drip edge machine company

The Evolution and Importance of Drip Edge Machine Companies

In the world of modern construction and roofing, the importance of efficient manufacturing processes cannot be overstated. Among the key players in this sector are specialized companies that focus on manufacturing drip edge machines. These machines are vital for producing roof drip edges that protect buildings from water damage, ensuring longevity and structural integrity. This article explores the significance of drip edge machine companies and their impact on the construction industry.

Understanding Drip Edge and Its Importance

Drip edges are critical roofing components designed to direct water away from the roof's fascia and prevent water from seeping underneath the shingles or roofing material. Without adequate protection, roofs can suffer from various issues, including mold growth, wood rot, and structural damage. Thus, integrating a reliable drip edge into roofing systems is essential for safeguarding properties.

In recognizing the importance of drip edges, the demand for effective and efficient manufacturing processes has surged, leading to the rise of specialized drip edge machine companies. These firms are at the forefront of designing, manufacturing, and providing cutting-edge machinery tailored for producing drip edges consistently and accurately.

The Role of Drip Edge Machine Companies

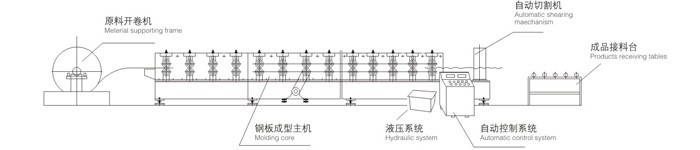

Drip edge machine companies specialize in developing machines that meet the unique requirements of the roofing industry. These machines are engineered to produce high-quality drip edges with varying dimensions and profiles to cater to different architectural styles and regional needs.

1. Innovation and Technology Drip edge machine companies invest in research and development to keep pace with technological advancements. Modern machines feature automation and computer numerical control (CNC) capabilities, allowing for precise cuts and consistent results. This innovation not only boosts production efficiency but also reduces material wastage, ultimately contributing to cost savings for manufacturers.

2. Customization Different markets have varying demands for drip edge specifications. Drip edge machine manufacturers offer customization options that enable clients to produce bespoke drip edges tailored to specific projects. This flexibility enhances customer satisfaction and solidifies long-term partnerships between manufacturers and contractors.

drip edge machine company

3. Training and Support Beyond manufacturing, drip edge machine companies provide essential training and support for their clients. Understanding how to operate these machines effectively is crucial for maximizing productivity. Companies often offer training programs, manuals, and online resources to ensure that their customers can leverage the full potential of the machinery.

Market Trends and Future Prospects

As the construction industry continues to evolve, drip edge machine companies are seeking to expand their market presence. The ongoing growth in sustainable building practices is influencing the production of eco-friendly materials and components. Drip edge technology is no exception, with some manufacturers exploring options for producing recyclable materials or energy-efficient machines.

Additionally, globalization is opening new markets for drip edge machine companies. With the right technology and adaptability, these companies can tap into emerging economies where construction activity is booming, thus presenting opportunities for growth and diversification.

Challenges Ahead

Despite the promising outlook, drip edge machine companies face several challenges. Fluctuating material costs, regulatory changes, and the need to stay ahead of competitors can impact operations. Moreover, as the roofing industry increasingly emphasizes sustainability, manufacturers must adapt quickly to produce environmentally friendly solutions.

Conclusion

In conclusion, drip edge machine companies play a pivotal role in the construction and roofing industries. By focusing on innovation, customization, and customer support, they contribute significantly to producing high-quality drip edges that protect buildings from water damage. As the construction landscape evolves, these companies are well-positioned to remain crucial players, adapting to new trends and technologies while meeting the needs of a changing market. The future looks bright for drip edge machines, as their essential role in construction cannot be ignored.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025