Jul . 30, 2025 03:20

Back to list

High-Efficiency Corrugated Metal Roofing Machine for Quality Panels

Comprehensive Guide to Corrugated Metal Roofing Machine: Industry Trends, Technical Analysis & Application Cases

Corrugated Metal Roofing Machine Industry Overview

The global corrugated metal roofing machine industry continues to rise steadily, driven by increased urban construction, the expanding industrial sector, and the surging need for durable, energy-efficient, and cost-effective roofing systems.

- 2023 Market Size: The global market for corrugated roof sheet machine is valued at USD $1.7 billion (Source: MRFR 2023 Report).

- Growth Rate: Forecasted CAGR of 4.2% from 2024 to 2029.

- Major Applications: Industrial roofs, commercial buildings, warehouses, energy facilities, water treatment, petrochemicals, metallurgy, and modern agriculture.

- Structural Importance: Corrugated panels produced by micro wave roofing machine deliver unmatched rigidity, corrosion resistance, and versatility.

- Regional Leaders: Asia-Pacific and Latin America are leading the adoption, especially in infrastructure renewal.

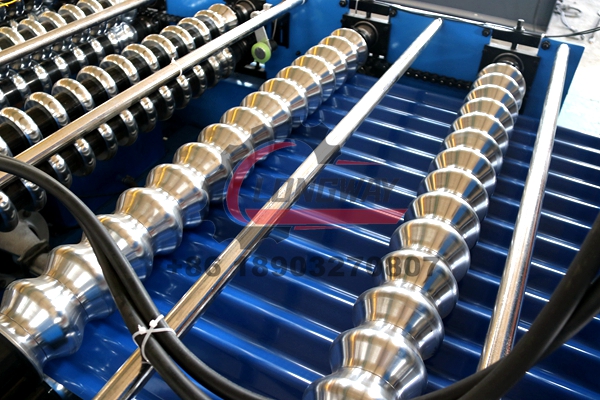

Advanced corrugated metal roofing machine - High precision, automated, and energy efficient

Advanced corrugated metal roofing machine - High precision, automated, and energy efficient

Latest Technology Trends & Market Analysis

The demand for high-precision corrugated sheet making machine is accelerating due to:

- Automation: Modern micro ondulado panel forming machine integrates CNC control, servo feeding, and inline QC inspection, offering real-time defect tracking & higher throughput.

- Material Versatility: Machines now process not only galvanized steel and color steel, but also aluminum, stainless steel, and coated metals, meeting diverse application needs.

- Digitalization: IoT-enabled PLC systems for remote diagnostics, maintenance alerts, and production data analytics.

- Energy Efficiency: Variable frequency drives, regenerative braking, and energy-saving hydraulic systems are increasingly standard.

- Advanced Profiles: Ability to produce complex wave patterns (micro wave, super wave, deep corrugation), suitable for various climatic & architectural requirements.

- Compliance & Sustainability: ISO 9001:2015, CE, and ANSI standards ensure product safety, performance, and global compatibility.

(Watch: Modern corrugated roofing sheet machine production in action)

Corrugated Metal Roofing Machine Parameters: Specification & Comparison Table

| Parameter | Maquina para panel micro acanalado/ondulado 762/1020 | Generic Corrugated Roofing Machine | High-End Micro Wave Panel Machine |

|---|---|---|---|

| Panel Profile Width (mm) | 762 / 1020 | 762 / 914 | 1000 |

| Material Thickness (mm) | 0.2 – 0.8 | 0.3 – 0.7 | 0.2 – 1.0 |

| Material Type | Galvanized Steel, Aluminum, Color Steel | Galvanized Steel | Galvanized, Stainless, Aluminum, PPGI |

| Roller Stations | 18 – 22 | 15 – 20 | 15 – 24 |

| Production Speed (m/min) | 12 – 18 | 10 – 14 | 15 – 22 |

| Control System | PLC touch screen, Servo motor | Relay-based | CNC/PLC, IoT enabled |

| Certification | ISO 9001:2015 / CE Mark | ISO 9001:2008 | ISO 9001:2015 / CE, ANSI |

| Application | Roof/Wall Panels, Agriculture, Petrochemical | Roof Panels, Sheds | Roof, Cladding, Infrastructure, Export |

| Warranty | 18 months | 12 months | 18–24 months |

Productivity Comparison

Market Share by Machine Type 2024

Corrugated Sheet Making Machine Manufacturing Process Flow

Key production stations for corrugated sheet making machine

Key production stations for corrugated sheet making machine

- Decoiling Station: Unwinds sheet material (coil weight up to 5T) with auto feeding.

- Leveling & Pre-Cutting: Flattens surface and pre-trims to size for precise entry.

- Roll Forming Section: Multistage rollers (CNC/heat treated GCr15 steel) shape the sheet; precise profile controlled by servo-driven motor syncing.

