Jan . 25, 2025 20:33

Back to list

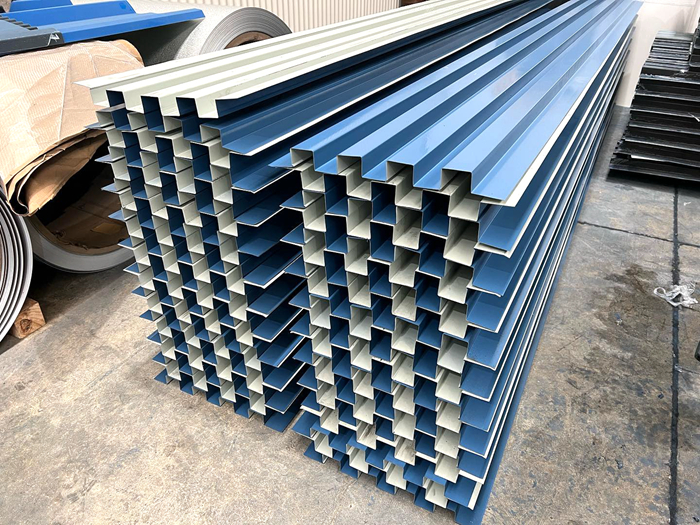

drip edge roll former for sale

Investing in a drip edge roll former is a smart choice for businesses in the building and roofing industries. As a pivotal component of modern roofing systems, drip edges are vital in guiding rainwater away from the fascia and into the gutter, thus preventing potential water damage. A drip edge roll former is therefore essential for businesses eager to meet industry demands efficiently and with precision.

When exploring drip edge roll formers for sale, it’s pivotal to engage with reputable manufacturers and distributors who provide comprehensive support including training, maintenance, and technical service. These partnerships ensure that the machine remains in optimal condition, further extending its lifespan and functional efficiency. This relationship is an investment in trustworthiness—key to building enduring client relationships and expanding market presence. Furthermore, aligning with suppliers offering robust warranties and service agreements provides an additional layer of security, ensuring that the business is safeguarded against unforeseen mechanical issues that could disrupt production. In essence, the trustworthiness of the supplier enhances the trustworthiness of your business’s offerings. Engagement in forums, workshops, and industry-specific networking events provides practical insights and firsthand experiences that are invaluable when making an informed decision. Peer recommendations often reveal nuances not immediately apparent in product brochures or sales pitches, ensuring a comprehensive understanding of the machine’s capabilities and operational demands. In conclusion, purchasing a drip edge roll former is about more than just acquiring a piece of machinery; it’s about elevating one’s standing within the industry as a provider of reliable, quality roofing solutions. By investing in equipment that exemplifies expertise and credibility, businesses can reinforce their market positions and ensure they not only meet but exceed client expectations. In a competitive industry landscape where every detail matters, owning a high-quality drip edge roll former symbolizes a commitment to excellence and trustworthiness that cannot be understated.

When exploring drip edge roll formers for sale, it’s pivotal to engage with reputable manufacturers and distributors who provide comprehensive support including training, maintenance, and technical service. These partnerships ensure that the machine remains in optimal condition, further extending its lifespan and functional efficiency. This relationship is an investment in trustworthiness—key to building enduring client relationships and expanding market presence. Furthermore, aligning with suppliers offering robust warranties and service agreements provides an additional layer of security, ensuring that the business is safeguarded against unforeseen mechanical issues that could disrupt production. In essence, the trustworthiness of the supplier enhances the trustworthiness of your business’s offerings. Engagement in forums, workshops, and industry-specific networking events provides practical insights and firsthand experiences that are invaluable when making an informed decision. Peer recommendations often reveal nuances not immediately apparent in product brochures or sales pitches, ensuring a comprehensive understanding of the machine’s capabilities and operational demands. In conclusion, purchasing a drip edge roll former is about more than just acquiring a piece of machinery; it’s about elevating one’s standing within the industry as a provider of reliable, quality roofing solutions. By investing in equipment that exemplifies expertise and credibility, businesses can reinforce their market positions and ensure they not only meet but exceed client expectations. In a competitive industry landscape where every detail matters, owning a high-quality drip edge roll former symbolizes a commitment to excellence and trustworthiness that cannot be understated.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products