Affordable Corrugated Metal Sheet Production Equipment for Efficient Manufacturing

Cheap Corrugated Iron Sheet Making Machine A Cost-Effective Solution for Construction

In recent years, the demand for affordable construction materials has surged, driving innovation and manufacturing efficiencies in various sectors. One notable advancement is the development of cheap corrugated iron sheet making machines, which play a pivotal role in the production of corrugated iron sheets – a highly sought-after material in the construction industry. This article delves into the significance of these machines, their operational mechanisms, and their benefits in both industrial and small-scale production settings.

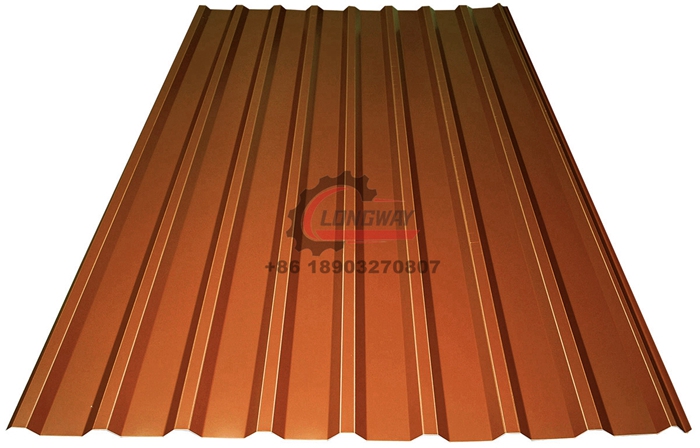

Understanding Corrugated Iron Sheets

Corrugated iron sheets are metal sheets that have been shaped into ridges and grooves. This unique design provides enhanced strength and durability, making them an ideal choice for roofing, wall cladding, and various structural applications. Their corrosion resistance, lightweight, and relatively low manufacturing cost further cement their popularity across the globe. As countries experience rapid urbanization, the demand for these sheets has risen, prompting manufacturers to seek efficient production methods.

The Role of Corrugated Iron Sheet Making Machines

Corrugated iron sheet making machines are specialized equipment designed to transform flat sheets of iron into a corrugated profile. These machines can be categorized into two main types manual and automated. Manual machines are typically less expensive and suitable for small-scale operations, while automated machines offer higher production capacity and efficiency, making them ideal for larger manufacturing operations.

How They Work

The basic operation of a corrugated iron sheet making machine involves several key processes. Initially, flat steel sheets are fed into the machine, where they undergo a series of rolls. These rollers shape the sheets into the desired corrugated form while simultaneously cutting them to length. Advanced machinery often incorporates integrated systems for coating and painting, allowing manufacturers to produce finished products ready for installation.

Automation within these machines enhances precision and reduces labor costs. Operators can adjust settings easily, ensuring consistent product quality. Many modern machines also feature digital controls, enabling manufacturers to optimize production cycles and minimize waste.

cheap corrugated iron sheet making machine

Benefits of Cheap Corrugated Iron Sheet Making Machines

1. Cost Efficiency The most significant advantage is the reduction in manufacturing costs. By investing in a cheap corrugated iron sheet making machine, businesses can produce their materials in-house, mitigating the need for expensive purchases from suppliers. This is especially beneficial for construction firms and contractors who require large quantities of sheets.

2. Faster Production Rates Automated machines significantly speed up the production process. With the capability to produce numerous sheets in a short time, manufacturers can respond quickly to market demands and undertake larger projects without delays.

3. Customization With in-house manufacturing, companies can easily customize sheet sizes and profiles according to specific project requirements. This flexibility proves invaluable, as it allows for tailored solutions that meet varying architectural designs.

4. Quality Control Owning a corrugated iron sheet machine enables operators to maintain strict quality control measures. By overseeing the production process, defects can be identified and rectified immediately, ensuring that only high-quality materials leave the facility.

5. Environmental Impact Many sheet-making machines now utilize eco-friendly technologies, reducing the carbon footprint of production. By minimizing waste and energy usage, manufacturers can align their operations with sustainability goals, appealing to an increasingly eco-conscious market.

Conclusion

The emergence of cheap corrugated iron sheet making machines represents a significant advance in the construction material manufacturing sector. By offering cost-effective, efficient, and customizable production methods, these machines empower businesses to meet growing demands while maintaining high standards of quality. As construction continues to evolve with urbanization and modernization, these machines will undoubtedly play a crucial role in shaping the future of building materials. For new entrepreneurs and established firms alike, investing in such technology not only enhances efficiency but also strengthens their market position.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025