custom metal roofing sheet roll forming machine

Custom Metal Roofing Sheet Roll Forming Machine A Comprehensive Overview

In the evolving landscape of modern construction and architecture, roofing solutions play a pivotal role in ensuring the durability, aesthetic appeal, and energy efficiency of buildings. Among the most innovative developments in this field is the custom metal roofing sheet roll forming machine. This machine not only streamlines the production of roofing sheets but also caters to the diverse needs of builders and designers. In this article, we will delve into the functionalities, benefits, and applications of this advanced machinery.

Understanding the Roll Forming Process

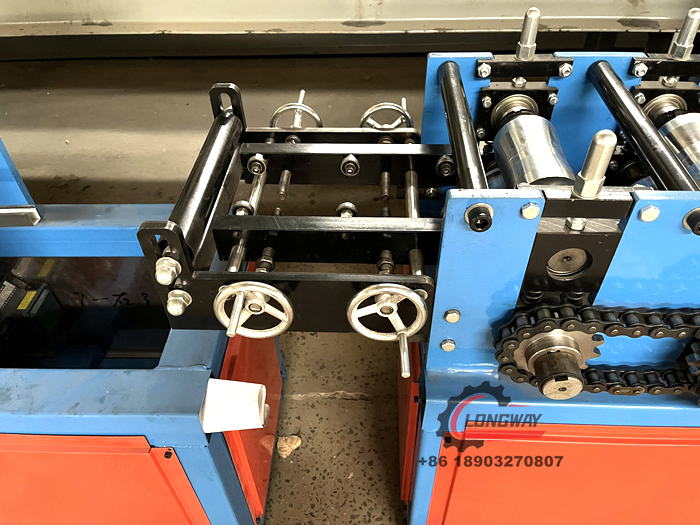

The roll forming process involves the continuous bending of a long strip of sheet metal into a desired cross-sectional profile. The custom metal roofing sheet roll forming machine utilizes a series of rollers to gradually shape the metal sheets as they pass through, creating uniform and precise roofing panels. This method is highly efficient, allowing manufacturers to produce large quantities of sheets with consistent quality and minimal waste.

Key Features of Custom Metal Roofing Sheet Roll Forming Machines

1. Customization Capabilities One of the standout features of these machines is their ability to produce custom profiles. Manufacturers can design roofing sheets to meet specific architectural requirements, accommodating variations in thickness, color, and surface texture. This flexibility is crucial for catering to the diverse demands of clients, ranging from residential homes to commercial buildings.

2. High Production Efficiency Custom metal roofing sheet roll forming machines are designed for high-speed production. They can operate continuously, producing roofing sheets rapidly without compromising on quality. This efficiency not only increases output but also reduces labor costs, making the entire process more economical.

3. Durability and Longevity Metal roofing is known for its durability and resistance to harsh weather conditions. The roll forming machines are capable of handling various metals, including steel and aluminum, which are renowned for their strength and longevity. Additionally, the machinery can apply protective coatings to enhance the resistance of the roofing sheets to corrosion and UV damage.

4. User-Friendly Operation Modern roll forming machines are equipped with advanced technology, including computerized controls and automated systems. This user-friendly interface allows operators to easily adjust settings, change production profiles, and monitor machine performance, ensuring optimal operational efficiency.

custom metal roofing sheet roll forming machine

Benefits of Using Custom Metal Roofing Sheet Roll Forming Machines

- Cost-Effectiveness By reducing labor costs and minimizing material waste, custom roll forming machines present a cost-effective solution for manufacturers. The ability to produce high volumes of roofing sheets also contributes to economies of scale, making it financially viable for businesses.

- Sustainability Metal roofing is an environmentally friendly choice due to its recyclability and energy efficiency. The roll forming process further enhances sustainability by reducing off-cuts and scrap materials, aligning with the growing global emphasis on green building practices.

- Aesthetic Versatility With a variety of profiling options, custom roll forming machines allow for the creation of aesthetically pleasing roofing solutions. This versatility is essential for architects and designers looking to integrate unique styles and designs into their projects.

Applications of Custom Metal Roofing Sheet Roll Forming Machines

Custom metal roofing sheet roll forming machines find extensive application in various sectors. These include residential roofing, commercial buildings, industrial facilities, agricultural structures, and even specialized projects such as modular homes and portable buildings. The adaptability of these machines ensures that they can meet the specific needs of different construction projects, paving the way for innovative architectural designs.

Conclusion

In summary, custom metal roofing sheet roll forming machines represent a crucial advancement in the metal roofing industry. With their ability to produce high-quality, customized roofing solutions efficiently, these machines are a valuable asset for manufacturers. Their contributions to sustainability, cost-effectiveness, and aesthetic versatility position them as essential tools in the ever-evolving construction landscape. As the demand for modern roofing solutions continues to rise, roll forming technology will undoubtedly play a key role in shaping the future of architecture and construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025