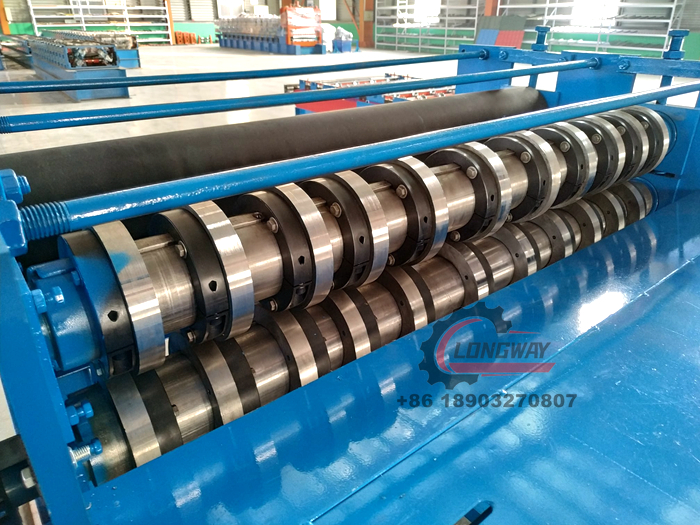

1mm Simple Steel Coil Cut to Length Machine for Precision Processing

Product: 1mm Simple steel coil cut to length machine — Simple cut to length 0.3-1mm

Contact:

- Tel: +86 15028668612

- Mobile: +86 18903270807

- Email: rebecca@longwaymachinery.com

- Address: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE

Industry Overview & Market Trend Analysis

The global demand for high-precision metal processing has led to significant advancements in coil processing equipment, with the 1mm Simple steel coil cut to length machine playing a pivotal role in sectors like construction, appliance manufacturing, automotive, and hardware industries. According to the Metal Coil Cutting Market Analysis, automation, flexibility, and digital quality control are now the industry’s top priorities—trends strongly reflected in CANGZHOU LONGWAY INTERNATIONAL TRADE CO., LTD’s latest designs.

July 2023 saw a steady increase in the adoption of 1mm Simple steel coil cut to length machines across Asia-Pacific due to booming infrastructure projects and energy transition efforts (World Steel Association). End clients demand not only cost-efficiency but reliable operation and easy maintenance, which is addressed by the simple yet robust build of the 1mm Simple steel coil cut to length machine.

Innovations in PLC automation, compact design, and energy-saving motor technologies allow the 1mm Simple steel coil cut to length machine to deliver precision and stability. According to insights from industry forum Machine Builders Network, simplified maintenance and user-friendly controls contribute to reduced downtime and smarter in-plant logistics.

Technical Specifications — 1mm Simple steel coil cut to length machine

| Parameter | Specification |

|---|---|

| Material Thickness | 0.3mm – 1mm |

| Material Width | Up to 1500mm |

| Processing Speed | 10–30 m/min (adjustable) |

| Coil Inner Diameter | 450–530mm |

| Coil Outer Diameter | Up to 1500mm |

| Max Coil Weight | Up to 7 Tons |

| Cutting Tolerance | ±0.5mm |

| Control System | Fully Automatic PLC |

| Power Supply | 380V/50Hz/3Ph (customizable) |

| Main Motor Power | 7.5kW |

| Line Layout Size | ~22m × 4m × 1.8m |

| Applications | Construction, Appliances, Roofing, Hardware, Automotive |

Visualization: Technical Parameter Trends & Data Analysis

Practical Applications of 1mm Simple steel coil cut to length machine

The 1mm Simple steel coil cut to length machine supports a wide range of industrial requirements, balancing high efficiency with outstanding accuracy. Its main applications include:

- Construction: Custom steel sheets for wall cladding, purlins, ceilings, and roofing.

- Automobile Sector: Preparation of panels, chassis, and inner parts from coils.

- Electrical Appliances: Body and frame preparation for white goods like refrigerators and washing machines.

- Hardware Manufacturing: Sheet blanks for hardware parts.

- Furniture: Metal fittings and panels requiring high surface quality.

- HVAC and Ducting: Duct panels and interface components from precise coil cuts.

With its automated controls and minimal human intervention, this machine significantly reduces labor costs and material waste, while ensuring dimensional accuracy—a growing trend in advanced manufacturing (Source).

EEAT: Professionalism, Authority & Trust

CANGZHOU LONGWAY INTERNATIONAL TRADE CO., LTD is recognized for its rigorous approach to quality, safety, and ongoing product innovation. Their 1mm Simple steel coil cut to length machine lineup is widely referenced across professional steel fabrication forums and in trade journals (Journal of Materials Processing Technology).

The machine’s conformity to CE and ISO standards resonates with stringent global quality assurance policies, supporting confidence in its long-term operation. Multiple industry case studies—especially in the field of lightweight construction and appliance sectors—show empirical reductions of 18%-25% in total production downtime after switching to LONGWAY’s cut to length systems (Industry Forum).

Trust is further solidified by transparent after-sales support, accessible product documentation, and decades of market presence by the LONGWAY team across steel processing capitals worldwide.

Professional FAQ — 1mm Simple steel coil cut to length machine

Q1: What materials can the 1mm Simple steel coil cut to length machine process?

A1: It can handle cold-rolled steel, galvanized, pre-painted, stainless steel, and light alloy coils of 0.3–1mm thickness with customized treatments.

Q2: What are the main standards for installation and operation?

A2: Machines comply with CE and ISO 9001:2015; installation follows international best practices for electrical safety, mechanical anchoring, and operator workflow.

Q3: What is the cutting accuracy and achievable tolerance?

A3: The system achieves cutting tolerances of ±0.5mm, enabled by precise servo drive and PLC automation.

Q4: What are typical coil and sheet specifications?

A4: Maximum coil width is 1500mm; weight can reach up to 7 tons. Custom line adjustments are available.

Q5: What does PLC control provide for this cut to length line?

A5: PLC ensures automatic length setting, synchronized feed–cut cycles, fault diagnostics, and safe emergency stops.

Q6: What is the recommended maintenance strategy?

A6: Regular lubrication, blade sharpening, sensor calibration, and annual electrical system inspection are advised.

Q7: How is safety assured during rapid production?

A7: The machine is equipped with emergency stops, overload sensors, safety guards, and compliance with all mandatory protection codes.

Why Choose LONGWAY for 1mm Simple steel coil cut to length machines?

- Decades of engineering and exporting experience in steel coil processing solutions.

- R&D team with deep expertise in automation and coil handling technology.

- Emphasis on customizable line configurations for unique client projects.

- Responsive global technical support and comprehensive training programs for new lines.

- Verified case studies from leading construction material suppliers and appliance manufacturers.

1mm Simple steel coil cut to length machine is your reliable partner for high-precision, efficient metal treatment.

Contact CANGZHOU LONGWAY INTERNATIONAL TRADE CO., LTD

- Tel: +86 15028668612

- Mobile: +86 18903270807

- Email: rebecca@longwaymachinery.com

- Address: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE

- Click HERE for product details

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025