Custom Gypsum Wall Partition Profile Shaping Machinery for Efficient Construction Solutions

Custom Drywall Partition Profile Forming Machine Revolutionizing Construction Efficiency

In the ever-evolving world of construction, efficiency and precision are paramount. One of the key advancements that have significantly transformed this landscape is the introduction of custom drywall partition profile forming machines. These innovative machines are designed to streamline the production of drywall profiles, ensuring that the construction process is not only faster but also more cost-effective and environmentally friendly.

Understanding Drywall Partition Profiles

Drywall partition profiles are essential components used in the assembly of interior walls in commercial and residential buildings. They serve as the framework that supports the drywall panels, providing structural integrity and stability. The traditional method of constructing these profiles can be labor-intensive and time-consuming, often resulting in wasted materials and increased costs. The advent of custom drywall partition profile forming machines addresses these challenges head-on.

The Advantages of Custom Machines

One of the most significant benefits of using a custom drywall partition profile forming machine is its ability to produce profiles tailored to specific project requirements. Unlike mass-produced profiles, custom machines can create unique sizes, shapes, and designs that meet the exact needs of a construction project. This flexibility not only enhances design creativity but also minimizes waste, as builders can create profiles that fit perfectly without excess material.

Increased Efficiency and Speed

Time is money in the construction industry, and custom drywall partition profile forming machines significantly reduce production time. These machines can operate at high speeds, producing large quantities of profiles in a fraction of the time it would take using manual methods. This increase in efficiency allows construction projects to stay on schedule, leading to faster turnaround times and reduced labor costs.

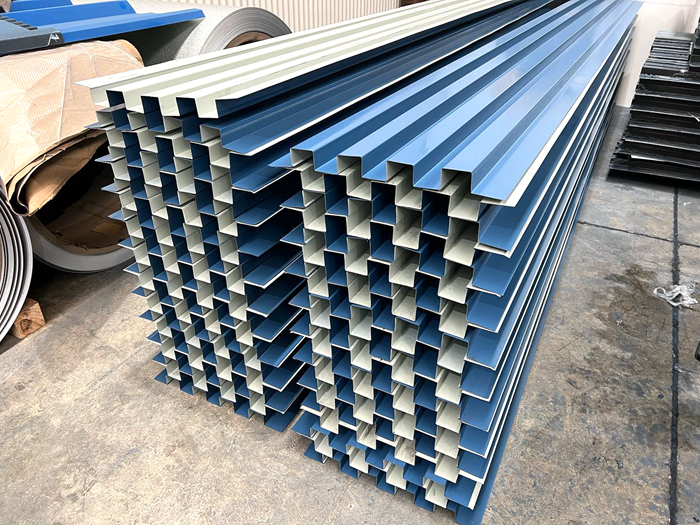

custom drywall partition profile forming machine

Enhanced Precision and Quality

Precision is crucial when it comes to constructing drywall partitions. A slight miscalculation can lead to misalignment, requiring time-consuming adjustments and repairs. Custom drywall partition profile forming machines utilize advanced technology to ensure high levels of accuracy in profile production. This precision not only enhances the quality of the finished structure but also increases the overall safety of the building by ensuring that all components fit together seamlessly.

Eco-friendly Practices

As the construction industry faces increasing scrutiny regarding its environmental impact, custom drywall partition profile forming machines offer a more sustainable approach. By minimizing material waste and enabling the use of recycled materials, these machines help reduce the carbon footprint of construction projects. Furthermore, as energy-efficient technologies continue to develop, many modern machines consume less power, contributing to a greener construction process.

Customization and Design Flexibility

Incorporating custom solutions in interior design has become an essential trend in modern architecture. The ability to create bespoke drywall profiles allows architects and designers to explore innovative designs without the limitations often imposed by standard profiles. From curved shapes to intricate designs, custom machines can accommodate various design styles, making them an invaluable asset in both residential and commercial projects.

Conclusion

The introduction of custom drywall partition profile forming machines marks a significant milestone in the construction industry. By combining efficiency, precision, and sustainability, these machines offer an innovative solution to the challenges faced in drywall construction. As the industry continues to embrace technological advancements, we can expect that the role of custom drywall partition profile forming machines will only grow, paving the way for a new era of construction where design possibilities are limitless, and efficiency is at the forefront. For contractors, builders, and architects looking to enhance their projects, investing in a custom drywall partition profile forming machine could be the key to unlocking new levels of productivity and creativity.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025