Efficient Metal Stud Roll Forming Equipment for Construction and Renovation Projects

An Overview of Metal Stud Roll Forming Machines

In the construction and structural engineering industry, the demand for lightweight, durable, and efficient materials is ever-increasing. Among the innovations that have emerged to meet these needs, metal stud roll forming machines stand out as a pivotal technology. This article delves into the workings, advantages, and applications of metal stud roll forming machines.

What is Metal Stud Roll Forming?

Metal stud roll forming is a manufacturing process that transforms metal strips into various shapes, specifically metal studs used in wall framing systems. In essence, a roll forming machine takes a continuous strip of metal, typically cold-rolled steel, and passes it through a series of rollers that gradually shape the metal into the final product. These machines can produce metal studs in various gauges and profiles, allowing for customization to meet specific construction requirements.

The Mechanism of Roll Forming Machines

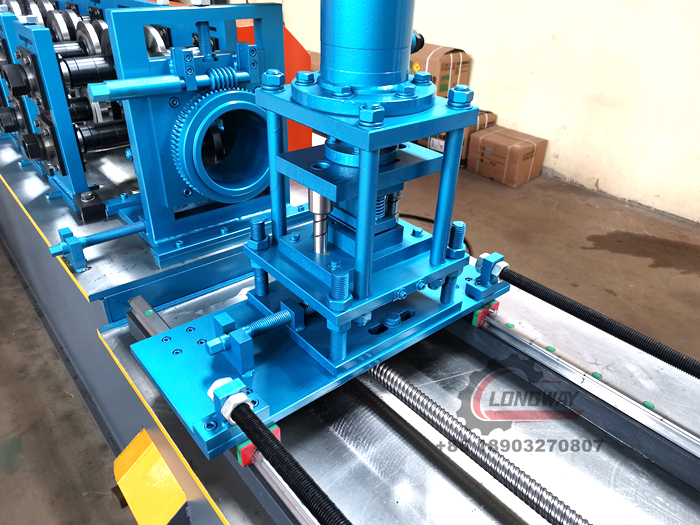

A typical metal stud roll forming machine comprises several essential components, including the decoiler, feeding system, roll forming stations, cut-off system, and control panel. The process begins with the decoiler, where the metal coil is loaded. The feeding system then unwinds the coil and feeds the metal strip into the roll forming stations, where it is shaped. The rollers apply pressure to the metal, forming it into the desired profile through a progressive series of steps. After the desired shape is achieved, a cut-off system trims the studs to the specified lengths.

The entire process is highly automated, allowing for high-volume production with minimal manual intervention. The control panel enables operators to monitor and adjust the machine’s settings, ensuring consistent quality and precision.

Advantages of Metal Stud Roll Forming Machines

1. Efficiency One of the primary advantages of metal stud roll forming machines is their efficiency. They can produce large quantities of metal studs quickly, significantly reducing production time compared to traditional methods.

metal stud roll forming machine

2. Cost-Effectiveness By optimizing material use and reducing waste, these machines lower the overall cost of manufacturing. Their ability to produce lightweight yet strong metal studs also contributes to cost savings during transportation and installation.

3. Customization Roll forming machines can be adjusted to create a variety of profiles and dimensions, allowing manufacturers to meet specific project needs. This flexibility is particularly beneficial in the construction industry, where different projects may require various stud configurations.

4. Durability Metal studs produced via roll forming are known for their strength and resilience. They are resistant to warping, decay, and pests, making them an excellent choice for both commercial and residential buildings.

5. Sustainability Metal is a recyclable material, and using metal studs can contribute to environmentally friendly construction practices. Roll forming processes also generate less waste compared to traditional sheet metal fabrication techniques.

Applications of Metal Studs

The versatility of metal studs makes them suitable for a wide range of applications. They are widely used in commercial construction for framing interior walls, partitions, and ceilings. In residential construction, metal studs are gaining popularity due to their lightweight nature and resistance to environmental factors. Additionally, metal studs are ideal for applications in areas where moisture is prevalent, such as bathrooms and kitchens, as they do not suffer from rot or mold like wood studs.

Conclusion

In conclusion, metal stud roll forming machines play a crucial role in modern construction practices. Their efficiency, cost-effectiveness, and ability to produce customized metal studs make them an invaluable tool for manufacturers and builders alike. As the construction industry continues to evolve, the significance of metal stud roll forming technology will undoubtedly grow, offering innovative solutions to meet the demands for sustainable and resilient building materials. By embracing this technology, manufacturers can streamline production processes, reduce costs, and ensure the delivery of high-quality products that meet the intricate needs of both commercial and residential projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025