Stud Manufacturing Equipment Production Facility Overview

The Evolution and Impact of Stud Making Machine Factories

In the modern manufacturing landscape, the production of fasteners, particularly studs, plays a crucial role across various industries. Studs, often utilized in construction, automotive, and manufacturing applications, require specific machinery for their efficient production. This is where stud making machine factories come into play, providing essential tools that streamline the manufacturing process and enhance productivity.

The Importance of Studs in Manufacturing

Studs are an integral part of countless structures and machines. They serve as connectors, providing structural strength and stability by fastening components together. The applications range from simple household items to complex automotive parts and large-scale construction projects. Given their ubiquitous use, the demand for high-quality studs is consistent, necessitating efficient production methods that can be achieved through specialized machinery.

Advancements in Stud Making Machine Technology

Stud making machines have come a long way since their inception. Initially, the production of studs was a tedious manual process, requiring skilled labor to shape and assemble each component. However, technological advancements have paved the way for fully automated stud making machines that significantly reduce labor costs and increase production efficiency.

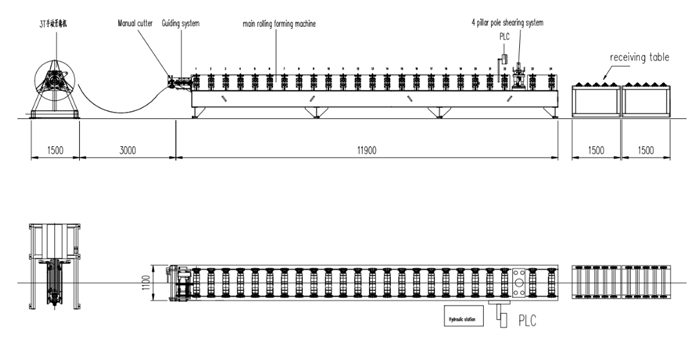

Modern stud making machines are equipped with advanced features such as programmable logic controllers (PLCs), which allow for precise control over the manufacturing process. These machines can produce a variety of stud shapes and sizes, ensuring that manufacturers can meet specific requirements. Additionally, the use of computer-aided design (CAD) software in the machine's programming enables customization and rapid prototyping, further increasing the adaptability of the production line.

Environmental Considerations

stud making machine factory

As industries evolve, so does their responsibility towards sustainability. Stud making machine factories are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes the use of energy-efficient machinery, which consumes less power, and the implementation of recycling processes for metal waste generated during production.

Furthermore, some manufacturers are exploring the use of biodegradable materials for certain stud applications. By focusing on sustainability, these factories not only comply with regulations but also appeal to a growing market segment that values environmentally responsible practices.

The Role of Industry 4.0

The advent of Industry 4.0 has transformed traditional manufacturing processes, including stud production. The integration of the Internet of Things (IoT) allows for real-time monitoring and data collection from stud making machines, leading to enhanced decision-making and operational efficiency. Factories can now predict maintenance needs, reducing downtime and ensuring consistent production quality.

Moreover, with the rise of smart factories, manufacturers can analyze large sets of data to optimize production schedules, reduce waste, and improve overall efficiency. This shift towards data-driven decision-making signifies a monumental change in how stud making factories operate, establishing them as leaders in innovative manufacturing practices.

Conclusion

Stud making machine factories are at the forefront of modern manufacturing, playing a pivotal role in various industries by producing essential fasteners that ensure the integrity and functionality of many products. As technology continues to advance, these factories are equipped with innovative machinery that boosts efficiency and adaptability while prioritizing sustainability.

The future of stud manufacturing looks promising, driven by advancements in technology and a commitment to environmentally responsible practices. By embracing these changes, stud making machine factories are not only meeting the demands of today's market but are also poised to tackle the challenges of tomorrow, ensuring that they remain vital players in the global manufacturing environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025