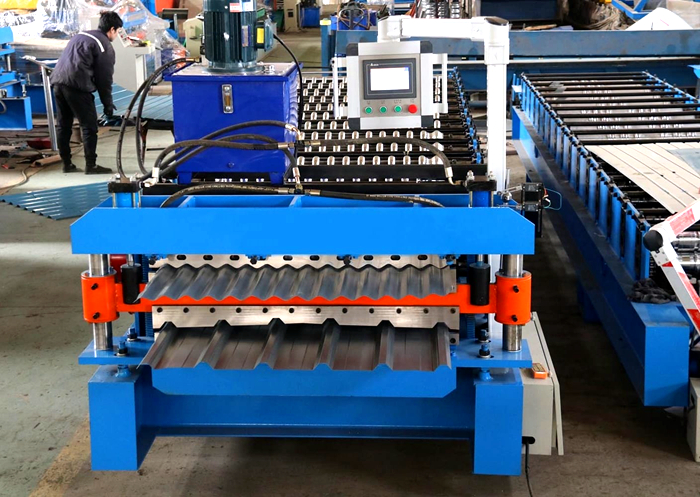

custom roof roll forming machine

The Advantages of Custom Roof Roll Forming Machines

In the competitive world of construction, efficiency and precision are paramount. One area that has seen significant advancements in technology is the production of roofing materials. Custom roof roll forming machines have become increasingly popular due to their ability to produce high-quality roofing components tailored to specific needs. This article explores the advantages of utilizing custom roof roll forming machines in modern manufacturing.

1. Tailored Solutions

One of the most significant benefits of custom roll forming machines is their ability to create tailored solutions for roofing components. Each construction project has unique demands, whether it is the size, shape, or design of the roofing materials. Custom machines can be programmed to produce a wide variety of profiles and dimensions, ensuring that each piece fits perfectly into the architectural plans. This level of customization not only enhances the aesthetic appeal of a building but also improves functionality by ensuring that all components fit securely and work harmoniously.

2. Improved Efficiency

Efficiency is crucial in any manufacturing process, especially in the building sector where time delays can lead to increased costs. Custom roof roll forming machines are designed for high-speed production, significantly reducing the time needed to generate roofing components. They automate the entire process, from raw material input to finished product output, which minimizes human error and increases the overall throughput. This streamlined operation allows manufacturers to meet tight deadlines while maintaining high-quality standards.

While the initial investment in custom roll forming technology may seem substantial, the long-term savings can be significant. By producing roofing components in-house, manufacturers can cut down on material waste and reduce transportation costs associated with sourcing pre-fabricated materials. Additionally, the durability and quality of products produced on these machines lead to fewer repairs and replacements over time, resulting in further cost savings.

custom roof roll forming machine

4. Versatile Material Options

Custom roof roll forming machines can handle a variety of materials, including steel, aluminum, and even copper. This versatility allows manufacturers to offer a broader range of products to their clients. Depending on the project's requirements, different materials may be used for different applications, and a custom machine can easily adapt to produce the specified material. This flexibility helps builders and architects to choose the best material for their projects while still maintaining efficiency.

5. Enhanced Structural Integrity

Roofing components produced with custom roll forming machines are engineered for structural integrity. The precise forming process ensures that each piece is uniform, consistent, and strong, which significantly contributes to the overall durability of the roof. This is especially crucial in regions prone to severe weather conditions, where high-quality roofing materials can make a significant difference in a building's resilience.

6. Eco-Friendly Production

As environmental concerns continue to rise, industries are seeking ways to reduce their carbon footprint. Custom roof roll forming machines can be designed for eco-friendly production practices. The automated processes often lead to higher material efficiency and less waste. Additionally, manufacturers can opt for sustainable materials, contributing to a greener construction industry. This commitment to sustainability not only attracts eco-conscious clients but also promotes a positive brand image.

Conclusion

Custom roof roll forming machines represent a significant advancement in roofing material production. Their ability to provide tailored solutions, improve efficiency, and enhance structural integrity makes them a valuable investment for manufacturers in the construction industry. As technology continues to advance, we can expect even more innovations in this field, ultimately leading to better, more sustainable building practices. Adopting custom roll forming technology is not just a trend; it is a strategic move towards a more efficient and sustainable future in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025