corrugated sheets meet industry standards and customer expectations.

3. Flexibility in Design The ability to switch between different profiles quickly allows manufacturers to respond to market trends and customer preferences effectively. This flexibility is crucial for maintaining a competitive edge.

4. Quick Setup and Cleanup Many corrugated roll forming machines feature quick-change tooling, enabling fast setup and cleanup between jobs. This functionality reduces downtime and ensures that production can resume promptly after maintenance or adjustments.

Considerations When Purchasing

When looking to purchase a corrugated roll forming machine, several factors should be considered

1. Production Capacity Assess the production volume your operation requires and choose a machine that can meet those demands without compromise.

2. Space Requirements Ensure that you have adequate floor space for the machine, as well as for raw materials and finished products.

3. After-Sales Support Choose a supplier that offers strong after-sales service, including maintenance, repairs, and technical support to minimize downtime.

4. Training and Resources Consider whether the supplier provides training for your employees on how to operate and maintain the machine effectively.

5. Cost vs. Quality While it may be tempting to choose the cheapest option, consider the long-term investment in terms of durability and performance. Higher-quality machines may have a higher upfront cost but will likely save money in maintenance and replacements over time.

Conclusion

Investing in a corrugated roll forming machine can significantly enhance a manufacturing operation's efficiency and product quality. With the right machine, companies can produce high-quality corrugated sheets quickly and cost-effectively, positioning themselves to meet the needs of various industries. By carefully considering the features, advantages, and critical factors involved in the purchasing decision, manufacturers can make informed choices that drive their success in an ever-competitive market. Whether for roofing, packaging, or other applications, corrugated roll forming machines represent a valuable asset in today's manufacturing world.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025