aluminium roll forming machine factories

Exploring the World of Aluminium Roll Forming Machine Factories

Aluminium roll forming machines have become a vital part of the manufacturing industry, particularly in sectors such as construction, automotive, and aerospace. These machines transform aluminium coils into profiles that are essential for various applications, from structural components to decorative trim. As the demand for lightweight, durable materials continues to rise, so does the importance of aluminium roll forming machine factories.

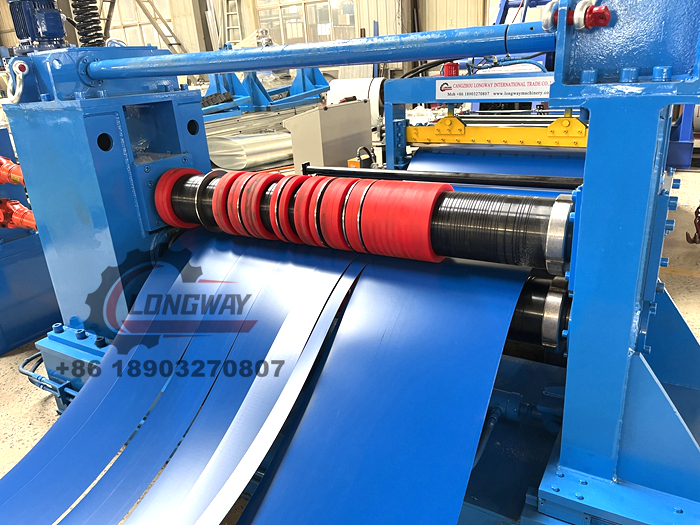

One of the key aspects of these factories is their ability to produce high-quality aluminium products with precision and efficiency. Aluminium is known for its excellent strength-to-weight ratio, corrosion resistance, and malleability, making it an ideal material for a multitude of applications. Factories specializing in aluminium roll forming are equipped with advanced machinery that enables them to create complex shapes and designs. The roll forming process involves passing a flat strip of aluminium through a series of rollers that gradually shape it into the desired profile. This continuous process not only enhances efficiency but also reduces material waste, making it an environmentally friendly option for manufacturers.

In recent years, there has been a significant shift towards automation in aluminium roll forming factories. Automated systems improve production rates and reduce the likelihood of human error, ensuring a consistent product quality. Moreover, modern factories often integrate computer numerical control (CNC) technology, which allows for intricate designs and customization. This capability is particularly beneficial for industries that require specific dimensions and tolerances, such as the automotive sector.

aluminium roll forming machine factories

Another significant advantage of aluminium roll forming machine factories is their adaptability to various market needs. These facilities can be designed to handle different types of aluminium alloys and can easily switch between product lines. This flexibility is crucial in a fast-paced market where consumer preferences and technological advancements can change rapidly. By investing in versatile roll forming machinery, factories can not only meet existing demands but also explore new opportunities.

Globalisation has also played a critical role in the growth of aluminium roll forming machine factories. Many manufacturers are now sourcing materials from different parts of the world, allowing them to lower production costs while maintaining high standards. This interconnectedness fosters collaboration and innovation, leading to the development of better roll forming technologies and practices.

Furthermore, the commitment to sustainability is increasingly becoming a focal point for these factories. As industries worldwide strive to reduce their carbon footprints, aluminium's recyclability makes it an attractive option. Many factories are now adopting practices that support recycling and waste reduction, aligning themselves with global sustainability goals.

In conclusion, aluminium roll forming machine factories are at the forefront of modern manufacturing, providing crucial support to various industries. With advances in technology, automation, and a focus on sustainability, these factories are poised to meet the evolving challenges of the market. As the need for efficient and durable materials continues to grow, the significance of aluminium roll forming will only increase, driving innovation and performance in manufacturing processes worldwide.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025