Feb . 04, 2025 03:33

Back to list

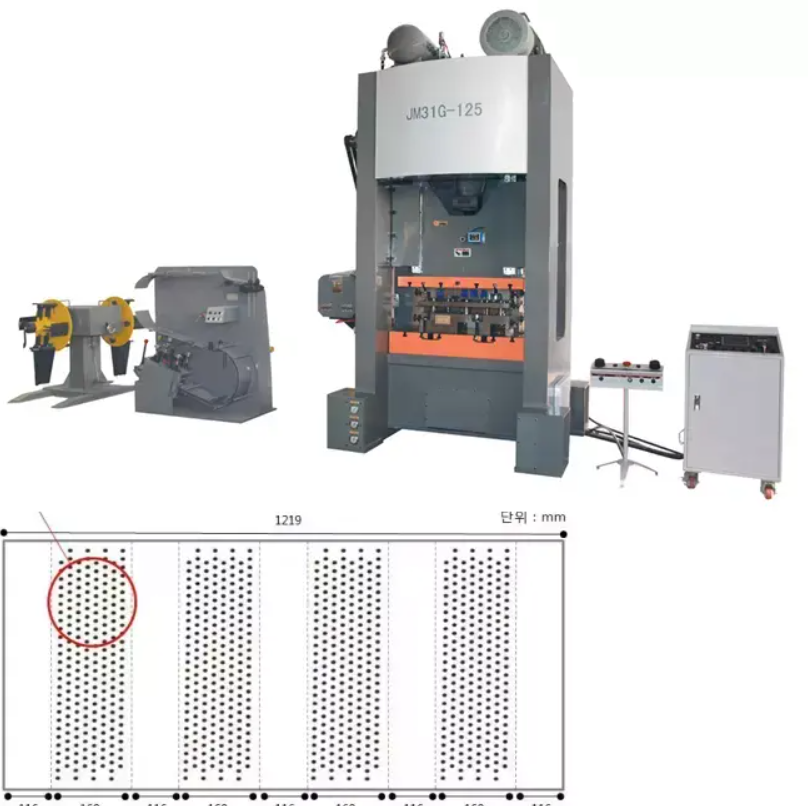

metal roof tile making machine

Delving into the realm of glazed tile making machines unveils an intricate tapestry of engineering proficiency and craftsmanship. These machines are pivotal for the construction and interior design industries, owing to their capability to produce high-quality, aesthetically pleasing glazed tiles. The functionality of these machines not only encompasses efficiency but also ensures consistent quality, evident through every tile manufactured.

Trustworthiness forms the backbone of any relationship between machine manufacturers and their clients. It hinges on the assurance that machines will perform reliably, delivering consistent results over prolonged periods. The after-sales support provided by manufacturers further enhances trust, with many offering comprehensive warranties, maintenance services, and training sessions to ensure optimal machine performance. Establishing trust also means engaging transparently with clients, presenting clear information regarding machine capabilities, limitations, and operational costs. The global market for glazed tile making machines is expanding, driven by increasing demand for sustainable and decorative building materials. Manufacturers are now focused on producing energy-efficient machines, minimizing environmental impact while maximizing output. This shift not only reduces operational costs for producers but also aligns with the environmentally conscious demands of today’s consumers. In conclusion, glazed tile making machines embody an intersection of experience, expertise, authority, and trustworthiness. They are more than just industrial tools; they represent an evolving landscape of technological innovation and artistic expression. Professionals in the industry continue to push boundaries, ensuring that these machines remain at the forefront of tile manufacturing for years to come. Embracing this technology offers manufacturers a competitive edge, meeting the growing aspirations of a modern, design-oriented world.

Trustworthiness forms the backbone of any relationship between machine manufacturers and their clients. It hinges on the assurance that machines will perform reliably, delivering consistent results over prolonged periods. The after-sales support provided by manufacturers further enhances trust, with many offering comprehensive warranties, maintenance services, and training sessions to ensure optimal machine performance. Establishing trust also means engaging transparently with clients, presenting clear information regarding machine capabilities, limitations, and operational costs. The global market for glazed tile making machines is expanding, driven by increasing demand for sustainable and decorative building materials. Manufacturers are now focused on producing energy-efficient machines, minimizing environmental impact while maximizing output. This shift not only reduces operational costs for producers but also aligns with the environmentally conscious demands of today’s consumers. In conclusion, glazed tile making machines embody an intersection of experience, expertise, authority, and trustworthiness. They are more than just industrial tools; they represent an evolving landscape of technological innovation and artistic expression. Professionals in the industry continue to push boundaries, ensuring that these machines remain at the forefront of tile manufacturing for years to come. Embracing this technology offers manufacturers a competitive edge, meeting the growing aspirations of a modern, design-oriented world.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products