sheet metal coil slitter

Understanding Sheet Metal Coil Slitters

Sheet metal coil slitters are essential machines in the manufacturing sector for processing and transforming large metal coils into usable strips or sheets. These machines are employed in various industries, including automotive, construction, electronics, and HVAC systems, due to the growing demand for precision metal products. This article will explore the workings of sheet metal coil slitters, their benefits, and applications, highlighting their role in enhancing production efficiency.

What is a Sheet Metal Coil Slitter?

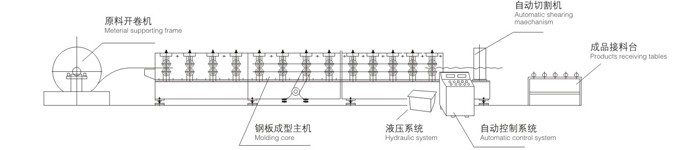

A sheet metal coil slitter is a specialized cutting machine designed to slice a large roll of metal, known as a coil, into narrower strips. The base component of a slitting line includes an uncoiler, slitting stations with rotary knives, and a recoiler that collects the finished strips. The slitting process typically involves unwinding the coil, feeding it through the slitting knives that cut it into desired widths, and then recoiling the cut strips for storage or further processing.

How Does a Slitting Machine Work?

The operation of a sheet metal coil slitter begins with the placement of a metal coil on the uncoiler. The coil is unwound and guided through a series of slitting knives. These knives can be adjusted to varying distances apart, allowing the operator to choose the width of the strips based on specific requirements. The knives rotate at high speeds, ensuring clean cuts without damaging the material.

After the slitting process, the newly cut strips pass through a series of rollers to ensure they are straight and then are recoiled into smaller coils. A quality slitting machine allows for simultaneous processing of multiple strips, significantly increasing productivity. Modern slitting lines are equipped with automation technologies that streamline the process further, reducing manual labor and increasing accuracy in cutting.

Advantages of Using Coil Slitters

1. Efficiency One of the primary advantages of coil slitter machines is their operational efficiency. Automated features minimize downtime and ensure optimal usage of raw materials.

sheet metal coil slitter

2. Precision Sheet metal coil slitters produce high-precision cuts, which are crucial in industries where tight tolerances are required. This minimizes waste and supports quality control.

3. Versatility These machines can handle a wide range of materials, including stainless steel, aluminum, copper, and various alloys. They can also accommodate different thicknesses and coatings, making them suitable for various applications.

4. Cost-effective By streamlining the cutting process and reducing material waste, coil slitters can lead to long-term savings for manufacturers, making them a cost-effective solution for producing metal strips.

5. Scalability The ability to adjust the slitting width and accommodate different materials means that businesses can easily scale their production capacity to meet changing demands in the market.

Applications of Sheet Metal Coil Slitters

The applications of sheet metal coil slitters are vast and varied. In the automotive industry, for example, precision strips are required for various components, from body panels to structural parts. In the construction sector, slit metal strips can be used for roofing, siding, and other applications requiring durable and reliable materials. Additionally, the electronics industry uses slit metal strip components for connectors and circuit boards, while HVAC systems may require specific metal strips for ductwork and unit construction.

Conclusion

In summary, sheet metal coil slitters serve a pivotal role in the manufacturing world by enabling efficient and precise cutting of metal coils. Their versatility and advanced technology make them indispensable for modern manufacturing processes across various industries. As demand for high-quality metal products continues to grow, the importance of reliable coil slitters will only increase, driving further innovations in slitting technology to meet the evolving needs of manufacturers.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025