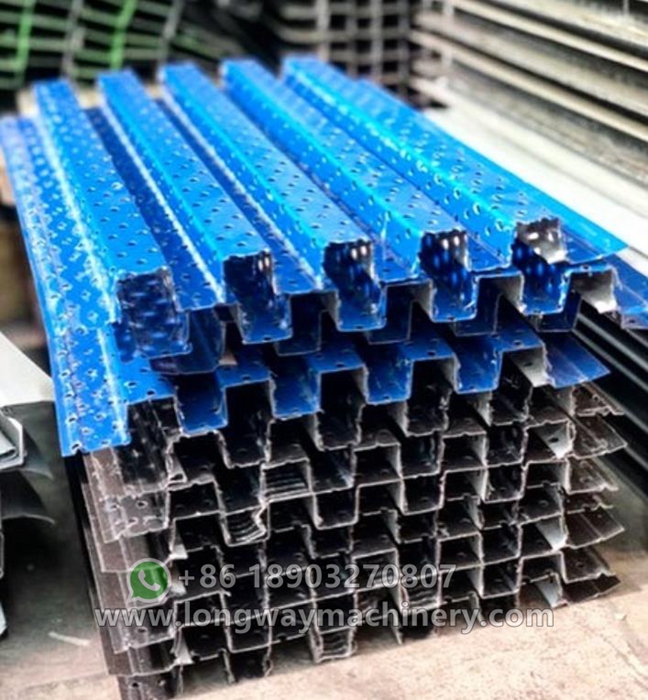

roof tiles machine for sale factory

Roof Tiles Machine for Sale A Comprehensive Guide for Factories

In the modern construction industry, the demand for high-quality roof tiles is on the rise. Roof tiles are not only essential for protecting buildings from the elements but also play a crucial role in enhancing the aesthetic appeal of roofs. For manufacturers looking to tap into this lucrative market, investing in a roof tiles machine is a critical step. This article explores the benefits, types, and considerations for factories interested in purchasing roof tiles machines.

The Importance of Roof Tiles

Roof tiles are an integral part of a building's architecture, offering durability, energy efficiency, and aesthetic charm. They are available in various materials, including clay, concrete, and even modern synthetic options. The preference for roof tiles over traditional roofing materials is driven by their longevity and low maintenance requirements. Consequently, manufacturers are presented with a robust market that showcases a growing need for innovative and efficient production techniques.

Key Features of Roof Tiles Machines

When considering a roof tiles machine for sale, it is essential to understand the features that will benefit your factory's operations. Here are some key attributes to look for

1. Automated Production Modern machines come equipped with automation technology, which enables high-speed production. This reduces labor costs and minimizes human error, leading to consistently high-quality tiles.

2. Versatility A machine that can produce different types of roof tiles—such as interlocking tiles or flat tiles—offers flexibility to the manufacturer. This versatility can help engage a wider range of clients and adapt to changing market trends.

3. Energy Efficiency With the global shift towards sustainable manufacturing, energy-efficient roof tiles machines are a wise investment. These machines not only reduce production costs but also lower the carbon footprint of the manufacturing process.

4. User-Friendly Interface An intuitive control system is essential for running the machine efficiently. This feature ensures that factory workers can easily operate the machine with minimal training, leading to increased productivity.

5. Durability and Maintenance Investing in a machine that is built to last will save costs on repairs and replacements in the long run. Look for machines made from high-quality materials with easily accessible parts for maintenance.

Types of Roof Tiles Machines

roof tiles machine for sale factory

There are several types of roof tiles machines available on the market, each designed to meet specific production needs

1. Concrete Roof Tiles Machines These machines are designed to produce concrete tiles using a mixture of cement, sand, and water. They are robust and capable of producing tiles in various shapes and colors.

2. Clay Roof Tiles Machines Specifically designed for clay tiles, these machines offer the ability to create high-fired products that are both durable and aesthetically pleasing. Techniques such as extrusion and pressing are used to shape the clay.

3. Synthetic Roof Tiles Machines With advancements in technology, synthetic materials are becoming popular in the roofing industry. Machines that produce membrane tiles or polymer-based tiles cater to this emerging market.

Considerations Before Purchase

Before purchasing a roof tiles machine, factories should consider the following factors to ensure a wise investment

1. Budget Determine the budget and assess the return on investment. While some machines may come with a higher upfront cost, their efficiency and durability can offer increased savings over time.

2. Supplier Reputation Research the manufacturers of roof tiles machines. Look for reputable suppliers with positive customer reviews and after-sales support. A strong partnership can provide assistance in installation and troubleshooting.

3. Customization Depending on the specific needs of the factory, consider whether the machine can be customized. Having the ability to adjust settings for different roof tile styles can enhance productivity.

4. Production Capacity Assess your production needs and choose a machine that can meet or exceed these requirements. A machine that is too small may limit growth, while one that is too large might result in unnecessary expenditure.

Conclusion

Investing in a roof tiles machine is a strategic move for factories aiming to capitalize on the booming construction market. By understanding the essential features, types of machines available, and crucial considerations before purchase, manufacturers can make informed decisions that align with their business goals. With the right equipment, creating high-quality roof tiles becomes not just a possibility, but a profitable reality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025