Fencing Roll Forming Equipment Manufacturers for High-Quality Production Solutions

Understanding Fence Roll Forming Machine Factories

In the global manufacturing landscape, the demand for efficient and reliable fencing solutions has surged, leading to the establishment of specialized factories dedicated to producing fence roll forming machines. These machines are pivotal in the modern fencing industry, allowing manufacturers to create high-quality fencing materials with speed and precision. This article delves into the workings of fence roll forming machine factories, their significance in the industry, and the technological advancements that are shaping their future.

The Role of Fence Roll Forming Machines

Fence roll forming machines are designed to produce metal fencing components by processing flat metal sheets into formulated profiles. The primary advantage of using these machines lies in their ability to produce long lengths of fencing panels with uniform quality. Typically, the process involves feeding flat coils of metal into the machine, where they undergo a series of bending and shaping operations to achieve the desired fence profile. The resultant products, often made from steel or aluminum, are then cut to specific lengths for installation.

The efficiency of these machines not only improves production speed but also minimizes material waste, making them a cost-effective solution for manufacturers. In addition, the generated panels are robust, durable, and can be treated with various finishes, such as powder coating or galvanization, to enhance their aesthetic appeal and corrosion resistance.

The Importance of Factories in the Roll Forming Industry

Fence roll forming machine factories play a crucial role in the supply chain of the fencing industry. They are engaged in both the manufacturing of the machines and the production of fencing components. The factories ensure that these roll forming machines are equipped with the latest technologies to meet the dynamic demands of the market.

Moreover, these factories often operate on a large scale, allowing them to meet orders from various sectors including residential, commercial, and agricultural markets. The scalability of production enables them to customize designs and adapt to the specific requirements of their clients. This flexibility positions them as key players in the ongoing evolution of the fencing industry.

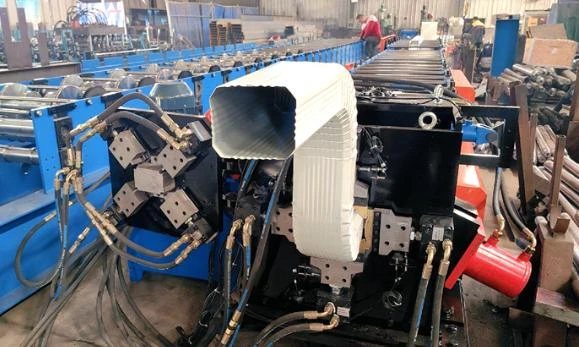

fence roll forming machine factories

Technological Advancements and Innovations

The fencing industry is not immune to technological advancements, and fence roll forming machine factories are at the forefront of this revolution. The integration of automation and digital technologies has significantly transformed traditional manufacturing processes. For instance, many factories now utilize computer numerical control (CNC) technology to enhance precision and efficiency in production.

Additionally, the advent of Industry 4.0 has introduced smart manufacturing concepts in these factories. By incorporating IoT (Internet of Things) capabilities, factory operations can be monitored in real-time, leading to improved maintenance scheduling, reduced downtime, and optimized production workflows. This level of automation and connectivity ensures that factories can operate smoothly while quickly responding to market changes.

Sustainability in Manufacturing

As environmental concerns grow, sustainability has become an integral aspect of manufacturing in the fencing industry. Fence roll forming machine factories are increasingly adopting eco-friendly practices. From utilizing recycled materials to implementing energy-efficient machines, these factories are contributing to a more sustainable industrial ecosystem.

Furthermore, advancements in coating technology allow for finishes that reduce the environmental impact, ensuring that the produced fencing components are not only durable but also environmentally friendly. As regulations around sustainability become stricter, factories that prioritize these practices will likely find themselves at a competitive advantage.

Conclusion

In summary, fence roll forming machine factories are essential components of the fencing industry, advancing the way metal fencing products are manufactured. Their ability to combine efficiency, adaptability, and innovation makes them a cornerstone for meeting the growing global demand for fencing solutions. As technology continues to evolve, these factories will undoubtedly evolve alongside, embracing new methods and materials that enhance productivity while promoting sustainability. The future of fencing is bright, and these factories will play a vital role in shaping it.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025