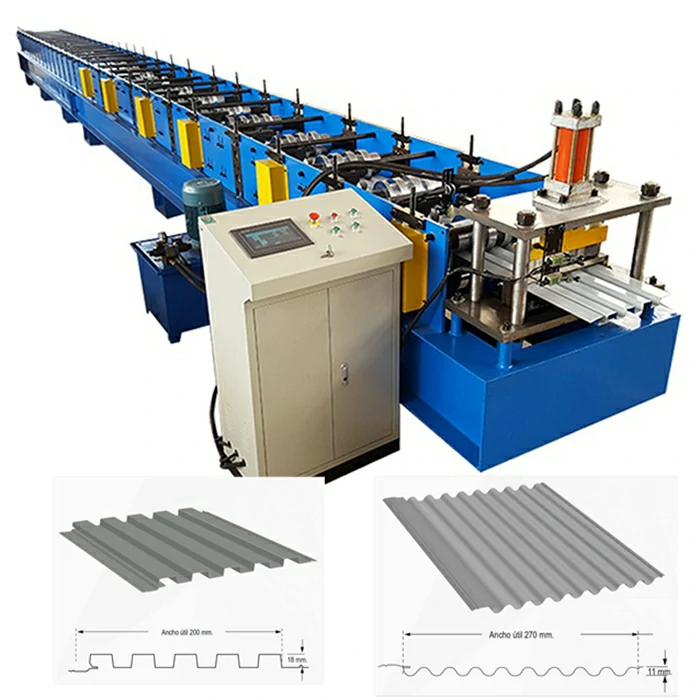

custom channel forming machine

The Evolution and Importance of Custom Channel Forming Machines

In the dynamic landscape of manufacturing, custom channel forming machines have emerged as pivotal tools that enhance efficiency and precision. These machines are designed to create a variety of metal channels used in construction, automotive, electronics, and numerous other industries. As the demand for customized solutions continues to grow, so too does the significance of these machines in modern production lines.

Understanding Channel Forming Machines

Channel forming machines are specialized equipment that manipulate metal coils into a variety of structural shapes. They utilize rolls and dies to shape and cut the metal as it passes through the machine. The versatility of these machines allows for the production of different channel sizes and shapes, including U-channels, C-channels, and other geometric profiles tailored to specific applications.

The custom aspect comes into play when manufacturers need to create channels that meet specific requirements rather than sticking to standard dimensions. Whether it is for unique architectural features or specialized components in machinery, custom channel forming machines are essential for meeting diverse client needs within a competitive market.

Key Features of Custom Channel Forming Machines

Custom channel forming machines are equipped with various features that enhance their performance and capabilities

1. Modularity Many machines can be easily adjusted or outfitted with additional tooling to create different channel profiles without requiring an entirely new machine. This modularity allows manufacturers to switch between projects with ease.

2. Precision Engineering With advancements in technology, modern channel forming machines incorporate precision engineering techniques, such as computer numerical control (CNC). This ensures tight tolerances and consistent quality across batches, essential for industries where safety and standards are paramount.

3. High-Speed Production Speed is often a crucial factor in manufacturing. Custom channel forming machines can operate at high speeds, drastically reducing lead times while maintaining accuracy, enabling companies to fulfill orders swiftly.

custom channel forming machine

4. User-Friendly Interfaces Advances in industrial automation have led to the development of user-friendly interfaces, allowing operators to program and monitor the machines with greater ease. This minimizes the learning curve and boosts overall productivity.

Applications of Custom Channel Forming Machines

The applications of channel forming machines are vast. In the construction industry, they play a critical role in creating frames, supports, and brackets that form the backbone of many structures. In the automotive sector, they are employed to manufacture components such as chassis supports and structural reinforcements that contribute to vehicle safety and performance.

Moreover, custom channel forming machines are increasingly used in the electronics industry for producing enclosures and mounting hardware that protect sensitive components while providing necessary structural integrity. The versatility and adaptability of these machines ensure they remain a staple in various manufacturing processes.

The Future of Custom Channel Forming Machines

As technology continues to evolve, so too will the capabilities of custom channel forming machines. The integration of artificial intelligence and machine learning could lead to automated adjustments based on real-time data, further optimizing production efficiency. Additionally, as sustainability becomes a major focus across industries, these machines will likely incorporate eco-friendly practices, including energy-efficient designs and reduced waste generation.

Furthermore, the rise of Industry 4.0 emphasizes the need for interconnected machines and smart factories. Custom channel forming machines may soon be part of a fully integrated production line where data analytics and machine interconnectivity enhance operational efficiency.

Conclusion

In conclusion, custom channel forming machines are vital to modern manufacturing, offering flexibility, precision, and speed. Their ability to create tailored solutions for various industries underscores their importance in a competitive market. As technological advancements continue to shape the manufacturing landscape, these machines are poised to become even more integral to future production processes, ensuring that manufacturers can meet the ever-evolving demands of their clients. Embracing these innovations will be key to maintaining a competitive edge in the global marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025