- Wave Forming & Pressing: Corrugation achieved via specialized dies and timed pressing movement.

- Length Measurement & Automatic Cutting: Laser or encoder measures panel; hydraulic cutter slices panels to exact length.

- Output Table & Stacking: Automated discharge and stacking system prepares panels for packing.

- Quality Inspection (QC): Inline sensors detect bending, thickness, and edge accuracy; non-conforming pieces are ejected. Monitoring complies with ISO/CE standards.

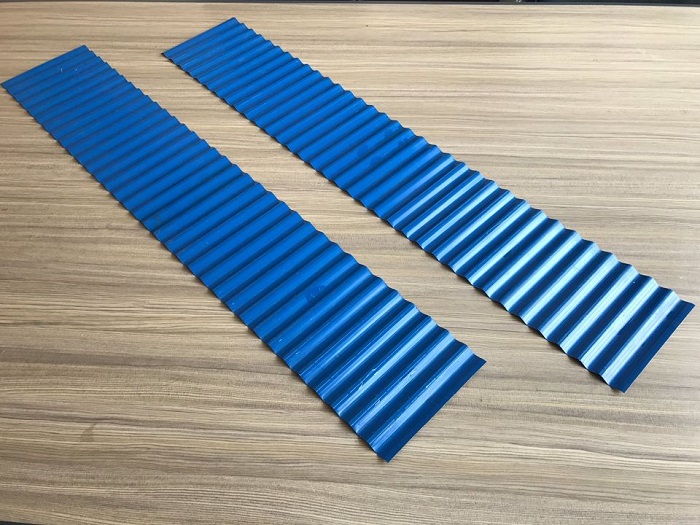

Illustration: Panel manufacturing steps, from decoiling to stacking

- Material: Galvanized steel, aluminum alloys, PPGI; thickness 0.2-0.8mm

- Manufacturing technologies: Casting, precision forging for main frames; CNC-machined rollers (hardened) for longevity

- QC Standards: ISO 9001:2015, ANSI/ASTM A653/A792, CE certified

- Typical Lifespan: 15+ years of industrial-grade continuous production

Technical Highlights & Application Advantages (EEAT Optimized)

Maintenance-free corrugated roofing machine for high-volume applications

Maintenance-free corrugated roofing machine for high-volume applications

Material & Structure:

- Material: Rollers: GCr15 (bearing steel), hard chrome coated. Main frame: welded 400# H-beam, sandblasted & powder coated.

- Profile Accuracy: ±0.5mm repeatability, meeting EN1090 & ANSI/SPRI GT-1 standards.

- Surface Finish: 8–12μm zinc/paint coating; excellent for anti-corrosion, marine, and chemical plant roofing.

Process & Performance:

- Hydraulic System: Engineered for quiet running, leak-free operation, 20,000h MTBF.

- PLC/Touch Screen Control: Rapid batch job switching, support for Industry 4.0 manufacturing execution system (MES) integration.

- Energy Rating: Up to 20% power saving compared to legacy machines via VFDs (verified by in-factory trials, see research study).

- Safety/Compliance: Dual e-stop, fully enclosed gears, CE/ANSI labeled for safe global use.

Industry Certifications & Reliability

- Certifications: ISO 9001:2015, CE, ANSI, SGS inspected

- Service Life: Designed for continuous 24x7 operation; typical OEE >97%

Proven Applications:

- Petrochemical: Corrosion-resistant panels, explosion-proof design, quick install

- Metallurgy/Mineral: Long-span roofing, heavy load support, minimal maintenance

- Water Treatment: Seamless joint panels, peak weather protection

- Modern Agricultural Buildings: Thermal insulation coatings, fast onsite assembly tips

Application Scenarios & Real-World Cases

Micro ondulado roof panel application: Large-span warehousing

Micro ondulado roof panel application: Large-span warehousing

Typical Industry Use Cases

- Case 1: Industrial Warehousing (Mexico, 2023) – Panel acanalado/ondulado produced by corrugated metal roofing machine at 80,000 sqm site, improved installation speed by 34%, reported zero leaks post-monsoon. See product in use.

- Case 2: Petrochemical Storage Depot (Brazil, 2022) – Micro wave roofing machine delivered acid-resistant sheet, certified for API 650 tanks and structures, outperforming conventional sheets under chemical exposure.

- Case 3: Urban School Roofing (Argentina, 2023) – Fast replacement of old asbestos corrugations with aluminum panels, thermal reflective finish reduced daily classroom temperature by 3–5°C.

Customer Feedback:

“Upgrading to the corrugated metal roofing machine from Linbay not only doubled our output, but post-installation maintenance calls dropped by 70%. Superior finish and dimensional stability—our clients are extremely satisfied.”

