custom metal roof panel roll forming machine

Custom Metal Roof Panel Roll Forming Machine Revolutionizing Roofing Solutions

In the world of construction and architecture, efficiency and customization are key to meeting the demands of modern building projects. One of the most innovative solutions that has emerged is the custom metal roof panel roll forming machine. This state-of-the-art technology is transforming the way roofing materials are produced, offering advantages that cater to both large-scale industrial operations and small construction businesses.

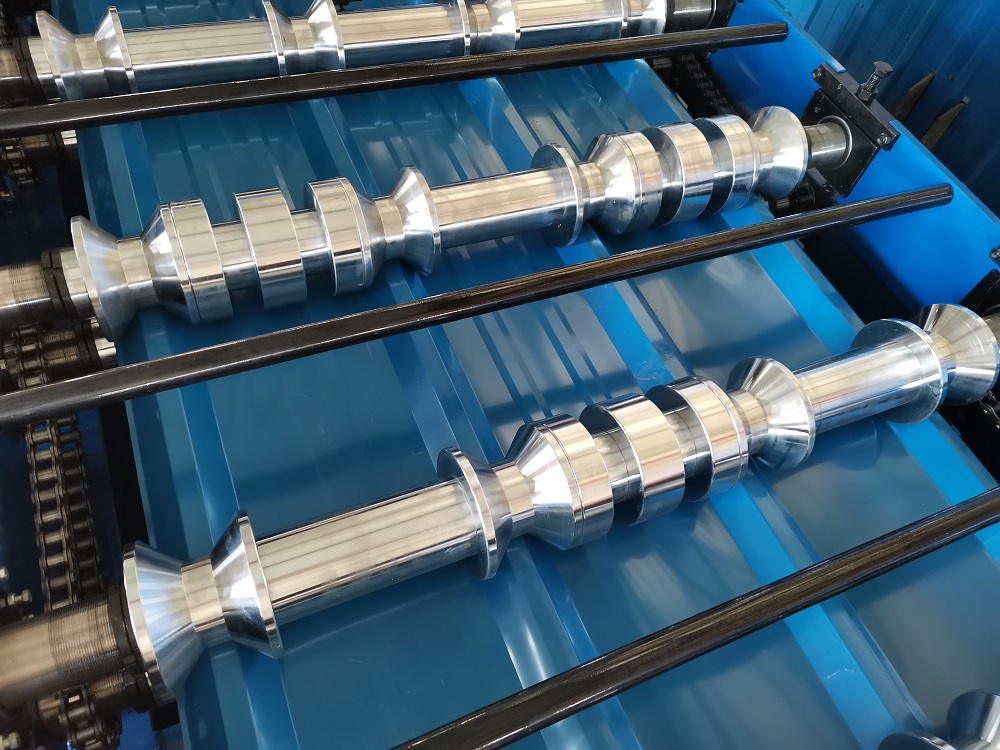

Understanding Roll Forming Technology

Roll forming is a continuous bending process in which metal strips are gradually shaped into desired profiles using a series of rollers. Metal roof panel roll forming machines are equipped with multiple roller stations that sequentially mold the metal sheet into specific configurations. These machines can handle various materials, including steel, aluminum, and copper, making them versatile tools in the roofing industry.

Customization at Its Finest

One of the standout features of custom metal roof panel roll forming machines is their ability to produce tailored roofing solutions. Each project may have unique requirements based on architectural design, climate considerations, and aesthetic preferences. With a roll forming machine, manufacturers can easily adjust the machine settings to create panels of different lengths, widths, thicknesses, and profiles. This customization capability ensures that contractors can source roofing materials that not only meet functional requirements but also complement the visual aspects of the building.

Efficiency and Speed

custom metal roof panel roll forming machine

Time is of the essence in construction projects, and the efficiency of metal roof panel roll forming machines directly contributes to faster project completion. Traditional roofing manufacturing methods can be slow and labor-intensive, often leading to delays. In contrast, roll forming machines can produce large quantities of roof panels in a fraction of the time. This efficiency does not compromise quality; in fact, the automated process often results in higher precision and consistent product quality, reducing waste and rework.

Cost-Effectiveness

Investing in a custom metal roof panel roll forming machine can yield substantial long-term cost savings. Although the initial investment may seem significant, the reduced labor costs, faster production times, and diminished material waste lead to overall lower expenses. Additionally, producing roofing panels in-house allows manufacturers to respond swiftly to market demands and fluctuations in material prices, enhancing their competitive edge.

Sustainability Benefits

As the construction industry increasingly prioritizes sustainability, metal roof panel roll forming machines align well with these goals. Metal roofs are known for their durability and recyclability, making them an environmentally friendly choice. Furthermore, machines that efficiently utilize raw materials contribute to reducing waste and energy consumption, thereby minimizing the overall carbon footprint of roofing operations.

Conclusion

The custom metal roof panel roll forming machine is a game-changer in the roofing industry, providing unparalleled customization, efficiency, and cost savings. As building projects continue to evolve, this technology offers solutions that cater to the diverse needs of architects, contractors, and homeowners. With its capacity to produce high-quality, tailored roofing panels at speed, the roll forming machine not only meets the demands of modern construction but also drives sustainability in building practices. Investing in this technology is a step forward for any business looking to thrive in an increasingly competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025