Feb . 08, 2025 04:50

Back to list

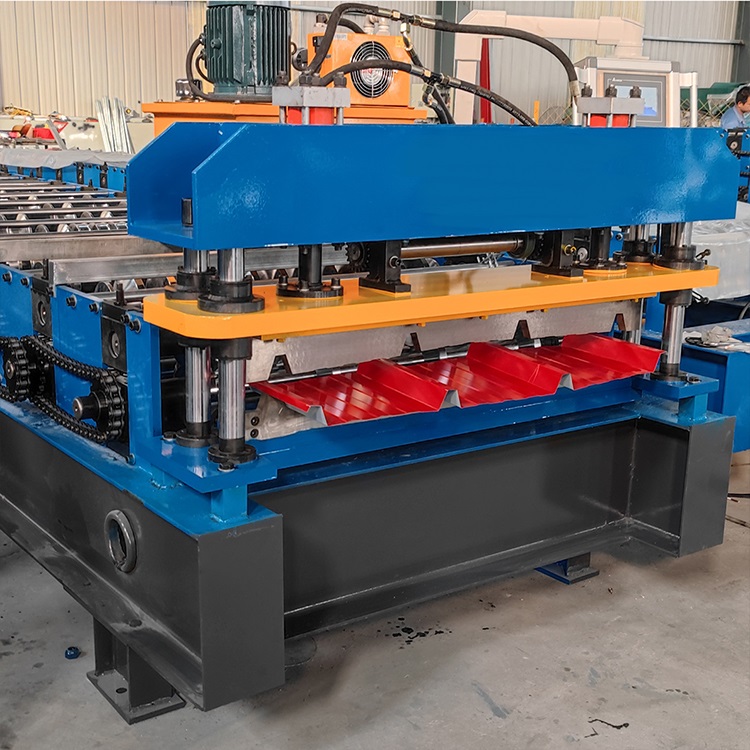

cladding roll forming machine

Double layer cold roll forming machines stand as a pivotal innovation in the realm of industrial manufacturing, embodying cutting-edge technology and engineering expertise. Designed to improve efficiency and versatility, these machines are essential for producing high-quality metal profiles used across various industries, including construction, automotive, and energy sectors.

The adoption of double layer cold roll forming machines also aligns with contemporary manufacturing trends prioritizing automation and digitalization. The machines are equipped with automated systems for process monitoring and quality control, thereby reducing the need for manual supervision and enabling operators to focus on optimizing other operational aspects. This integration into digital manufacturing landscapes represents a step towards smart factories of the future, characterized by interconnected systems and streamlined production processes. Practical experience among users further illuminate the machine's effectiveness. Operators report a smoother workflow due to the machine’s dual-layer capacity and user-friendly interfaces, which simplify training and reduce the likelihood of operator error. This ease of use translates into faster implementation and a quick turnaround from installation to full-scale production. In summary, the double layer cold roll forming machine embodies excellence in engineering and efficiency, positioning itself as a cornerstone technology in modern industry. Its design intricacies reflect a balanced blend of functionality, precision, and durability, supporting businesses in achieving their production goals while reducing costs and enhancing output quality. As industries continue to evolve with technological advancements, the value provided by such machinery underscores the necessity of investment in high-quality, adaptable solutions tailored to meet the ever-growing demands of global manufacturing.

The adoption of double layer cold roll forming machines also aligns with contemporary manufacturing trends prioritizing automation and digitalization. The machines are equipped with automated systems for process monitoring and quality control, thereby reducing the need for manual supervision and enabling operators to focus on optimizing other operational aspects. This integration into digital manufacturing landscapes represents a step towards smart factories of the future, characterized by interconnected systems and streamlined production processes. Practical experience among users further illuminate the machine's effectiveness. Operators report a smoother workflow due to the machine’s dual-layer capacity and user-friendly interfaces, which simplify training and reduce the likelihood of operator error. This ease of use translates into faster implementation and a quick turnaround from installation to full-scale production. In summary, the double layer cold roll forming machine embodies excellence in engineering and efficiency, positioning itself as a cornerstone technology in modern industry. Its design intricacies reflect a balanced blend of functionality, precision, and durability, supporting businesses in achieving their production goals while reducing costs and enhancing output quality. As industries continue to evolve with technological advancements, the value provided by such machinery underscores the necessity of investment in high-quality, adaptable solutions tailored to meet the ever-growing demands of global manufacturing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products