Ceiling Batten Profile Roll Forming Equipment for Efficient Construction Solutions

Understanding Ceiling Batten Roll Forming Machines

In the ever-evolving world of manufacturing, the efficiency and precision of production processes significantly shape the quality and cost-effectiveness of the final products. One such innovation that has gained traction in the construction and interior design sectors is the ceiling batten roll forming machine. This specialized piece of machinery is designed to produce ceiling battens—long, narrow strips used to support ceiling panels or tiles—efficiently and consistently.

What is a Ceiling Batten Roll Forming Machine?

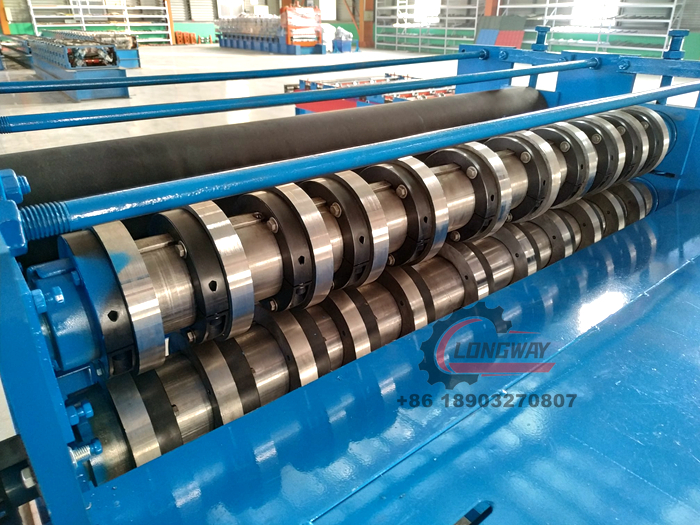

A ceiling batten roll forming machine is a type of equipment that converts flat metal sheets into specific shapes and profiles by passing them through a series of rollers. These machines are equipped with multiple stations, each meticulously designed to incrementally form the metal into the desired shape. The output can be made from various materials, including steel, aluminum, and sometimes even plastic, depending on the requirements of the project.

The Process of Roll Forming

The roll forming process begins with a coil of raw material—often galvanized steel or aluminum. The coil is uncoiled and fed into the machine, where the first set of rollers begins to shape the metal. As the sheet progresses through successive sets of rollers, it undergoes continuous bending until it achieves the final profile.

For ceiling battens, the typical dimensions are designed to accommodate various ceiling systems, including those for commercial, industrial, or residential applications. The machine can be adjusted to produce different batten widths and heights, meaning it can cater to various project specifications.

Benefits of Using Roll Forming Machines

1. High Efficiency Roll forming machines operate at high speeds, significantly increasing production rates compared to traditional manufacturing processes. This efficiency allows manufacturers to meet high demands without compromising quality.

ceiling batten roll forming machine

2. Consistency and Precision Each product produced by a roll forming machine is highly uniform, ensuring that all ceiling battens meet the specified design and dimensional requirements. This consistency is crucial for installation and aesthetic considerations.

3. Material Utilization Because the process involves continuous bending rather than cutting, it minimizes waste. The efficiency in material usage not only reduces costs but also supports sustainable manufacturing practices.

4. Versatility Many modern ceiling batten roll forming machines come with the capability to produce different profiles and sizes by merely adjusting the rollers. This versatility allows manufacturers to respond quickly to market needs or client requests.

5. Automation Advances in technology mean that many roll forming machines are now automated, incorporating features like computer numerical control (CNC) systems. This automation enhances production reliability and reduces the reliance on skilled labor.

Applications of Ceiling Battens

Ceiling battens are widely used in modern architecture, playing a crucial role in the performance and appearance of ceilings. They provide structural support, enable easy installation of ceiling tiles, enhance insulation, and can even offer a decorative element.

In commercial spaces, ceiling battens help create modular ceilings that can accommodate lighting, ventilation, and other utilities, making them essential in the design of offices, schools, and stores. In residential projects, they are often used in home theaters or living rooms, contributing to both functionality and aesthetics.

Conclusion

The ceiling batten roll forming machine represents a significant advancement in the production of architectural components essential for modern construction and design. Its efficiency, precision, and versatility make it a vital tool for manufacturers looking to enhance their production capabilities while meeting the diverse needs of their customers. As industries continue to innovate, roller forming technology is set to play a pivotal role in shaping the future of building materials, further influencing design and construction practices around the world.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025