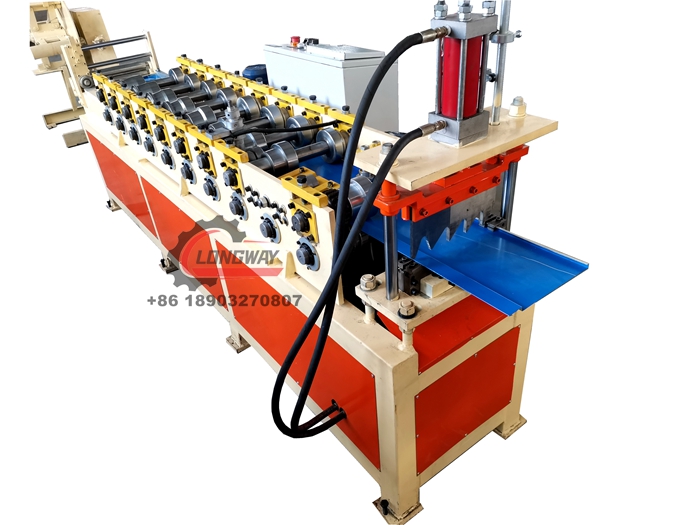

double deck roll forming machine company

Double Deck Roll Forming Machine Revolutionizing Metal Fabrication

In the modern manufacturing landscape, efficiency and versatility are paramount. One of the tools that exemplifies these qualities is the double deck roll forming machine. This innovative machinery has transformed the way metal components are fabricated, allowing companies to enhance productivity while reducing waste.

A double deck roll forming machine is designed to produce two profiles simultaneously, significantly increasing output without compromising quality. This capability is especially advantageous for industries that require high volumes of metal parts, such as construction, automotive, and appliances. By utilizing two sets of rollers, manufacturers can efficiently create complex and precise designs in a single pass, streamlining the production process.

The operational mechanism of a double deck roll forming machine involves feeding a flat metal strip into the machine, which then passes through a series of rollers. These rollers progressively shape the metal into the desired profile. The dual setup allows for the production of two different profiles—such as C and Z sections—at the same time, eliminating the need to switch between machines or setups. This not only saves time but also reduces labor costs and enhances the overall efficiency of the manufacturing process.

double deck roll forming machine company

One notable advantage of using a double deck roll forming machine is its ability to accommodate various materials, including steel, aluminum, and other alloys. This versatility enables manufacturers to cater to different market demands and adapt to changing industry standards. Furthermore, these machines can be customized to produce specific profiles and dimensions, making them suitable for a wide range of applications.

In addition to efficiency and versatility, double deck roll forming machines are equipped with advanced technology that ensures precision. Many models incorporate computer numerical control (CNC) systems, allowing for greater control over the production process. This results in higher consistency in product quality and minimizes the risk of errors that can occur in traditional manufacturing methods.

Moreover, the double deck design contributes to sustainability efforts in manufacturing. By producing two profiles simultaneously, these machines significantly reduce material waste, making them an environmentally friendly option. As industries increasingly prioritize sustainability, the adoption of such machines will likely continue to grow.

In conclusion, the double deck roll forming machine is a game-changer in the realm of metal fabrication. Its ability to produce multiple profiles simultaneously, adapt to various materials, and maintain high precision makes it an indispensable asset for modern manufacturers. As the industry evolves, investing in advanced machinery like the double deck roll forming machine will be crucial for companies aiming to stay competitive and meet the demands of a rapidly changing market. With its blend of efficiency, versatility, and sustainability, this machinery is well-positioned to lead the future of metal component production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025