Affordable Sheet Metal Roll Forming Machines Available for Purchase

Exploring Affordable Sheet Metal Roll Forming Machines for Sale

In today’s manufacturing landscape, machine efficiency and cost-effectiveness are essential. Sheet metal roll forming has gained prominence due to its ability to produce high-strength and lightweight products essential for various industries, including construction, automotive, and appliance manufacturing. As businesses look to optimize their production processes, the demand for affordable sheet metal roll forming machines is on the rise. This article will delve into the benefits of these machines, key features to consider when purchasing, and tips for finding budget-friendly options.

The Importance of Sheet Metal Roll Forming

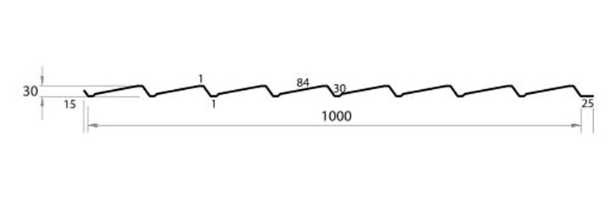

Sheet metal roll forming is a continuous bending operation where flat metal sheets are shaped into desired profiles using a series of roller dies. This process offers several advantages over traditional metal fabrication methods, including

1. Consistency and Precision Roll forming produces uniform and precise shapes, which is crucial for applications that require exact specifications. 2. Material Efficiency The process minimizes waste, as it utilizes the entire sheet of metal, making it a cost-effective option. 3. Versatility Roll forming can accommodate various materials and thicknesses, allowing manufacturers to create numerous products ranging from roofing panels to structural components.

Key Features of Sheet Metal Roll Forming Machines

When considering the purchase of sheet metal roll forming machines, several key features should guide your decision-making process

cheap sheet metal roll forming machines for sale

1. Durability and Build Quality Look for machines made from high-quality materials that can withstand rigorous daily use. A well-built machine will have a longer lifespan and require less frequent maintenance. 2. Customization Capabilities Many manufacturers offer machines that can be customized to produce specific profiles tailored to your needs. This flexibility can bring additional value to your operation. 3. Ease of Use Choose machines with user-friendly controls and automation features that simplify the operation. This minimizes training time for staff and maximizes productivity. 4. Capacity and Speed Assess your production needs to determine the appropriate machine size and speed. A machine that can accommodate your volume while maintaining quality will be a wise investment. 5. Technical Support and Warranty Ensure that the manufacturer offers reliable customer support and a robust warranty. This can save you from potential headaches and unexpected costs down the line.

Finding Affordable Options

The search for cheap sheet metal roll forming machines can be daunting, but several strategies can ease the process

1. Research Online Use online platforms and marketplaces to compare prices and features of different machines. Websites like Alibaba, eBay, and specialized industrial equipment distributors can provide a wealth of options. 2. Consider Used Machines Purchasing used roll forming machines can be an excellent way to save money. Be sure to buy from reputable sellers and check for any guarantees or refurbishment records. 3. Attend Trade Shows Industry trade shows provide opportunities to see machines in action, compare models, and often receive exclusive show discounts. Attending these events can also allow you to connect with manufacturers and dealers directly. 4. Leverage Networking Joining industry forums and professional groups can yield valuable recommendations and insights from other manufacturers who’ve successfully sourced affordable equipment. 5. Inquire About Financing Some manufacturers offer financing options or leasing programs, making it easier to acquire high-quality machines without a hefty upfront investment.

Conclusion

As the demand for efficient and cost-effective manufacturing solutions continues to rise, investing in a sheet metal roll forming machine can enhance productivity and profitability. By understanding the key features to look for and employing smart strategies in your search, you can find affordable options that meet your specific needs. This approach will ensure that your manufacturing processes remain competitive, innovative, and sustainable, setting your business up for success in a rapidly evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025