door roll forming machine companies

The Future of Door Roll Forming Machines Innovations and Leading Companies

In the dynamic world of manufacturing, door roll forming machines have emerged as essential tools for producing high-quality door frames with precision and efficiency. These machines are designed to convert flat metal sheets into intricate shapes used in various doors, including residential, commercial, and industrial applications. As the demand for customized and durable doors continues to grow, companies that specialize in door roll forming machines are leveraging innovative technologies to meet market needs.

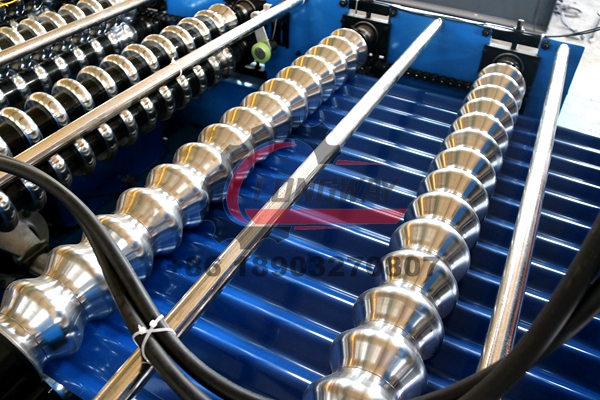

Understanding Door Roll Forming Machines

At its core, a door roll forming machine operates by feeding a coil of metal through a series of rollers that shape the material into the desired profile. This continuous process is highly efficient, allowing manufacturers to produce uniform door components at high speeds. The benefits of using roll forming technology include reduced material waste, enhanced production speed, and the ability to create complex shapes that are crucial for modern door designs.

Key Advantages of Using Door Roll Forming Machines

1. Cost-Effectiveness With lower material waste and faster production speeds, door roll forming machines can significantly reduce manufacturing costs. This is especially important in competitive markets where price pressures are prevalent.

2. Precision and Consistency These machines are engineered for high precision, ensuring that each door component meets strict quality standards. Consistency in production helps in maintaining the structural integrity of doors, which is vital for security and longevity.

3. Versatility Door roll forming machines can be customized to produce a variety of door styles and sizes. This flexibility allows manufacturers to cater to diverse customer needs, from traditional designs to contemporary aesthetics.

4. Durability Doors produced using roll forming technology are generally more robust due to the properties of the materials used, which can include steel, aluminum, or other alloys. This leads to doors that can withstand wear and tear over time, providing better value for consumers.

door roll forming machine companies

Leading Companies in the Door Roll Forming Machine Industry

Several prominent companies have established themselves as leaders in the door roll forming machine sector. These companies are known for their innovation, quality, and customer support.

1. FIMI S.p.A. An Italian company famed for its advanced roll forming solutions, FIMI has a wide range of machines that cater to the production of various door types. They focus on technological innovations that enhance efficiency and reduce production costs.

2. Zhangjiagang Tairong Machinery Co., Ltd. This Chinese manufacturer specializes in roll forming machines and is known for its cost-effective solutions. Driven by research and development, Tairong continually invests in improving its machine capabilities to meet the evolving needs of the market.

3. DREWO Technology GmbH Based in Germany, DREWO is recognized for its high-precision roll forming machines. Their commitment to quality and innovation has made them a preferred choice for manufacturers looking for reliable door production solutions.

4. KRB Machinery An American company, KRB focuses on designing and manufacturing CNC machinery, including roll formers for door frames. Their machines are designed for ease of use and integration with existing operations, making them ideal for small to medium-sized manufacturers.

The Future of Door Roll Forming Machines

As the manufacturing landscape evolves, so does the technology behind door roll forming machines. Innovations such as automation, artificial intelligence, and smart manufacturing are set to transform the industry. These technologies will not only enhance efficiency but also improve the accuracy of production processes. Moreover, the growing emphasis on sustainability will likely lead manufacturers to develop machines that use eco-friendly materials and processes.

In conclusion, as the demand for quality door components rises, so does the importance of door roll forming machines and the companies behind them. The industry is on the brink of significant transformation, driven by technological advancements and a commitment to meeting the diverse needs of consumers. For manufacturers, investing in innovative roll forming capabilities will be essential to stay competitive in this ever-evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025