custom metal stud and track roll forming machine

Custom Metal Stud and Track Roll Forming Machines An Overview

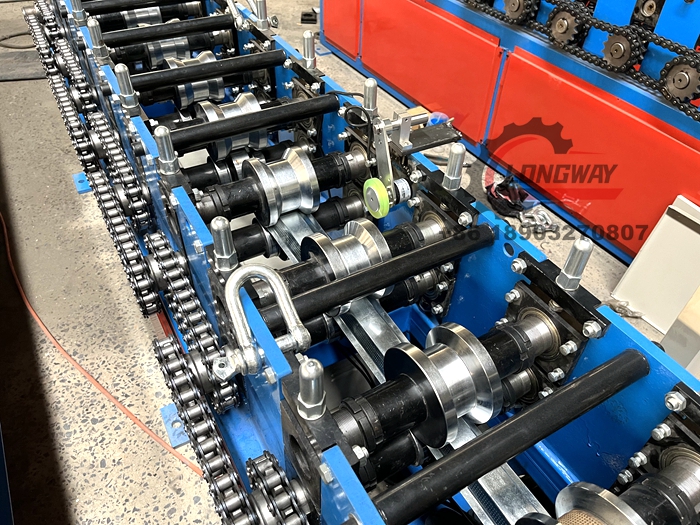

In the modern construction industry, efficiency, precision, and customization play pivotal roles in determining the success of any project. Among the essential tools that facilitate these attributes are custom metal stud and track roll forming machines. These advanced machines allow manufacturers to produce metal studs and tracks with unparalleled accuracy and speed, streamlining the process of building structures.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically galvanized steel or aluminum, is passed through a series of rollers, each of which gradually shapes the metal into the desired profile. This method is highly efficient and offers a number of advantages over other forms of metal fabrication.

One of the primary benefits of roll forming is its ability to produce long lengths of consistent profiles without the need for frequent changeovers. This efficiency translates into reduced labor costs and less material wastage, making roll forming an attractive option for large-scale production.

Customization Capabilities

The versatility of custom metal stud and track roll forming machines lies in their ability to create customized profiles tailored to specific construction needs. Builders often require different sizes, shapes, and strengths of metal studs and tracks to meet the unique demands of their projects. With advanced roll forming technology, manufacturers can design machines that produce a wide range of custom profiles without sacrificing quality.

For instance, a construction project may specify studs of varying heights and gauges depending on the structural requirements of different areas within a building. Using a custom roll forming machine, manufacturers can quickly adjust settings to produce the required specifications, ensuring that each component is perfect for its intended use.

Efficiency and Productivity

custom metal stud and track roll forming machine

The integration of automation and digital technologies into custom roll forming machines has transformed the landscape of metal construction products. Modern machines are often equipped with computerized controls that allow for precise adjustments to speed, temperature, and pressure at every stage of the forming process. This automation not only enhances the accuracy of the profiles produced but also significantly boosts the productivity of manufacturing operations.

Furthermore, many roll forming machines can operate at high speeds while maintaining quality

. This capability enables manufacturers to fulfill large orders in shorter timeframes, meeting tight deadlines without compromising on the integrity of the products.Sustainability Considerations

As the construction industry increasingly emphasizes sustainability, custom metal stud and track roll forming machines contribute to eco-friendly practices. Metal studs and tracks are often made from recycled materials, and the roll forming process typically produces minimal waste compared to traditional manufacturing methods.

Furthermore, using metal as a building material can enhance the energy efficiency of structures. Metal studs provide thermal insulation when used in conjunction with insulating materials, contributing to greener buildings. The durability and longevity of metal components also reduce the need for frequent replacements, further promoting sustainability in construction.

Conclusion

Custom metal stud and track roll forming machines represent a significant innovation within the construction industry, enabling manufacturers to produce high-quality, customized products with enhanced efficiency and sustainability. The ability to create versatile profiles tailored to specific project requirements makes these machines invaluable tools for builders and contractors.

In an era where time and resources are of the essence, investing in advanced roll forming technology is a strategic choice for any business looking to stay competitive in the ever-evolving construction landscape. As demand for customized metal components continues to rise, so too will the importance of roll forming machines in delivering high-performance solutions for builders and developers around the globe.

By harnessing the power of custom metal stud and track roll forming machines, manufacturers not only improve their operational capabilities but also contribute positively to the industry's move towards more sustainable practices—ultimately ensuring a brighter future for construction and building design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025