custom machine for roofing sheet

Custom Machines for Roofing Sheets Innovation in the Building Materials Industry

In the ever-evolving landscape of the construction and manufacturing industries, the advancement of technology plays a crucial role in enhancing productivity and efficiency. One of the most significant innovations in recent years is the development of custom machines for roofing sheets. These machines are designed to meet the specific needs of manufacturers, enabling them to produce roofing materials that are tailored to the demands of modern construction.

Understanding Roofing Sheets

Roofing sheets are critical components in the building industry, providing essential protection against the elements while also contributing to the aesthetic appeal of structures. They come in various materials such as metal, asphalt, and plastic, each offering unique advantages. Given the diversity of roofing applications—ranging from residential homes to industrial buildings—the demand for roofing sheets that are both durable and visually pleasing is on the rise.

The Need for Custom Machinery

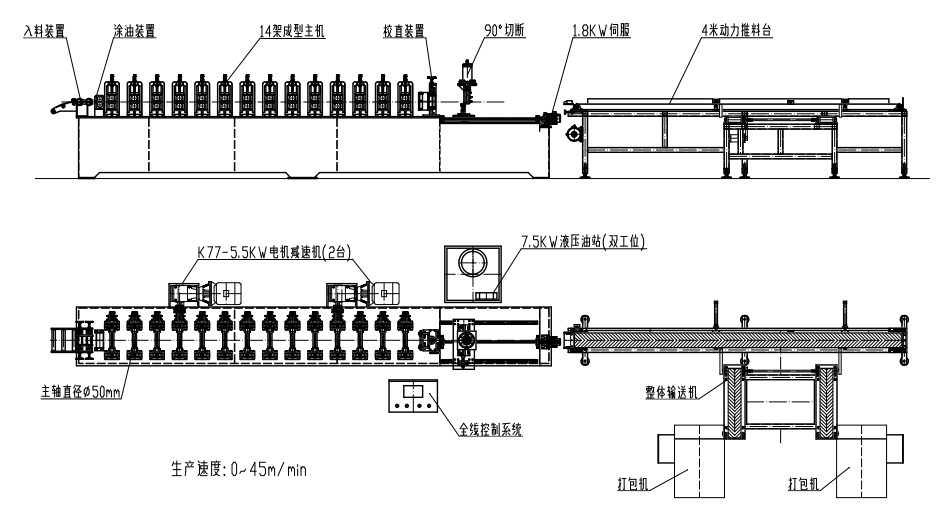

As the construction industry continues to grow, so does the need for efficient production processes. Off-the-shelf machines often fail to meet the specific requirements of manufacturers, leading to inefficiencies and increased production costs. Custom machines for roofing sheets address this challenge by allowing manufacturers to produce roofing materials of varying sizes, shapes, and materials. This level of customization can be vital to meeting specific project demands, accommodating unique architectural designs, and adhering to local building regulations.

Advantages of Custom Machines

1. Increased Efficiency Custom machines are designed to streamline the production process, reducing downtime and increasing output. Manufacturers can optimize their workflows, ensuring that each stage of the roofing sheet production is as efficient as possible.

custom machine for roofing sheet

2. Quality Control With tailored machines, manufacturers can maintain higher standards of quality control. Custom machinery can be equipped with advanced technology for monitoring and controlling dimensions, ensuring that each sheet produced meets strict quality standards.

3. Flexibility in Design The ability to create bespoke roofing sheets allows manufacturers to cater to specific customer preferences. Whether it’s a unique profile, color, or material, custom machines make it possible to experiment with various designs to meet market demands.

4. Cost-Effectiveness Although the initial investment in custom machinery may be higher than purchasing standard equipment, the long-term benefits can outweigh these costs. By reducing waste, optimizing production speeds, and minimizing the need for additional labor, custom machines can lead to significant savings over time.

5. Adaptability The construction industry is subject to changing trends and regulations. Custom machines provide the flexibility needed to adapt to these shifts, allowing manufacturers to modify their production lines as necessary without significant overhauls.

Conclusion

The introduction of custom machines for roofing sheets marks a transformative step in the manufacturing processes within the construction industry. By focusing on efficiency, quality control, flexibility, and cost-effectiveness, these machines not only meet the needs of modern builders but also pave the way for innovative architectural designs.

As technology continues to advance, the potential for further enhancements in machine customization is promising. Manufacturers who invest in custom machinery poised to adapt to industry changes will be at the forefront of the roofing materials market, ready to seize new opportunities and deliver exceptional products in an increasingly competitive environment. Investing in custom machinery is not just about keeping up with the current trends; it’s about shaping the future of roofing materials and contributing positively to the construction industry as a whole.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025