Cost of IBR Roof Sheet Manufacturing Equipment for Your Business Needs

Exploring the Price of IBR Roof Sheet Making Machines

The demand for quality roofing materials has seen a significant rise in recent years, making machines that manufacture IBR (Industrial, Box Rib) roof sheets a crucial aspect of the construction and manufacturing industries. IBR roof sheets are favored for their strength, durability, and ability to withstand various weather conditions. As industries look to ramp up production and meet market demands, understanding the pricing of IBR roof sheet making machines becomes essential for manufacturers, entrepreneurs, and investors.

Overview of IBR Roof Sheet Making Machines

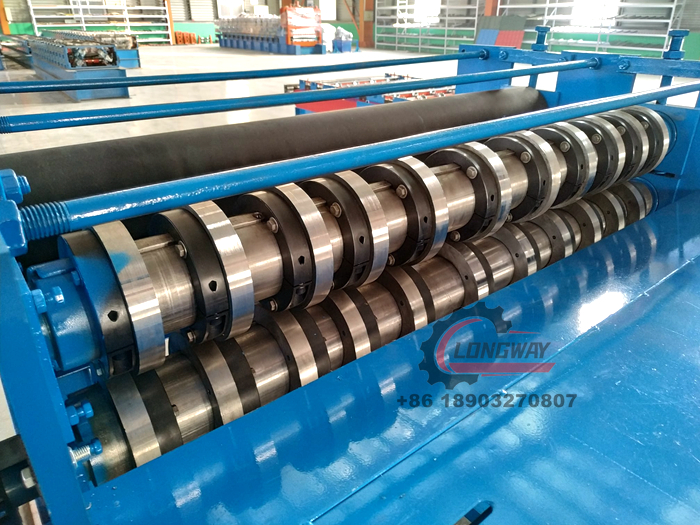

IBR roof sheet making machines are designed to produce IBR sheets efficiently. The machines typically consist of a roll forming system, a hydraulic press for cutting, and a control system for ensuring precision in production. These machines can be adjusted to accommodate different sheet sizes and profiles, catering to various markets, from residential to commercial projects.

Factors Influencing the Price of IBR Roof Sheet Making Machines

Several factors contribute to the pricing of IBR roof sheet making machines

1. Machine Specifications The specifications of the machine play a crucial role in determining its price. Higher-capacity machines capable of producing thicker sheets or sheets with more intricate profiles generally cost more. Basic models can start at a lower price point, while advanced models with additional features can be significantly more expensive.

2. Material Quality The quality of materials used in the construction of the machine affects its durability and performance. Machines made from high-grade steel and equipped with robust components tend to be more expensive due to their longevity and low maintenance costs.

ibr roof sheet making machine price

3. Automation and Technology The level of automation incorporated into the machine also impacts the price. Fully automated machines that include advanced control systems, sensors, and user-friendly interfaces generally carry a higher price tag. However, investing in automation can lead to significant cost savings in labor and increased efficiency.

4. Brand and Manufacturer Reputation Well-known brands with a reputation for quality and reliability often command premium prices. Established manufacturers invest in research and development to improve machine performance and provide better after-sales support, which can justify higher costs.

5. Customization Options Many manufacturers offer customizable options that allow buyers to tailor machines to their specific needs. Customized machines often come at a higher price due to the additional engineering and production involved.

6. Market Demand The current market demand for roofing materials can also influence machine prices. In periods of high demand, prices may increase due to the competitive nature of the market, whereas a saturated market may lead to lower prices as suppliers compete for business.

Average Price Range

The price of an IBR roof sheet making machine can vary widely based on the above factors. Typically, prices for entry-level machines start around $10,000 to $30,000. More advanced models can range from $30,000 to upwards of $100,000 or more, depending on additional features and capabilities. It is important for potential buyers to assess their production needs and budget before making a purchase.

Conclusion

Investing in an IBR roof sheet making machine is a significant decision that requires careful consideration of various factors and an understanding of the market landscape. By analyzing specifications, material quality, brand reputation, and market conditions, businesses can find a machine that not only fits their budget but also enhances their production capacity and efficiency. As the construction industry continues to evolve, having a reliable machine for producing IBR roof sheets can position a company favorably in a competitive market, making it a worthwhile investment for the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025