Feb . 04, 2025 04:21

Back to list

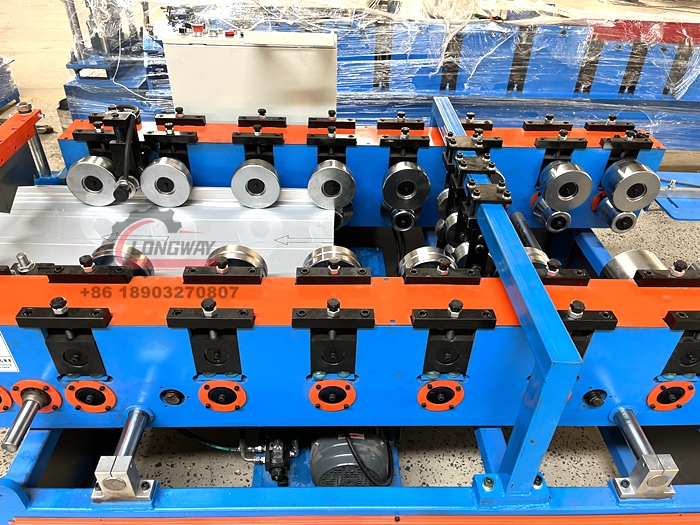

soffit roll former

The deck roll former stands at the forefront of modern manufacturing innovation, offering significant advancements in the construction and engineering industries. This specialized machine has revolutionized the way deck panels are produced, ensuring high precision, speed, and efficiency. Drawing on a blend of technical expertise and cutting-edge design, and underscoring its authority within the industry, its application is both widespread and impactful.

Furthermore, the deck roll former's innovative designs incorporate sustainability as a core focus, aligning with global efforts towards reducing carbon footprints in industrial processes. By utilizing materials more efficiently and requiring less energy than traditional manufacturing methods, these machines promote environmentally responsible practices. Sustainability not only advances its appeal in today’s market but also fortifies its authoritative presence as industries increasingly gravitate towards eco-friendly solutions. Expertise in the operation of deck roll formers is growing more accessible, thanks to comprehensive training programs offered by leading manufacturers. These programs are designed to ensure operators are proficient in the latest technological advances and maintenance techniques. As a direct result, this expertise ensures maximum uptime and prolongs the lifecycle of the equipment, reducing costs associated with repairs and replacements. To ensure the deck roll former remains credible, innovators in the space are consistently updating their models to keep pace with technological advances and the evolving needs of industries. This continuous enhancement process involves not only the integration of advanced technologies but also an ongoing dialogue with end-users to address their challenges and innovate solutions. In essence, the deck roll former is not just another tool in the manufacturing arsenal; it is a nucleus of expertise and innovation. Its role in transforming raw materials into structural components efficiently and reliably positions it as an indispensable asset in modern construction and manufacturing industries. As it continues to evolve, it fortifies its position of authority, ensuring trust and dependability are never compromised.

Furthermore, the deck roll former's innovative designs incorporate sustainability as a core focus, aligning with global efforts towards reducing carbon footprints in industrial processes. By utilizing materials more efficiently and requiring less energy than traditional manufacturing methods, these machines promote environmentally responsible practices. Sustainability not only advances its appeal in today’s market but also fortifies its authoritative presence as industries increasingly gravitate towards eco-friendly solutions. Expertise in the operation of deck roll formers is growing more accessible, thanks to comprehensive training programs offered by leading manufacturers. These programs are designed to ensure operators are proficient in the latest technological advances and maintenance techniques. As a direct result, this expertise ensures maximum uptime and prolongs the lifecycle of the equipment, reducing costs associated with repairs and replacements. To ensure the deck roll former remains credible, innovators in the space are consistently updating their models to keep pace with technological advances and the evolving needs of industries. This continuous enhancement process involves not only the integration of advanced technologies but also an ongoing dialogue with end-users to address their challenges and innovate solutions. In essence, the deck roll former is not just another tool in the manufacturing arsenal; it is a nucleus of expertise and innovation. Its role in transforming raw materials into structural components efficiently and reliably positions it as an indispensable asset in modern construction and manufacturing industries. As it continues to evolve, it fortifies its position of authority, ensuring trust and dependability are never compromised.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products