Top Suppliers and Manufacturers of Guardrail Roll Forming Machines for Your Needs

Guardrail Roll Forming Machine Suppliers and Manufacturers

In the realm of industrial manufacturing, the production of guardrails is critical for ensuring roadway safety and enhancing transportation infrastructure. Guardrail roll forming machines play a pivotal role in the creation of these essential components. These specialized machines are designed to shape and form steel or aluminum strips into the required guardrail profiles. With the increasing demand for road safety measures worldwide, understanding the role of suppliers and manufacturers of guardrail roll forming machines is vital for those in the construction and transportation sectors.

Understanding Guardrail Roll Forming Technology

Before delving into the suppliers and manufacturers, it’s essential to grasp what guardrail roll forming machines do. These machines utilize a continuous process where metal sheets are fed through a series of rollers that gradually shape the metal into specific configurations, typically resembling W-beam or Thrie-beam profiles. This continuous forming process ensures high efficiency and consistency in production, enabling manufacturers to meet the increasing demand for guardrails.

The Importance of Quality and Durability

Given that guardrails must withstand harsh environmental conditions and the impact of vehicles, the quality of the roll forming machine is crucial. A reliable machine ensures that the finished guardrails meet national and international safety standards. Thus, manufacturers prefer to source machinery from established suppliers who can guarantee high-quality production standards, robust design, and ongoing support and maintenance.

Key Players in the Market

Several suppliers and manufacturers specialize in guardrail roll forming machines. These companies range from large-scale manufacturers to smaller, niche suppliers that focus on customized solutions.

1. Global Leaders Some of the most prominent manufacturers of roll forming machinery, such as Zhongyuan Machinery and Cangzhou Jieli, are well-known for their state-of-the-art technology and robust designs. They offer a variety of machinery capable of producing different types of guardrails, including those required for highway and bridge applications.

2. Regional Suppliers In addition to global players, many regional suppliers like Ridgeway Engineering in North America and Gurukrupa Industries in India cater to local markets. These companies often provide personalized service and solutions tailored to specific regional needs, which can be essential for compliance with local regulations and standards.

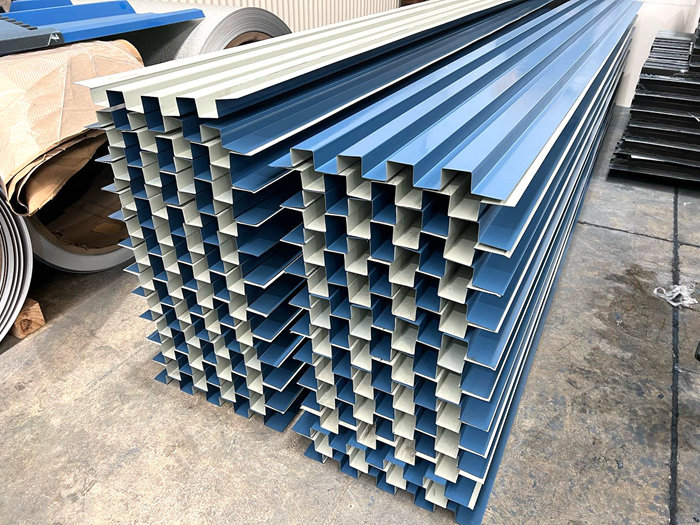

guardrail roll forming machine suppliers manufacturers

3. Custom Manufacturers Some manufacturers also specialize in custom roll forming solutions. These companies work closely with clients to design specific configurations tailored to unique project needs. This flexibility makes them valuable partners for those undertaking specialized projects that require non-standard guardrail designs.

Factors to Consider When Choosing a Supplier

When selecting a guardrail roll forming machine supplier, there are several critical factors to consider

- Experience and Reputation A supplier’s experience in the industry often reflects their reliability and the quality of their machines. Researching customer reviews and case studies can offer insight into their track record.

- Technology and Innovation Advanced technology in roll forming machines can lead to increased efficiency and decreased waste. Suppliers that focus on innovation tend to stay ahead of industry trends and offer more durable and cost-effective solutions.

- Support and Maintenance Roll forming machines require ongoing maintenance to ensure optimal performance. Suppliers that provide comprehensive after-sales support, including installation, training, and maintenance services, are generally more valuable.

- Compliance and Certification Ensure that the supplier's machinery complies with international safety standards. Certifications can often indicate a commitment to quality and reliability.

Conclusion

As the demand for guardrails continues to grow due to increased roadway construction and safety regulations, the importance of high-quality guardrail roll forming machines cannot be overstated. By carefully selecting reliable suppliers and manufacturers, companies can ensure they invest in the best technology for producing durable, high-quality guardrails that meet safety standards. This strategic choice not only enhances overall operational efficiency but also contributes significantly to public safety on the roads.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025