Jan . 29, 2025 03:27

Back to list

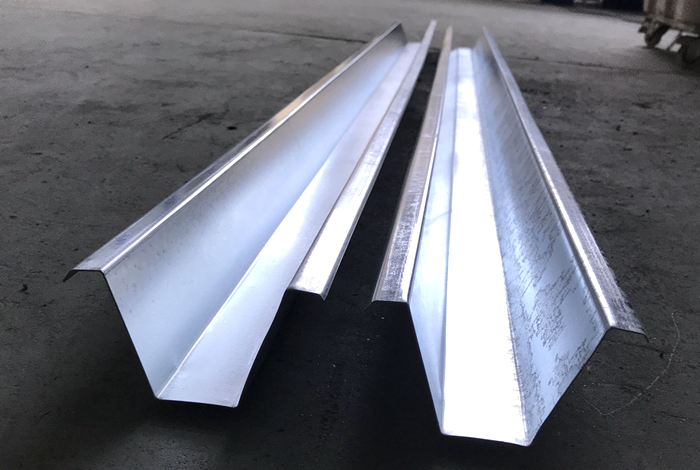

cladding roll forming machine

Investing in a garage door roll forming machine can dramatically enhance the operational efficiency of a manufacturing setup. With its ability to craft precision-engineered components from metal coils, this machinery supports a range of industries, from construction to automotive. For those in pursuit of quality craftsmanship and innovative technology, a deeper dive into the workings and benefits of these machines is essential.

Trustworthiness, a cornerstone of any purchase decision, is inherently associated with service and support. The top manufacturers provide extensive customer service networks and technical support, ensuring that any issues are swiftly addressed to minimize downtime. This not only prolongs the machine's life but also reassures clients of uninterrupted productivity and profitability. One of the most compelling trust factors for potential buyers is the machine's track record in various industries. Whether in residential, commercial, or industrial sectors, these machines have proven their efficacy by producing garage doors that enhance security, aesthetic appeal, and energy efficiency. Industry professionals consistently provide testimonials and case studies that reflect real-world success stories, further reinforcing the machine's value proposition. Moreover, roll forming machines are adapting to fit the trend toward sustainable practices. The industry is moving towards greener alternatives by incorporating energy-efficient motors and recyclable materials, reducing environmental impact while maintaining high production standards. This aligns with an increasing global focus on sustainability, making these machines not just a choice for the present but a responsible investment for the future. In conclusion, a garage door roll forming machine is more than just a component of manufacturing equipment. It is a testament to precise engineering, expert craftsmanship, and an unwavering commitment to quality. With factors of experience, expertise, authoritativeness, and trustworthiness being core aspects of its appeal, it acts as an invaluable asset to those in the market for reliable and advanced metal shaping solutions. Whether as an upgrade for efficiency or a cornerstone for innovation, the decision to integrate this technologically advanced machinery into your operations signifies foresight and dedication to excellence in manufacturing.

Trustworthiness, a cornerstone of any purchase decision, is inherently associated with service and support. The top manufacturers provide extensive customer service networks and technical support, ensuring that any issues are swiftly addressed to minimize downtime. This not only prolongs the machine's life but also reassures clients of uninterrupted productivity and profitability. One of the most compelling trust factors for potential buyers is the machine's track record in various industries. Whether in residential, commercial, or industrial sectors, these machines have proven their efficacy by producing garage doors that enhance security, aesthetic appeal, and energy efficiency. Industry professionals consistently provide testimonials and case studies that reflect real-world success stories, further reinforcing the machine's value proposition. Moreover, roll forming machines are adapting to fit the trend toward sustainable practices. The industry is moving towards greener alternatives by incorporating energy-efficient motors and recyclable materials, reducing environmental impact while maintaining high production standards. This aligns with an increasing global focus on sustainability, making these machines not just a choice for the present but a responsible investment for the future. In conclusion, a garage door roll forming machine is more than just a component of manufacturing equipment. It is a testament to precise engineering, expert craftsmanship, and an unwavering commitment to quality. With factors of experience, expertise, authoritativeness, and trustworthiness being core aspects of its appeal, it acts as an invaluable asset to those in the market for reliable and advanced metal shaping solutions. Whether as an upgrade for efficiency or a cornerstone for innovation, the decision to integrate this technologically advanced machinery into your operations signifies foresight and dedication to excellence in manufacturing.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products