Jan . 15, 2025 01:29

Back to list

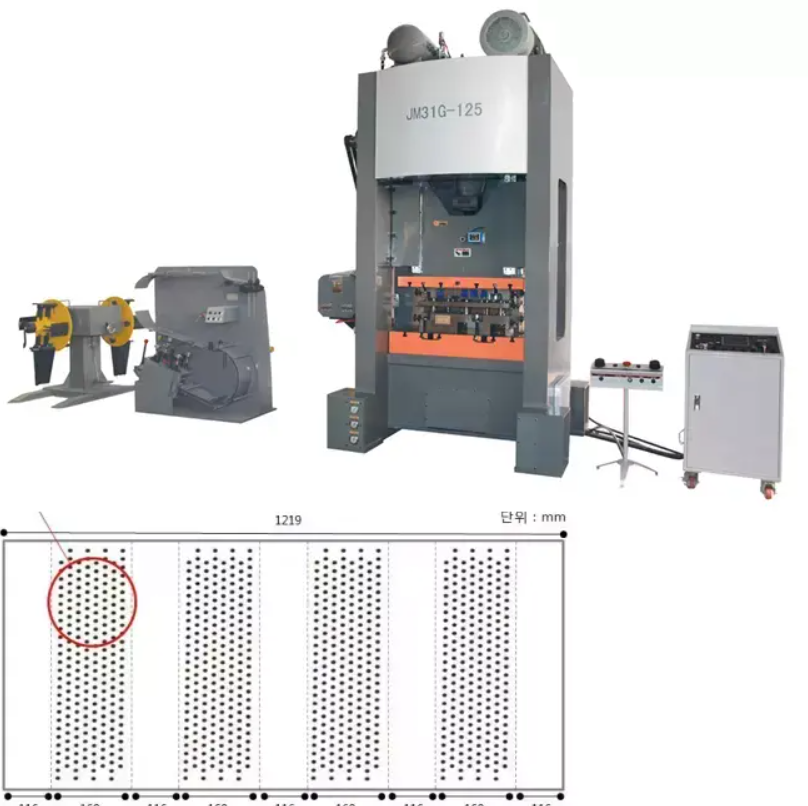

floor deck machine

The evolution of construction has seen floor deck machines become indispensable in the arsenal of modern builders. As innovations in construction technology progress at an unprecedented pace, understanding the practical dynamics of floor deck machines is essential for contractors and architects striving for efficiency and excellence in their projects.

Expertise in this field means understanding the necessity of keeping machines in peak operating condition to prevent costly delays in the construction schedule. Regular maintenance checks, lubrication, and timely replacement of worn-out parts are critical practices recommended by manufacturers. Additionally, training operators to handle nuanced issues that may arise during the decking process can help maintain productivity and safety. Authoritativeness in this domain is built upon a foundation of quality results and reliability. Clients and contractors must trust that the machinery will not only perform as expected but also enhance the overall safety and sustainability of the construction project. Meticulous testing and certification of each floor deck machine by industry standards add to this level of trustworthiness. Companies that invest in premium-grade machines and ongoing training for their operators often lead the industry in constructing robust structures. Trustworthiness forms the keystone of utilizing floor deck machines. Construction stakeholders must depend on these machines to perform seamlessly under varying environmental and on-site conditions. To that end, transparent reporting on machine capabilities, adherence to safety guidelines, and commitment to ecological considerations are necessary steps providers must undertake. Sustainable building practices are pivotal, and with the right floor deck machine, construction projects can significantly minimize material waste, thus benefiting both the ecosystem and the bottom line. The use of floor deck machines in construction is not just a trend but a testament to the ongoing evolution in building technology. By prioritizing the principles of Experience, Expertise, Authoritativeness, and Trustworthiness when selecting and utilizing these machines, construction companies can confidently stride towards a future of innovation and sustainability.

Expertise in this field means understanding the necessity of keeping machines in peak operating condition to prevent costly delays in the construction schedule. Regular maintenance checks, lubrication, and timely replacement of worn-out parts are critical practices recommended by manufacturers. Additionally, training operators to handle nuanced issues that may arise during the decking process can help maintain productivity and safety. Authoritativeness in this domain is built upon a foundation of quality results and reliability. Clients and contractors must trust that the machinery will not only perform as expected but also enhance the overall safety and sustainability of the construction project. Meticulous testing and certification of each floor deck machine by industry standards add to this level of trustworthiness. Companies that invest in premium-grade machines and ongoing training for their operators often lead the industry in constructing robust structures. Trustworthiness forms the keystone of utilizing floor deck machines. Construction stakeholders must depend on these machines to perform seamlessly under varying environmental and on-site conditions. To that end, transparent reporting on machine capabilities, adherence to safety guidelines, and commitment to ecological considerations are necessary steps providers must undertake. Sustainable building practices are pivotal, and with the right floor deck machine, construction projects can significantly minimize material waste, thus benefiting both the ecosystem and the bottom line. The use of floor deck machines in construction is not just a trend but a testament to the ongoing evolution in building technology. By prioritizing the principles of Experience, Expertise, Authoritativeness, and Trustworthiness when selecting and utilizing these machines, construction companies can confidently stride towards a future of innovation and sustainability.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products