auto roll forming machine stacker

The Auto Roll Forming Machine Stacker A Revolution in Manufacturing Efficiency

In today’s fast-paced industrial landscape, efficiency and precision are paramount. Among the innovations that have emerged to meet these demands is the auto roll forming machine stacker. This sophisticated system enhances the productivity of roll forming operations, ensuring that manufacturers can keep up with the growing requirement for high-quality metal components.

Understanding Roll Forming

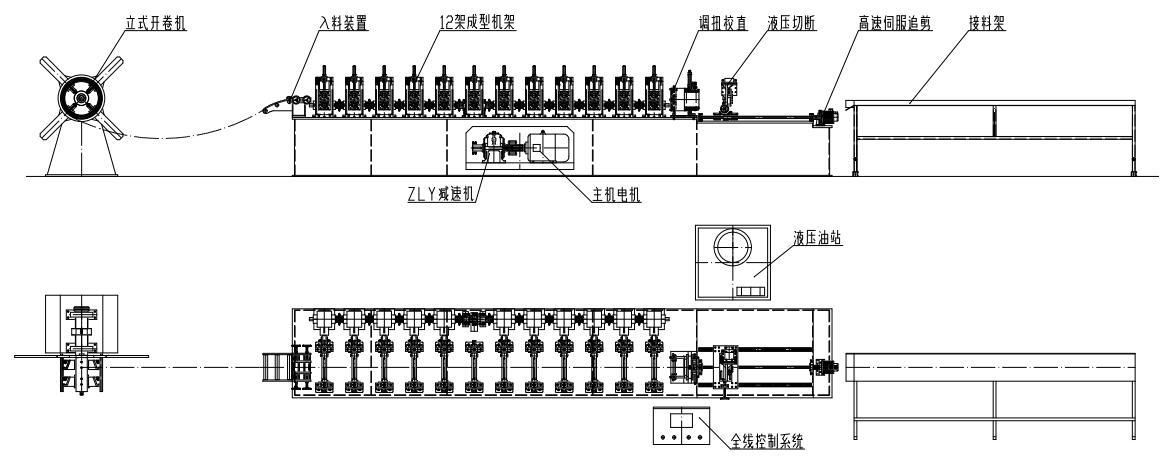

Before we delve into the auto stacker, it’s essential to understand the roll forming process. Roll forming is a method used to shape metal into desired profiles by passing material through a series of contoured rollers. The result is a continuous length of metal with a uniform cross-section, which can be used in various applications, including construction, automotive, and appliance manufacturing.

The traditional roll forming process, while efficient, often involves labor-intensive handling procedures, particularly when it comes to stacking and managing the final product. This is where auto roll forming machine stackers come into play, revolutionizing the handling and logistics of the formed elements.

What is an Auto Roll Forming Machine Stacker?

An auto roll forming machine stacker is an automated solution designed to streamline the stacking of finished roll-formed products. By integrating advanced robotics and automation technologies, these stackers can automatically pick, sort, and stack metal components right off the production line. The primary goal is to minimize manual labor, reduce the risk of injury, and enhance overall throughput.

Key Features of Auto Roll Forming Machine Stackers

1. Automation and Precision These stackers employ robotic arms that can be programmed for precision handling of components. This level of automation not only reduces labor costs but also ensures a consistent output quality by minimizing human error.

2. Versatile Stacking Options Auto stackers can be customized to stack products in various configurations, whether in vertical columns, horizontal layers, or specific patterns. This versatility makes them applicable across different industries and product types.

3. Space Optimization With the ability to manage materials in a more organized manner, auto stackers help manufacturers save valuable floor space. Efficient stacking allows for better inventory management and easier access to finished products.

auto roll forming machine stacker

4. Integrated Safety Features Modern auto stackers are equipped with safety mechanisms that protect both the machine and its operators. Sensors can detect obstructions, ensuring that operations are halted if anything goes awry, thereby preventing accidents.

5. Connectivity and Data Management Many state-of-the-art stackers come with IoT capabilities, allowing them to communicate with other machines in the production line. This feature enables real-time monitoring and data analytics, which can be crucial for streamlining operations and identifying bottlenecks.

Benefits to Manufacturers

The integration of an auto roll forming machine stacker presents a multitude of benefits

- Increased Productivity Automated stacking significantly reduces downtime between production cycles, enabling manufacturers to enjoy higher output rates.

- Cost Efficiency By decreasing the need for manual labor and reducing the incidence of worker injury, companies can lower operational costs.

- Enhanced Safety With reduced human intervention in potentially dangerous tasks, workplace accidents decrease, creating a safer environment for employees.

- Quality Assurance The precision and consistency provided by automated systems lead to a lower defect rate, ensuring that products meet stringent quality standards.

Conclusion

The auto roll forming machine stacker is not just a piece of equipment; it represents a significant leap forward in the manufacturing process. By automating the stacking of roll-formed products, manufacturers can improve efficiency, enhance safety, and reduce costs. As industries continue to evolve, embracing automation technologies like auto stackers will be crucial for staying competitive. Moreover, as technology advances, we can expect to see even more innovative solutions that will further optimize the roll forming process, paving the way for a more efficient and productive future in manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025