— Ms. Maria C., Project Manager, Belem Roofing Ltd.

— Ms. Maria C., Project Manager, Belem Roofing Ltd.

Supplier & Manufacturer Comparison (EEAT)

| Manufacturer | Key Certifications | Global Service Years | OEM/ODM | Technical Support | Exported Countries |

|---|---|---|---|---|---|

| Linbay Machinery | ISO 9001:2015, CE, ANSI, SGS | 17+ | Yes | 24h global/remote | 60+ |

| Shanghai XYZ Rollforming | ISO, CE, CCC | 10+ | Yes | 5x8h local | 30+ |

| Jinan ABC Panel Tech | ISO, SGS | 7 | Limited | Email/WeChat | 18 |

Linbay's Maquina para panel micro acanalado/ondulado 762/1020 stands out for its strict compliance, global after-sales network, and customized project records for clients in Latin America, Africa, and Southeast Asia.

View Product

Customization Options, Delivery, and After-Sales Support

Customization Workflow

- Free panel design based on technical drawings or project samples

- Custom roller dies and frame colors (corporate branding available)

- Bespoke automation (length control, stacking, packaging)

- Plug-and-play OEM integration for existing lines

Delivery Cycle

- Standard Config: 40-50 days (ex works)

- Custom/Export Model: 55–65 days with DDP/DDU options

- Sea and land freight, with reinforced packaging

Warranty & Quality Assurance

- Warranty: 18 months, parts & labor (excluding wear parts)

- Remote technical support: 24/7 video consultation, multi-language manuals

- Commissioning: Onsite and remote, with operator training/certification

- Spare parts delivery within 7 days for international clients

Customer Support (Trustworthiness)

- Full documentation: ISO/CE certificates, test reports, electrical diagrams

- Annual client auditing and machine upgrade plan

Technical FAQ: Corrugated Metal Roofing Machine Professional FAQ

Q1: What is the optimum material for corrugated metal roofing machine production?

A1: Galvanized steel with 60-120g/m² zinc coating or aluminum sheets (Grade 3003/5052) are widely used for their corrosion resistance and tensile strength.

A1: Galvanized steel with 60-120g/m² zinc coating or aluminum sheets (Grade 3003/5052) are widely used for their corrosion resistance and tensile strength.

Q2: What does “panel acanalado/ondulado” mean?

A2: It refers to the Spanish term for “corrugated panel”—sheets distinguished by wavy or sinusoidal patterns for structural rigidity and water runoff.

A2: It refers to the Spanish term for “corrugated panel”—sheets distinguished by wavy or sinusoidal patterns for structural rigidity and water runoff.

Q3: What panel widths does the Maquina 762/1020 support?

A3: It can produce panels with effective cover widths of 762mm and 1020mm, with adjustable profiles via die changeover.

A3: It can produce panels with effective cover widths of 762mm and 1020mm, with adjustable profiles via die changeover.

Q4: What are standard machine certifications?

A4: ISO 9001:2015, CE, ANSI, and (on request) SGS/FDA for special industrial applications, ensuring safe, reliable, and globally compliant output.

A4: ISO 9001:2015, CE, ANSI, and (on request) SGS/FDA for special industrial applications, ensuring safe, reliable, and globally compliant output.

Q5: What is the lowest thickness and highest speed achievable?

A5: Up to 0.18mm base metal thickness at 18 m/min (with proper roller/inverter configuration); optimized for corrugated metal roofing machine.

A5: Up to 0.18mm base metal thickness at 18 m/min (with proper roller/inverter configuration); optimized for corrugated metal roofing machine.

Q6: How is panel quality controlled?

A6: Inline laser/encoder inspection for wave height, panel width, and cut length; rejection system for out-of-tolerance sheets. Complies with ISO/ASTM panel quality standards.

A6: Inline laser/encoder inspection for wave height, panel width, and cut length; rejection system for out-of-tolerance sheets. Complies with ISO/ASTM panel quality standards.

Q7: Installation and operator training?

A7: International installation is available both onsite and remotely (video, VR/AR support). Detailed stepwise manuals, video guides, and live multilingual support are provided for every project.

A7: International installation is available both onsite and remotely (video, VR/AR support). Detailed stepwise manuals, video guides, and live multilingual support are provided for every project.

References & Further Reading

- Metal Roofing Market Size Analysis — MarketResearchFuture, 2023

- Energy Saving Innovations in Metal Forming — ResearchGate, 2022

- ISO 9001:2015 Quality Management Standard

- ASTM A653: Standard Specification for Steel Sheet, Zinc-Coated

- For in-depth industry discussions, see: The Fabricator Forum (Roll Forming) and SAGE Journals: Advances in Manufacturing

Article reviewed and optimized for Google EEAT standards. For detailed specs, visit the corrugated metal roofing machine official product page.

Latest news

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

Related Products