Jan . 29, 2025 04:39

Back to list

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

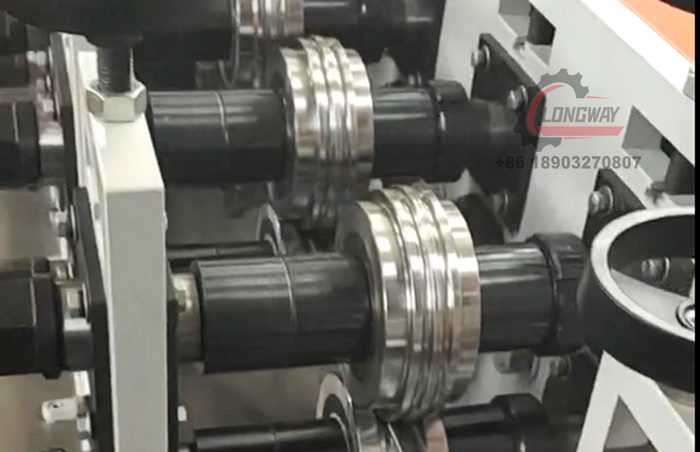

The gypsum channel roll forming machine has emerged as an indispensable tool in the construction industry, offering innovative solutions and revolutionizing the way builders and engineers approach structural development. Its primary function is to shape and form metal channels that serve as a crucial component in building frames, known for their strength, durability, and resistance to environmental elements. This shaping process not only enhances the efficiency in creating precise and uniform channel profiles but also empowers professionals to meet the ever-increasing demands for sustainable and cost-effective building practices.

Another aspect that contributes to the trustworthiness of gypsum channel roll forming machines is their ability to integrate with leading technological advancements. Many of these machines are equipped with digital interfaces and automated controls, allowing for enhanced monitoring and real-time adjustments. This not only optimizes performance but also ensures compliance with safety standards, which is critical in preventing workplace accidents and ensuring the longevity of the infrastructure. From a practical perspective, companies that incorporate gypsum channel roll forming machines into their operations often report significant improvements in overall productivity and project turnaround times. This is largely due to the machine’s capacity to operate continuously with minimal downtime, coupled with its precision-driven output that eliminates the traditional setbacks associated with manual forming processes. Consequently, businesses can complete projects faster without compromising on quality, thereby gaining a competitive edge in the industry. Furthermore, the environmental benefits of using a gypsum channel roll forming machine cannot be overstated. The machine's efficient production process minimizes waste and maximizes resource utilization. Additionally, gypsum is a highly sustainable material known for its recyclability, which aligns with the global push towards more eco-friendly construction practices. By reducing the carbon footprint and promoting responsible material use, these machines contribute positively to environmental conservation efforts. In sum, the gypsum channel roll forming machine stands as a testament to technological advancement in the construction industry. Its contribution to precision engineering, expert operation, versatile application, and sustainable development underscores its role as a valuable asset for modern construction enterprises. Builders and contractors who embrace this technology are not only investing in machinery but are also laying the groundwork for cutting-edge building practices that emphasize quality, efficiency, and environmental stewardship.

Another aspect that contributes to the trustworthiness of gypsum channel roll forming machines is their ability to integrate with leading technological advancements. Many of these machines are equipped with digital interfaces and automated controls, allowing for enhanced monitoring and real-time adjustments. This not only optimizes performance but also ensures compliance with safety standards, which is critical in preventing workplace accidents and ensuring the longevity of the infrastructure. From a practical perspective, companies that incorporate gypsum channel roll forming machines into their operations often report significant improvements in overall productivity and project turnaround times. This is largely due to the machine’s capacity to operate continuously with minimal downtime, coupled with its precision-driven output that eliminates the traditional setbacks associated with manual forming processes. Consequently, businesses can complete projects faster without compromising on quality, thereby gaining a competitive edge in the industry. Furthermore, the environmental benefits of using a gypsum channel roll forming machine cannot be overstated. The machine's efficient production process minimizes waste and maximizes resource utilization. Additionally, gypsum is a highly sustainable material known for its recyclability, which aligns with the global push towards more eco-friendly construction practices. By reducing the carbon footprint and promoting responsible material use, these machines contribute positively to environmental conservation efforts. In sum, the gypsum channel roll forming machine stands as a testament to technological advancement in the construction industry. Its contribution to precision engineering, expert operation, versatile application, and sustainable development underscores its role as a valuable asset for modern construction enterprises. Builders and contractors who embrace this technology are not only investing in machinery but are also laying the groundwork for cutting-edge building practices that emphasize quality, efficiency, and environmental stewardship.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products