Jan . 24, 2025 03:01

Back to list

cladding roll forming machine

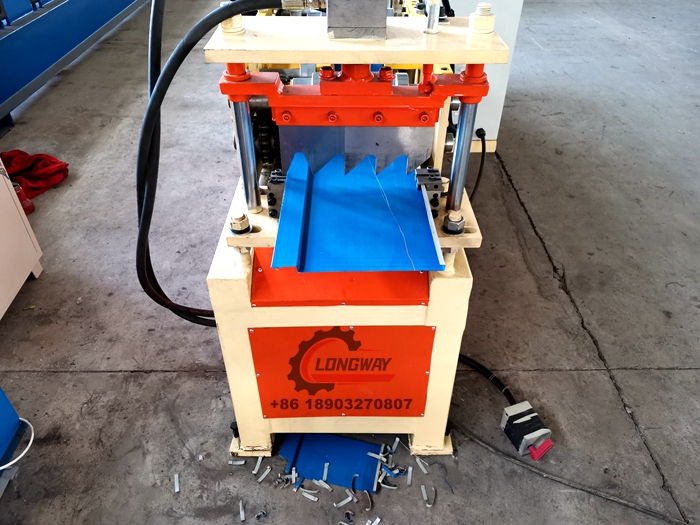

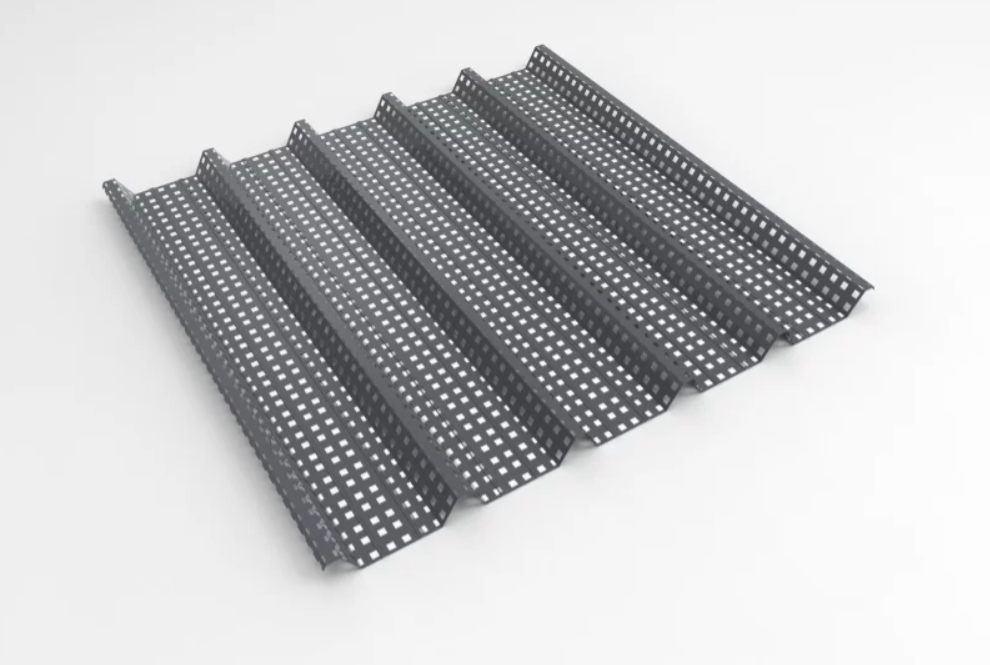

Navigating the landscape of modern construction technology often brings us face-to-face with innovations that redefine efficiency and precision. Among these, the double layer forming machine stands out as a revolutionary product, central to producing robust, aesthetic roofing and wall cladding solutions. This article explores the multifaceted aspects of this technology, underscoring its experience-backed features, professional insights, authoritative voice, and trustworthiness.

Authoritative insights reveal that the adoption rate of double layer forming machines is on the rise globally. Industry leaders advocate for integrating such technology into manufacturing processes, citing efficiency and versatility as key drivers. Recent industry reports have documented significant productivity gains in sectors employing these machines, with some companies reporting up to a 30% increase in output efficiency. These statistics underscore the machine's impact and affirm its standing as a pivotal tool in modern construction tech suites. The trustworthiness of double layer forming machines is reflected in the certifications and standards they uphold. Most machines are compliant with international safety and quality standards such as ISO 9001, ensuring they meet rigorous industry benchmarks. This compliance provides consumers with confidence in the machine's capabilities and safety, fostering trust in its continual performance. Manufacturers offer comprehensive support and warranties, further establishing a reliable framework for customers who invest in this technology. In conclusion, the double layer forming machine represents a convergence of advanced engineering, operational proficiency, and industry trust. Its capability to simultaneously produce varied profiles reduces operational complexities and enhances competitive advantage. As industries pivot towards more efficient and sustainable production strategies, the adoption of double layer forming machines is poised to become a mainstay in manufacturing disciplines. It embodies technological progress and operational excellence, setting a new standard for future innovations in the field. By embracing this technology, businesses position themselves at the forefront of construction innovation, ready to meet the demands of an ever-changing market landscape.

Authoritative insights reveal that the adoption rate of double layer forming machines is on the rise globally. Industry leaders advocate for integrating such technology into manufacturing processes, citing efficiency and versatility as key drivers. Recent industry reports have documented significant productivity gains in sectors employing these machines, with some companies reporting up to a 30% increase in output efficiency. These statistics underscore the machine's impact and affirm its standing as a pivotal tool in modern construction tech suites. The trustworthiness of double layer forming machines is reflected in the certifications and standards they uphold. Most machines are compliant with international safety and quality standards such as ISO 9001, ensuring they meet rigorous industry benchmarks. This compliance provides consumers with confidence in the machine's capabilities and safety, fostering trust in its continual performance. Manufacturers offer comprehensive support and warranties, further establishing a reliable framework for customers who invest in this technology. In conclusion, the double layer forming machine represents a convergence of advanced engineering, operational proficiency, and industry trust. Its capability to simultaneously produce varied profiles reduces operational complexities and enhances competitive advantage. As industries pivot towards more efficient and sustainable production strategies, the adoption of double layer forming machines is poised to become a mainstay in manufacturing disciplines. It embodies technological progress and operational excellence, setting a new standard for future innovations in the field. By embracing this technology, businesses position themselves at the forefront of construction innovation, ready to meet the demands of an ever-changing market landscape.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products