Leading Manufacturers of Roll Forming Machines for Precision Fabrication Solutions

The Evolution and Importance of Roll Forming Machine Manufacturers

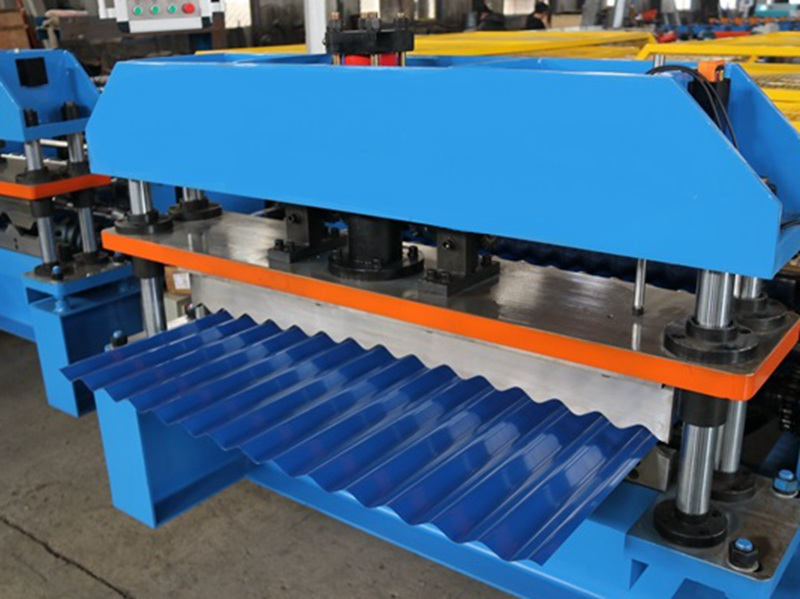

In the world of manufacturing, efficiency and precision are paramount for creating high-quality products. One of the specialized processes that has gained notable significance in various industries is roll forming. This process transforms flat metal sheets into complex shapes through a series of die sets, and it has become increasingly essential in the production of everything from automotive parts to structural components. As a result, the role of roll forming machine manufacturers is critical in ensuring businesses can meet their production needs effectively.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers to progressively shape it into the desired cross-section. This process is highly efficient for producing large volumes of parts with consistent dimensions and excellent surface quality. Various materials, including steel, aluminum, and other alloys, can be used, and the flexibility of the process allows manufacturers to create intricate designs that cater to specific applications.

Key Advantages of Roll Forming Machines

Roll forming machines offer numerous advantages that make them appealing to manufacturers. Firstly, they provide high production rates, which can significantly reduce production lead times. Additionally, because these machines can operate continuously, manufacturers can optimize productivity while minimizing labor costs.

Another significant benefit is the material utilization efficiency. Roll forming can generate minimal waste compared to other metalworking processes, such as stamping or cutting, where considerable scrap material may be produced. This not only lowers material costs but also aligns with sustainable manufacturing practices, a growing concern in today's eco-conscious market.

With the capability to produce complex shapes and profiles, roll forming machines enable manufacturers to explore new design possibilities without sacrificing structural integrity or quality. By adapting to various specifications, including lengths, widths, thicknesses, and materials, roll forming can cater to diverse industries such as automotive, construction, furniture, and appliance manufacturing.

The Role of Manufacturers

roll forming machine manufacturers manufacturer

As demand for customized metal profiles continues to grow, the importance of reliable roll forming machine manufacturers cannot be overstated. These manufacturers are tasked with the responsibility of designing and engineering advanced roll forming equipment that meets contemporary production requirements.

Leading roll forming machine manufacturers invest heavily in research and development to innovate their machines, incorporating technology that enhances automation, precision, and flexibility. Modern roll forming machines are often equipped with programmable control systems, which allow manufacturers to quickly switch between different production runs while ensuring consistency and accuracy.

Moreover, the experience of the manufacturer plays a significant role in the performance of the roll forming machines. Established manufacturers understand the nuances of metal properties and process variables that can affect the outcome, ensuring that their machines are fine-tuned for optimal performance.

Challenges and Considerations

Despite the numerous advantages, roll forming machine manufacturers face challenges that must be addressed in their designs and offerings. For instance, the initial investment cost of roll forming equipment can be considerable, which may deter smaller manufacturers from adopting this technology.

Additionally, training and expertise in operating and maintaining such sophisticated machinery are critical. Manufacturers must ensure that their customers are well-supported and informed about the technical aspects of their machines.

Conclusion

In conclusion, roll forming machine manufacturers play a vital role in facilitating efficient and innovative manufacturing processes across numerous industries. As technology continues to evolve, these manufacturers must adapt and innovate, ensuring that businesses have access to the latest advancements in roll forming technology. By focusing on quality, efficiency, and customer support, roll forming machine manufacturers not only enhance their competitive edge in the market but also contribute to the broader trends of modernization and sustainability in manufacturing. As industries look towards the future, the importance of these specialized manufacturers will undoubtedly grow, solidifying their position as key players in the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025