Dual Layer Roof Panel Rolling Machine for Efficient Building Solutions

Double Layer Roof Sheet Roll Forming Machine An Overview

In the construction and manufacturing industry, efficiency and quality are paramount. One innovative solution that has gained prominence is the double layer roof sheet roll forming machine. This machine enhances productivity and versatility in producing various roofing sheets, meeting the diverse needs of modern construction projects.

What is a Double Layer Roof Sheet Roll Forming Machine?

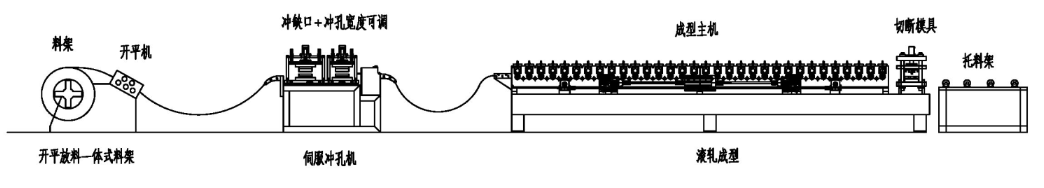

A double layer roof sheet roll forming machine is a sophisticated piece of equipment designed to manufacture two different profiles of roof sheets in a single pass. These machines can produce materials such as roof panels, wall panels, and corrugated sheets, all tailored to specific requirements of strength, durability, and aesthetics. The ability to form two layers in one process significantly optimizes space and production time while reducing costs and material wastage.

Key Features and Benefits

1. Dual Production Capability The primary advantage of this machine is its ability to create two distinct profiles—such as a corrugated layer and a tile layer—without the need for multiple machines. This feature not only saves space but also minimizes the investment required in acquiring and operating separate machines.

2. High Efficiency Double layer roof sheet roll forming machines are designed for speed and precision. With advanced automation and control systems, they can produce large volumes of sheets in a shorter time frame, thus increasing overall production efficiency.

3. Versatile Design Options The machine can be customized to produce various designs, colors, and materials based on the client’s specifications. This versatility makes it an attractive choice for manufacturers catering to different market segments, from residential constructions to large commercial projects.

double layer roof sheet roll forming machine

4. Cost-Effective Production By consolidating the production process into one machine, manufacturers can reduce operational costs associated with labor, maintenance, and machinery investment. The energy-efficient design of most modern roll forming machines further contributes to lower energy bills.

5. Durability and Quality The steel components produced by these machines are known for their durability and resistance to environmental factors. This quality makes them ideal for roofing applications where longevity and robustness are crucial.

Applications

The double layer roof sheet roll forming machine is widely used in various sectors. It is commonly employed in the construction of residential buildings, warehouses, factories, and agricultural buildings. Additionally, the machine also caters to the needs of the prefabricated construction industry, where quick assembly and strong materials are essential.

Maintenance and Care

Like any sophisticated machinery, proper maintenance is crucial for the longevity and optimal performance of the double layer roof sheet roll forming machine. Regular inspections, lubrication of moving parts, and timely replacement of worn-out components are vital to ensure uninterrupted production. Manufacturers should also ensure that operators are well-trained to minimize the risk of operational errors that could lead to machine damage.

Conclusion

The double layer roof sheet roll forming machine has revolutionized the way roofing materials are produced. By offering dual-layer capabilities, high efficiency, and customizable options, it stands out as an invaluable tool for manufacturers in the construction industry. As the demand for versatile and durable roofing materials continues to grow, investing in such advanced machinery will undoubtedly yield substantial returns in productivity and profitability. This technology exemplifies the continuous evolution of manufacturing processes, aligning with the industry's shift towards sustainability and efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025