roof tile making machine manufacturers

The Rise of Roof Tile Making Machine Manufacturers

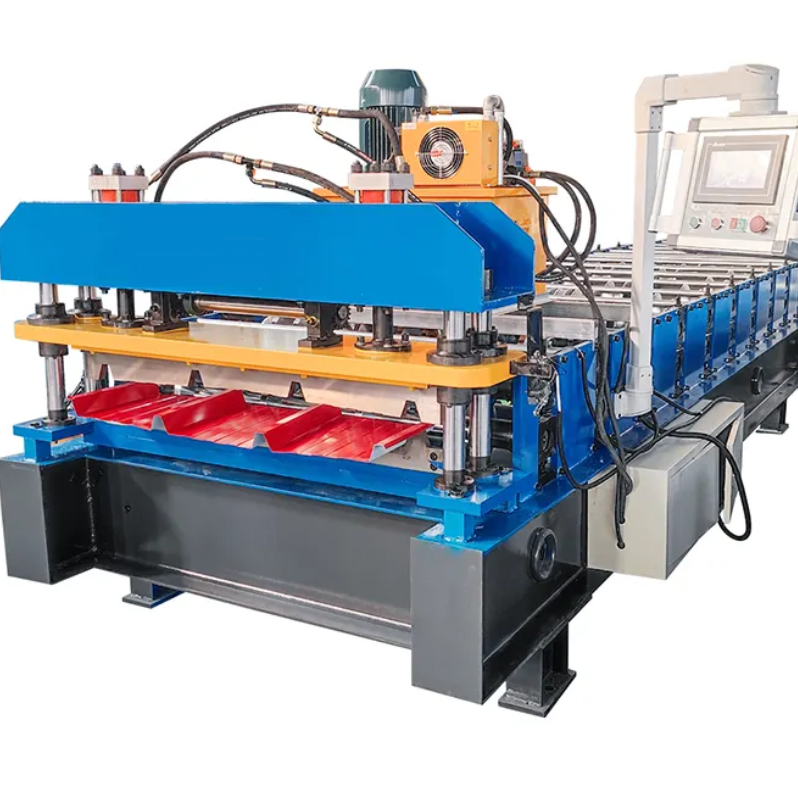

In recent years, the construction industry has witnessed a significant transformation, particularly in the production of roofing materials. Among various advancements, roof tile making machines have emerged as pivotal equipment for manufacturers aiming to meet the increasing demand for quality roof tiles. These machines not only enhance production efficiency but also ensure high-quality outputs that are crucial for modern architectures.

Roof tile making machines come in various types and sizes, ranging from manual machines for small-scale operations to fully automated production lines that cater to large manufacturers. The market for roof tile making machines has seen a surge, driven by the growing construction activities around the globe. Urbanization and the need for durable, aesthetically pleasing roofing options have prompted builders to seek innovative solutions, making roof tiles a preferred choice for many projects.

One of the key advantages of modern roof tile making machines is their ability to produce various tile designs and materials, including clay, concrete, and composite tiles. This versatility allows manufacturers to cater to diverse customer needs. Additionally, advancements in technology have led to the integration of automation and robotics in these machines, which significantly reduces labor costs and production time while improving precision and consistency.

Moreover, sustainability is becoming an increasingly important consideration in the construction industry. Many roof tile making machine manufacturers are now focusing on eco-friendly production processes that minimize waste and energy consumption. Innovative technologies, such as using recycled materials in the tile-making process, are gaining traction. This not only meets the growing consumer demand for green products but also helps manufacturers comply with strict environmental regulations.

roof tile making machine manufacturers

For new entrants in the market, choosing the right roof tile making machine is crucial. Factors such as production capacity, the range of products, automation level, and maintenance requirements must be carefully evaluated. Leading manufacturers typically offer comprehensive service packages, including installation, training, and after-sales support, which are essential for efficient operation and optimal machine performance.

The competitive landscape of roof tile making machine manufacturers is marked by a constant evolution of technology and business strategies. Companies are increasingly leveraging digital tools for marketing and customer engagement. Online platforms provide manufacturers with a broader reach, allowing them to showcase their products effectively and connect with a global audience.

As the demand for roofing solutions continues to grow, the future of roof tile making machine manufacturers looks promising. Continuous innovation and adaptation to market trends will be critical for those looking to thrive in this competitive industry. Moreover, with the advent of smart technologies, we can expect further advancements in machine capabilities, enhancing the quality and sustainability of roofing materials.

In conclusion, roof tile making machines represent a vital component of the modern construction industry. By embracing innovation, prioritizing sustainability, and meeting evolving customer needs, manufacturers in this sector can secure their place in the market while contributing to building a more resilient and aesthetically pleasing urban landscape. The journey of roof tile making machine manufacturers is indeed one of growth, opportunity, and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025