metal roofing sheet roll forming machine factory

The Evolution and Efficiency of Metal Roofing Sheet Roll Forming Machines

In the realm of modern construction, advancements in technology continue to shape the way building materials are produced, distributed, and installed. Among these innovations, metal roofing sheet roll forming machines have emerged as essential tools for manufacturers, providing efficiency, precision, and versatility in the production of roofing materials. This article delves into the nexus of metal roofing sheet roll forming machines and their pivotal role in the construction industry.

Understanding Metal Roofing Sheets

Metal roofing sheets are widely recognized for their durability, lightweight nature, and aesthetic appeal. Made from various metals, including steel, aluminum, and copper, these sheets are engineered to withstand harsh weather conditions, offer energy efficiency, and reduce maintenance costs. The demand for metal roofing has surged in recent years due to its sustainability, with many homeowners and builders opting for metal solutions to align with eco-friendly practices.

The Role of Roll Forming Machines

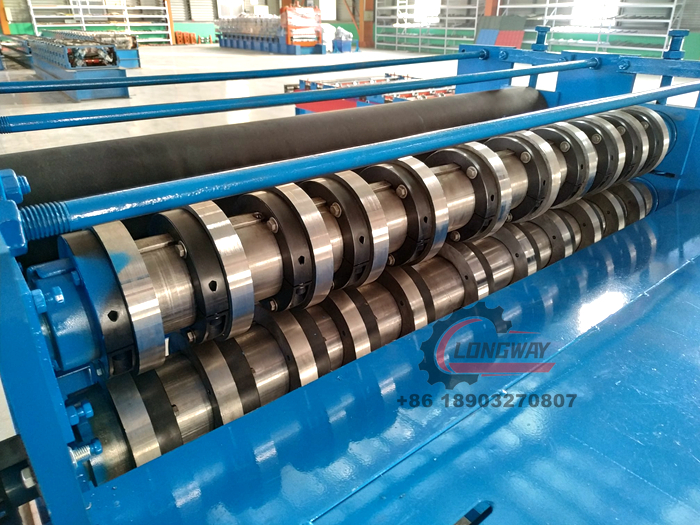

Roll forming machines are specialized equipment used to manufacture metal products with a continuous profile. The process involves feeding metal coils through a series of rollers that gradually shape them into specific designs. The efficiency of this method lies in its ability to produce long lengths of roofing material with consistent quality, minimizing waste and maximizing productivity.

Metal roofing sheet roll forming machines convert flat metal sheets into shaped profiles, such as standing seam or corrugated sheets, which are critical for different roofing applications. This transformation not only ensures uniformity in product quality but also allows for the customization of roofing materials to meet client specifications.

Advantages of Metal Roofing Sheet Roll Forming Machines

1. Efficiency and Speed One of the major advantages of using roll forming machines is their ability to produce roofing sheets quickly and efficiently. These machines can operate continuously, allowing manufacturers to increase output without compromising quality.

metal roofing sheet roll forming machine factory

2. Cost-Effectiveness While the initial investment in a roll forming machine may be significant, the long-term savings are substantial. The reduction in material waste, labor costs, and production time leads to a decrease in the overall cost of production, making metal roofing sheets more accessible to consumers.

3. Customization and Versatility Roll forming machines can be adjusted to produce a wide range of profiles, sizes, and thicknesses. This versatility enables manufacturers to cater to diverse architectural styles and customer preferences, offering products that meet specific functional and aesthetic requirements.

4. Durability and Strength The manufacturing process ensures that the finished roofing sheets retain the structural integrity and durability required for long-term performance. The continuous shaping process also promotes uniform thickness, enhancing the strength of the final product.

Innovations in Roll Forming Technology

As technology advances, so do the capabilities of metal roofing sheet roll forming machines. Recent innovations include the integration of automation and smart technology, which streamline production processes and enhance quality control. Automated systems can monitor the entire production line in real-time, allowing for immediate adjustments and minimizing errors.

Additionally, advancements in materials science have led to the development of high-performance alloys and coatings that improve the longevity and energy efficiency of metal roofing systems. With these innovations, manufacturers can produce roofing sheets that not only look great but also contribute to energy savings for end users.

Conclusion

The manufacturing of metal roofing sheets has been revolutionized by roll forming technology, allowing for increased efficiency, customization, and sustainability in construction practices. As the demand for durable and attractive roofing solutions continues to grow, metal roofing sheet roll forming machines will play a crucial role in meeting this demand. Manufacturers who invest in the latest technology and prioritize efficiency will undoubtedly lead the way in producing high-quality roofing materials for a rapidly evolving market. Investing in these machines is more than just purchasing equipment; it's about pioneering a future where construction meets modern demands for both durability and design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025