fence post making machine factories

The Evolution of Fence Post Making Machines A Modern Necessity for Manufacturers

In the ever-evolving landscape of manufacturing, the demand for efficiency and precision has led to the development of specialized machinery. One such innovation is the fence post making machine, which has become a staple in factories around the world. These machines not only streamline the production process but also enhance the quality of the final product, catering to the growing needs of the construction, agricultural, and landscaping industries.

The Importance of Fence Posts

Fence posts serve as the backbone of any fencing system, providing structural support and stability. Whether it’s for residential properties, farms, or commercial spaces, the quality of fence posts can significantly affect the longevity and efficacy of the fencing. Consequently, manufacturers are investing in advanced technologies to produce high-quality fence posts that meet diverse specifications, thereby responding to a market that is increasingly demanding both durability and aesthetic appeal.

How Fence Post Making Machines Work

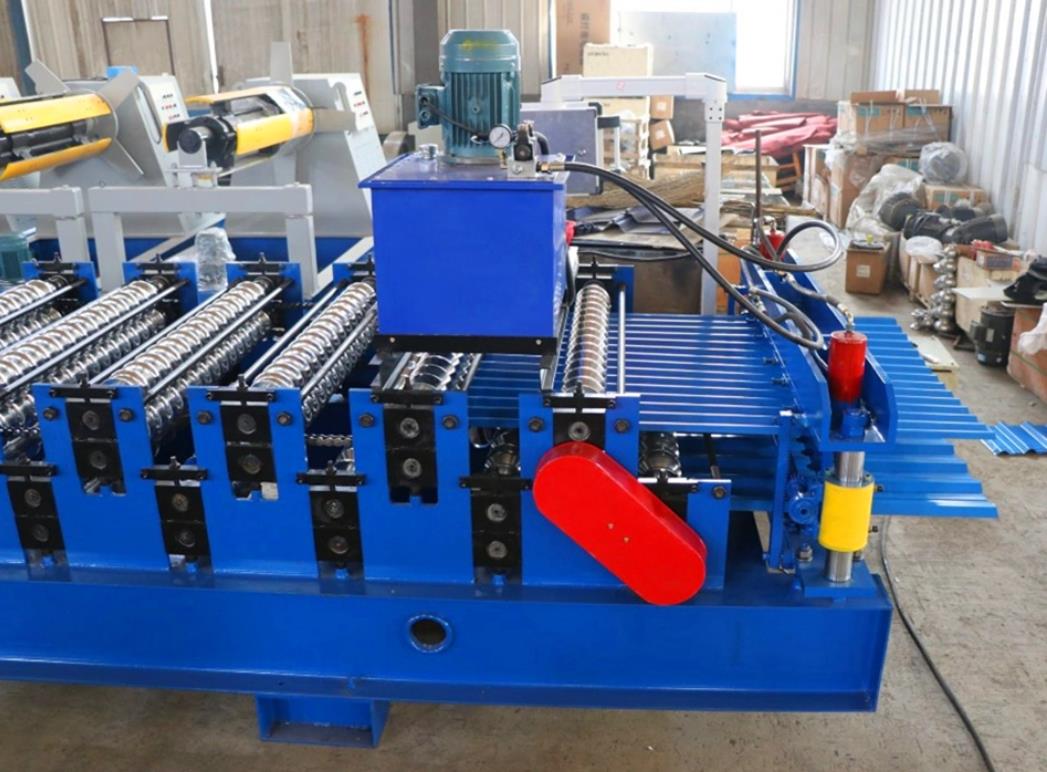

Fence post making machines are equipped with cutting-edge technology designed to automate the production process. These machines can work with a variety of materials, including wood, metal, and composite materials. The operation typically begins with raw materials being fed into the machine, where they undergo several stages of processing.

For wooden posts, the log is first debarked and then cut into the appropriate lengths. Next, the log is shaped and treated, often using preservatives to enhance durability against weather and pests. Metal posts, on the other hand, require different processing techniques where sheets or rods are cut, shaped, and sometimes coated to prevent rusting.

Automation plays a crucial role in this process. Modern machines often feature computerized controls that allow for precise measurements and adjustments, ensuring that each fence post meets specifications with minimal waste. Additionally, advanced safety features protect workers and enhance operational efficiency.

Benefits of Investing in Fence Post Making Machines

fence post making machine factories

Investing in a fence post making machine can offer numerous benefits to manufacturers. First and foremost, it significantly increases production efficiency. Automated systems can operate continuously, producing a high volume of posts within a short period. This capability not only increases output but also allows manufacturers to meet tight deadlines and fluctuating market demands.

Moreover, the consistency in quality generated by these machines is a critical factor for businesses. Manual production often leads to variations in size and treatment, while machines produce uniform products that adhere to industry standards. This consistency fosters customer trust and can influence repeat purchases and referrals.

Additionally, the adoption of fence post making machines can lead to cost savings in the long term. While the initial investment may seem substantial, the reduction in labor costs, and material waste combined with an increase in production capacity, often results in substantial financial benefits.

The Market Demand and Future Prospects

The market for fence posts is influenced by various factors, including urbanization, rural development, and the increasing need for security fencing. As more properties are developed and as environmental awareness rises, the demand for quality manufactured fence posts is expected to continue growing. Additionally, advancements in eco-friendly materials and sustainable manufacturing practices are paving the way for innovative solutions in fence post production.

Manufacturers who invest in modern fence post making machines not only position themselves competitively in the market but also align with the growing consumer preference for durability and sustainability.

Conclusion

As industries continue to evolve, the importance of specialized machinery like fence post making machines cannot be understated. They represent a critical investment for manufacturers who aim to produce high-quality, durable, and efficient products that meet the demands of modern consumers. In a world where precision and speed are paramount, these machines are not merely tools but essential components of a successful manufacturing strategy, paving the way for a robust future in the fence post market. Through continued innovation and adaptation, the fence post making industry is poised to meet the challenges ahead, ensuring that quality fencing solutions are readily available for generations to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025